Diesel engine fire pump has been widely used in fire diversion

The biggest difference between a diesel engine fire pump and an electric water pump is that it has its own independent power supply system, which ensures the normal operation of the project without power or power supply. Its role is self-evident, and it can be said to be a great helper in fire emergency .

In terms of industrial applications, diesel engine fire pumps are widely used in emergency water supply for large-scale projects such as high-rise buildings, steel plants, chemical plants, hotels, and water works.

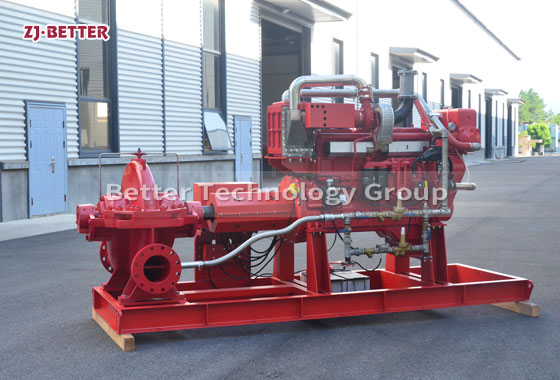

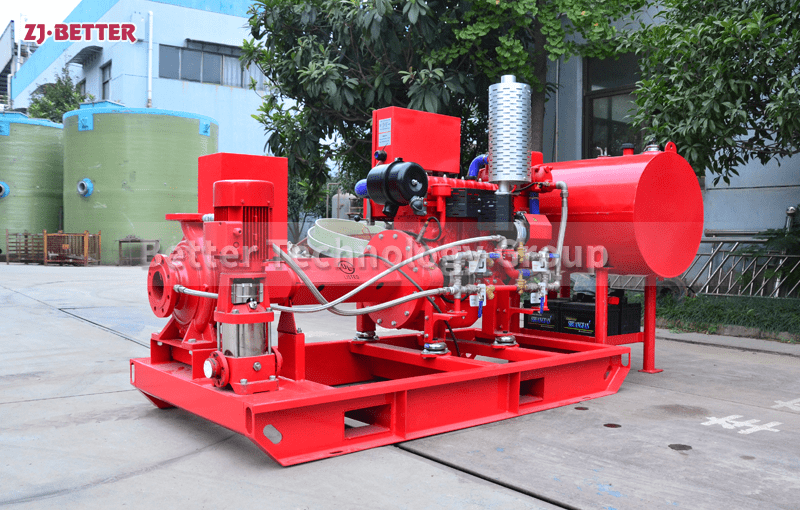

Diesel engine fire pump, as a fixed fire extinguishing equipment, has been widely used in fire diversion, especially in the case of sudden fire water supply such as insufficient or abnormal power supply, the fire pump equipped with this unit is a horizontal single-stage , Multi-stage special fire pump, mainly composed of diesel engine, fire pump, connection device, fuel tank, etc. Diesel engine fire pump products such as radiator, battery pack, intelligent automatic control panel have leading technology, high degree of automation, excellent performance protection function and reasonable structure , Simple installation, high cost performance and so on. At the same time, in order to meet the different needs of users and make reasonable investment, the products are divided into application series such as fire pumps, industrial emergency pumps, agricultural pumps, marine pumps, and trailer mobile pump stations, which can be used in conjunction with electric fire pumps.