Round-the-Clock Safety: Diesel Fire Pump Units for Complex Working Conditions

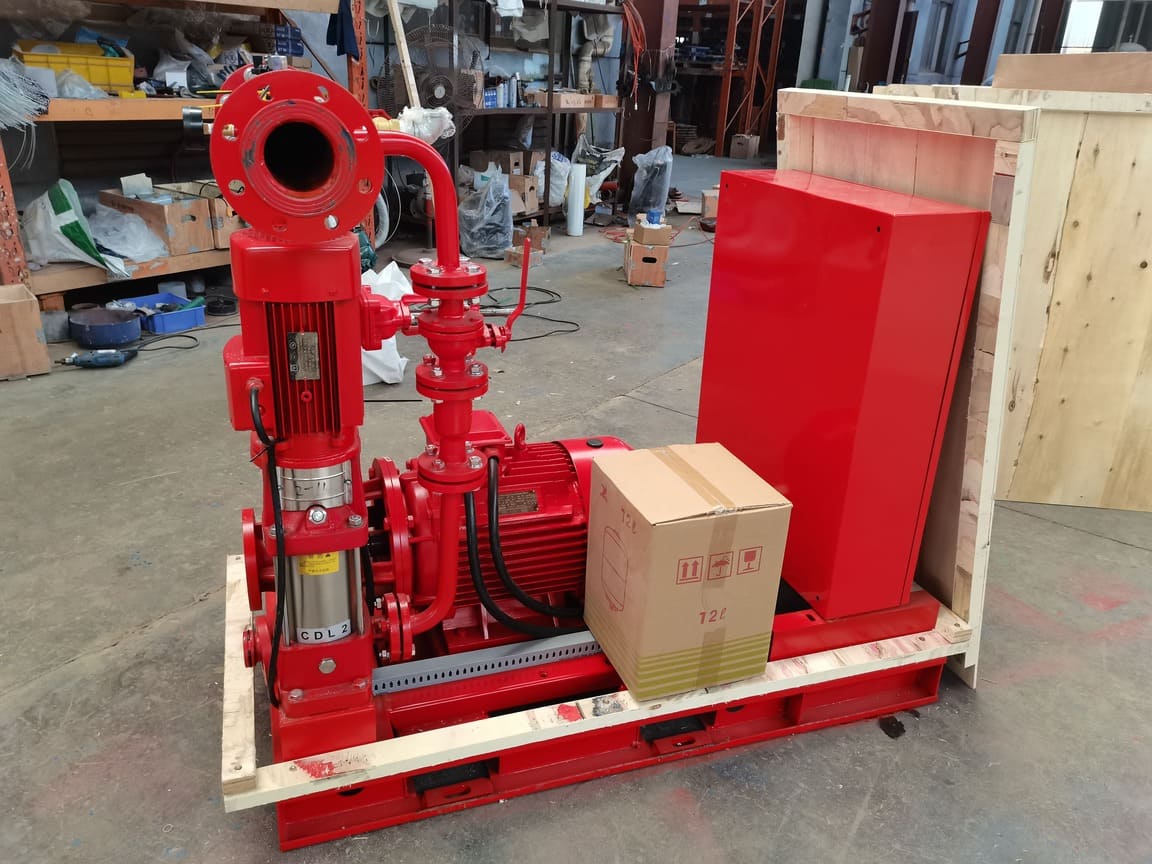

This diesel engine fire pump set is engineered to perform in challenging and unpredictable environments. Completely independent of the power grid, it delivers exceptional operational reliability, ensuring continuous water supply in critical moments. Powered by a world-class diesel engine, it features rapid start-up, robust torque, and consistent performance during power outages, extreme weather, or emergencies—making it ideal for mines, chemical plants, airports, and high-rise buildings.

The unit comes equipped with an intelligent control panel offering automatic start/stop, fault alarms, and real-time monitoring for simplified operation and easy maintenance. Its compact design allows it to fit into space-constrained installations. Whether in high-temperature, high-humidity, or freezing conditions, this diesel fire pump system delivers stable and efficient performance—an ideal solution for industrial-grade fire protection.

Specializing in the research, development, and manufacturing of fire protection system solutions, this company offers a diverse product portfolio that includes diesel fire pump sets, electric pump units, control panels, and pressure stabilization systems. With a complete quality management system and a professional technical team, all products are manufactured to meet international standards and are widely used across industrial, commercial, civil, and municipal sectors. Through continuous innovation and enhanced service capabilities, the company is committed to advancing fire safety standards worldwide.

管道泵(不锈钢304316L).jpg)