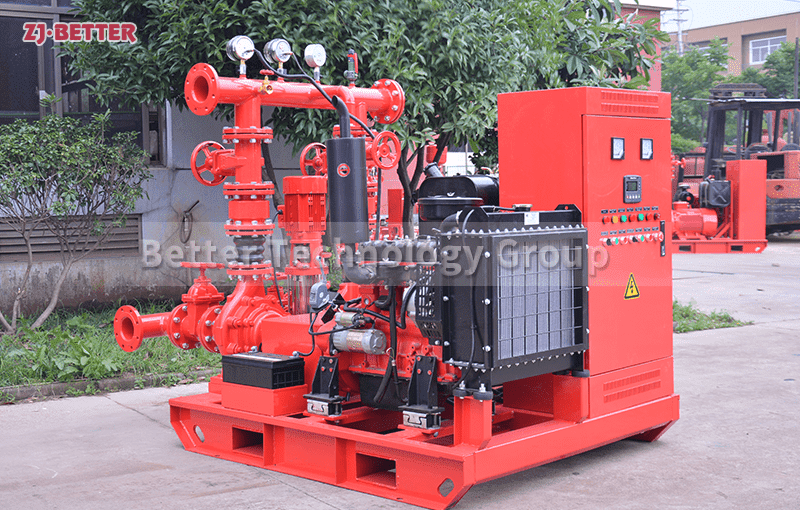

Heavy-Duty Fire Pump System Solutions for Harsh Environments

High-efficiency electric fire pumps feature stable pressure output, corrosion-resistant structure, and long service life, making them a reliable water supply solution for high-rise buildings, industrial facilities, and fire protection systems.

Heavy-duty fire pump system solutions for harsh environments are a type of professional fire water supply equipment designed specifically for scenarios with high intensity, high corrosiveness, high temperature differences, and high continuous operation requirements. These fire pumps have a robust structure, sufficient power, and stable operation, and can continuously provide stable pressure and flow even under extreme conditions to ensure that critical facilities receive reliable water supply support in the event of a fire, thereby protecting life safety, property safety, and the stability of important projects. To meet the needs of such harsh environments, the overall design of the equipment, from pump body structure, material selection, power configuration, sealing system to installation method, has been strengthened and optimized to ensure that it can maintain performance without degradation under long-term high-load operation and demonstrate excellent adaptability in various complex application scenarios. For example, the fire protection system requirements in chemical plants, coastal salt spray areas, outdoor exposure scenarios, high dust environments, extreme temperature difference locations, underground spaces, large warehouses, ports and docks, power plants, and high temperature and humidity conditions all place higher standards on fire pumps. Therefore, heavy-duty fire pumps are one of the key equipment providing solutions for these high-requirement projects. The core advantages for use in harsh environments are primarily reflected in its high-strength structural design. The pump body uses high-strength castings and undergoes professional processing to enhance its impact and wear resistance. Meanwhile, the pump shaft is made of high-quality steel and undergoes heat treatment or surface strengthening, making it less prone to bending or fatigue under long-term high-speed operation. The impeller uses precision casting technology to ensure structural stability and improve hydraulic efficiency, maintaining stable performance even when handling fire water sources containing trace impurities. The mechanical strength of the entire pump section is far higher than that of ordinary fire pumps, ensuring stable and reliable operation under harsh conditions such as earthquakes, mechanical vibrations, and frequent starts. The base uses a thickened steel structure and undergoes anti-corrosion treatment, making the installation stable and providing stronger seismic resistance, capable of withstanding various external impacts and loads from the site. Secondly, material corrosion resistance is crucial for adapting to harsh environments. To cope with special scenarios such as humidity, high salt spray, and chemical corrosion, the equipment exterior is reinforced with corrosion-resistant spraying or epoxy coating. Depending on project requirements, stainless steel impellers, stainless steel shafts, and stainless steel pump body liners can be selected to enhance corrosion resistance, improving stability and lifespan in long-term use in coastal and chemical environments. Simultaneously, the sealing system employs wear-resistant mechanical seals and multiple sealing structures to effectively prevent leakage problems caused by long-term operation, maintaining ideal sealing performance under continuous operation conditions, extending maintenance cycles, and reducing downtime probability. The power unit uses a high-performance motor equipped with an enlarged cooling structure, ensuring the motor maintains a low-temperature rise even in high-temperature, high-humidity, or continuous operation environments, preventing damage due to motor overload. Furthermore, the motor’s insulation class is typically upgraded to F or higher, enabling it to adapt to conditions with large temperature differences, high humidity, or dense dust, ensuring pump stability and reliability even in scenarios requiring long-term continuous operation. In terms of performance output, heavy-duty fire pumps feature high flow rate, high head, and high efficiency, enabling them to quickly establish and maintain the pressure required by the system. This meets the diverse water delivery needs of fire hydrant systems, sprinkler systems, and water curtain systems. Especially in large-scale projects, long pipelines, high-rise buildings, and multi-point water supply require pumps with stronger head capacity and stability to prevent system failure due to pressure decay. These pumps optimize hydraulic models to maintain low vibration, low noise, and high efficiency even at high head operation, thereby reducing energy consumption and extending service life. Furthermore, heavy-duty fire pumps typically support intelligent control systems, which can be integrated with automatic control cabinets to achieve automatic start/stop, pressure monitoring, flow monitoring, and fault alarm functions. This ensures high reliability even when the system is unattended. They can also be integrated into fire management platforms through remote monitoring systems, enabling rapid response and data tracking, thus improving the overall safety and management efficiency of the fire protection system. Ease of installation and maintenance is also a significant advantage of this type of pump. The pump body and motor utilize a standardized coupling structure, eliminating the need for complete disassembly during maintenance. Turning, alignment, and inspection of the mechanical seal are all very convenient. The base has pre-drilled mounting holes to accommodate various engineering installation needs, allowing for quick matching in both new and retrofit projects. The simplified internal structure design reduces component wear, making daily maintenance more efficient, reducing downtime and maintenance costs. The system also provides detailed maintenance guidelines and cycle recommendations, enabling users to easily manage equipment performance and lifespan, ensuring the pump is always in optimal condition. In terms of application scenarios, this type of pump performs exceptionally well in harsh environments such as industrial fire protection systems, ships and docks, chemical industrial parks, warehousing and logistics centers, energy and power facilities, airports and transportation hubs, mining areas and tunnels, and outdoor construction sites. It maintains high efficiency, especially in areas with significant temperature differences, such as extremely cold or hot environments. In humid or salt-spray-prone coastal areas, its corrosion-resistant design extends its service life and reduces maintenance costs compared to ordinary fire pumps. Furthermore, in environments with high dust, strong vibration, or corrosive gases, enhanced sealing design and reinforced structures can significantly improve the stability and reliability of the system, ensuring that the fire protection system will not fail in emergencies. Overall, the heavy-duty fire pump system solution suitable for harsh environments is a high-standard device that has been upgraded and optimized in terms of structure, materials, power, performance, and installation and maintenance. It can meet the long-term stable operation requirements of various demanding scenarios, providing high-flow, high-head, and highly reliable fire water supply. This not only improves system safety but also reduces overall maintenance costs, extends equipment lifespan, and helps engineering projects maintain complete fire protection capabilities in various complex environments. It is one of the indispensable core devices in modern buildings, industrial projects, and fire protection engineering in special environments.

.jpg)