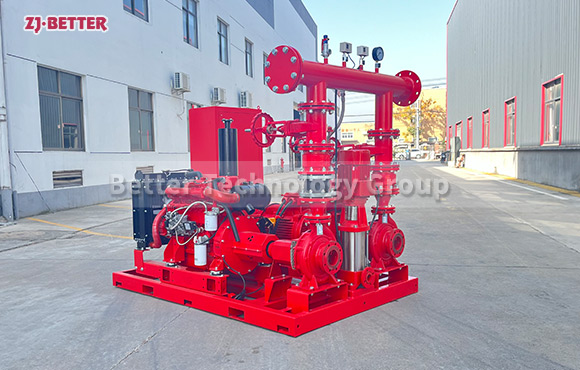

Performance and advantages of EDJ series fire diesel electric fire pump unit

The EDJ series fire diesel electric fire pump unit (fire dual power pump unit) is based on the traditional fire protection system of GEM, which combines electric fire pump, booster regulator pump, diesel fire pump, regulator tank and supporting valves, Piping is combined on the same skid-mounted common base. The pump set can provide safety guarantee for fire emergency, and the diesel engine has the function of speed regulation, which makes the use and adjustment range of the unit equipment more extensive.

1. It has perfect starting function: manual starting function, remote signal starting, automatic starting, automatic exit from starting state, emergency manual direct starting function.

2. When a fire occurs, in case of electric pump failure or power failure, resulting in inability to operate, the system will automatically call the diesel fire pump to ensure the normal operation of the equipment.

3. After the water pump unit receives an effective fire protection signal, if the power supply system of the motor fire pump is out of power or lacks phase or the electric pump fails to start normally, the diesel engine fire pump unit will automatically start and run. Once the power supply system returns to normal or the electric pump can be During normal operation, it will automatically switch to the electric pump by default next time.

4. The fire signal can be fed back to the fire control room to facilitate remote monitoring and control.