Integrated Diesel Fire Pump Unit | Smart Auto Start-Stop for Uninterrupted Industrial Protection

Advanced integrated control diesel fire pump with auto start-stop, remote monitoring, and multiple safety alarms—ideal for factories, warehouses, petrochemical, and energy sectors to ensure uninterrupted industrial fire protection.

In modern industrial safety systems, the importance of fire protection systems cannot be overstated. Especially in high-risk environments such as those with high temperatures, flammable materials, or unmanned operations, the response speed and operational stability of fire protection systems directly impact the safety of lives and property. Traditional fire pump systems often rely on manual activation and monitoring, which not only reduces efficiency but also poses risks of delays and malfunctions. With the rise of intelligent industry, automated and integrated fire pump solutions have increasingly become the mainstream choice. Among these, integrated control-type diesel fire pumps, with their high level of automation, robust durability, and comprehensive monitoring capabilities, have become the preferred equipment for high-end industrial facilities.

The system utilizes a high-efficiency diesel engine as its power core, ensuring stable operation even during power outages or electrical system failures. Compared to conventional fire pumps, integrated control diesel fire pumps are equipped with automatic start/stop systems, fault self-diagnosis modules, multi-point sensor monitoring, redundant power switching devices, and intelligent remote management platforms. These functional modules not only ensure immediate response during the initial stages of a fire but also enable 24/7 monitoring and control in unmanned conditions, truly achieving “automatic operation, intelligent management, and continuous protection.”

The control core of the equipment uses an industrial-grade PLC controller with powerful logical computing and stable performance, enabling seamless integration with building fire systems, fire detection alarm systems, and industrial central control systems. The built-in program can automatically determine whether to start or stop the pump set based on fire alarm signals, pressure sensor readings, and user-defined parameters, avoiding unnecessary starts or stops that could waste resources or disrupt the system.

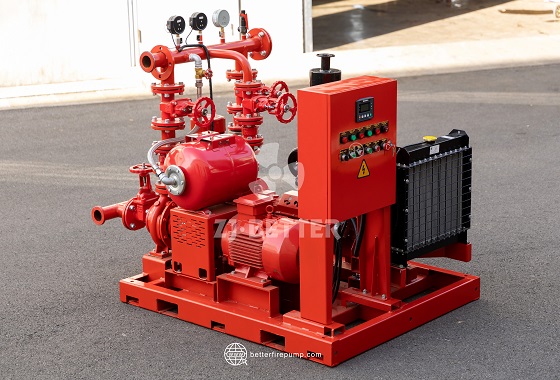

In terms of structural design, the fire pump set adopts a modular integrated layout, integrating components such as the diesel engine, water pump, control system, cooling system, buffer tank, battery pack, and fuel supply system onto a single base, significantly reducing the footprint and installation complexity, and facilitating rapid deployment in various industrial settings such as factories, warehouses, power plants, and chemical workshops. The pump set base is constructed from thickened carbon steel, treated with sandblasting corrosion protection and heavy-duty protective coatings, ensuring exceptional environmental adaptability and enabling long-term stable operation in harsh conditions such as high temperatures, humidity, dust, and corrosive gases.

To enhance equipment operational life and safety, the system incorporates multiple safety protection mechanisms, including high-temperature alarms for the cooling system, low lubricating oil pressure alarms, low fuel level warnings, limits on failed start attempts, battery voltage monitoring, and power failure protection, comprehensively covering potential operational anomalies. All alarm information can be displayed in real-time via a touchscreen and uploaded to a remote monitoring system through communication interfaces, enabling automated warning management.

The device also supports multiple communication protocols, enabling users to remotely monitor operating status, control start/stop functions, view historical data, and download operation reports, seamlessly integrating with smart factory management platforms. Additionally, manufacturers can remotely assist with commissioning or fault diagnosis, reducing maintenance costs and improving service efficiency.

In summary, the integrated control-type diesel fire pump seamlessly integrates power, control, safety, and communication functions. While ensuring the core functionality of the fire protection system, it achieves a perfect balance of intelligence, automation, and high reliability. It represents not only an upgrade at the equipment level but also a revolutionary shift in safety management philosophy, making it an indispensable piece of equipment for modern chemical, energy, and manufacturing industries as they transition toward “smart fire protection.”