Intelligent Diesel Pump Control System | Auto Start-Stop with Multi-Layer Alarms

The intelligent diesel pump control system features auto start-stop, multi-alarm protection, remote communication, and smart maintenance—enhancing fire pump performance and safety for petrochemical, power, and industrial applications.

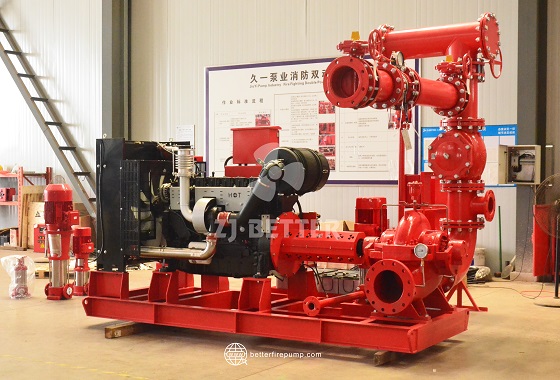

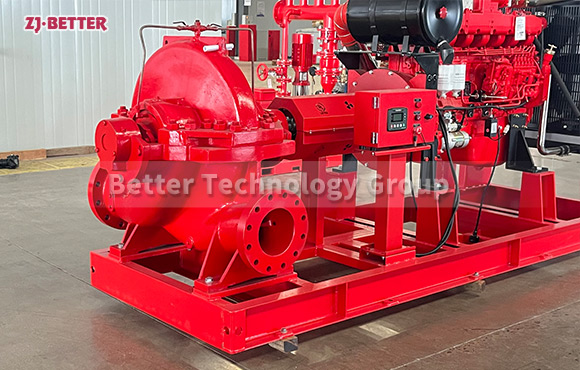

In modern industrial safety systems, diesel-driven fire pumps are widely utilized in petrochemical plants, warehouses, power stations, ports, and various high-risk environments due to their independence from the power grid. To maximize the operational efficiency and reliability of these pumps, an intelligent control system is essential. Our product—the “Intelligent Diesel Pump Control System”—is a high-reliability solution developed to meet the demanding safety requirements. It integrates automatic start-stop logic, real-time data monitoring, multi-alarm protection, and remote communication functions, providing a powerful intelligent core for fire safety systems.

This control system adopts an industrial-grade PLC architecture, with all control logic programmed in compliance with fire safety standards. It supports fully automatic start, operational monitoring, fault self-diagnosis, and shutdown control for diesel pumps, ensuring rapid intervention during fire emergencies. The built-in sensor modules collect key data such as engine oil pressure, coolant temperature, battery voltage, and engine speed in real time. These are visualized via an HMI (Human-Machine Interface), enabling users to monitor the pump’s status clearly. Furthermore, the control box is equipped with a multi-level audible and visual alarm system that immediately triggers alerts upon abnormal parameters and logs error codes for future analysis.

Another core advantage of the intelligent diesel pump control system lies in its remote communication and centralized control capabilities. The system includes standard communication interfaces such as Modbus, RS485, and CAN, enabling seamless integration with Building Automation Systems (BAS), fire control centers, or cloud-based platforms. This makes it ideal for applications requiring unified control across multiple sites—such as oil storage tank farms, large-scale logistics warehouses, and industrial clusters. Remote start-stop commands and centralized data acquisition significantly enhance coordination in fire response operations.

In terms of safety design, all I/O modules, power modules, and relays are protected against interference and short circuits. The internal wiring complies with IEC and GB standards, offering excellent electromagnetic compatibility and effectively preventing system malfunctions caused by power surges or lightning strikes. The control cabinet is made of high-strength carbon steel with powder coating, providing dustproof, waterproof, and corrosion-resistant performance. It meets IP55 protection standards, making it suitable for long-term indoor and outdoor use in harsh environments.

Additionally, the system features an “Intelligent Maintenance Management” function. Based on pump runtime and start-stop frequency, it automatically calculates the maintenance cycle and prompts users for regular inspections—such as filter replacement, battery testing, and lubrication checks—helping to prevent failures caused by human negligence. The system also supports USB data export and SD card local storage, facilitating operational report analysis and annual fire inspection archiving.

In terms of adaptability, the intelligent diesel pump control system is compatible with various types of diesel pumps, including horizontal end-suction pumps, horizontal multistage pumps, and vertical long-shaft pumps. It is widely applicable in petrochemical storage, oil and gas refueling stations, tunnels and utility corridors, power plant cooling systems, and remote fire stations. Its modular design allows flexible expansion of control nodes based on project scale, supporting multiple application modes such as one-to-one, one-to-many, and redundant backup control.

In summary, this intelligent diesel pump control system establishes a stable, efficient, intelligent, and easily manageable fire pump operation platform through its six core features: automated control, real-time monitoring, remote communication, multi-alarm protection, safety design, and intelligent maintenance. It is especially suitable for modern industrial fire protection systems with high demands for safety, rapid response, and ease of maintenance, serving as a key enabler of digital and intelligent fire safety management.