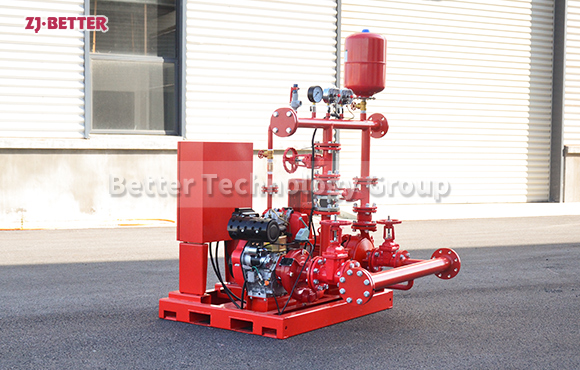

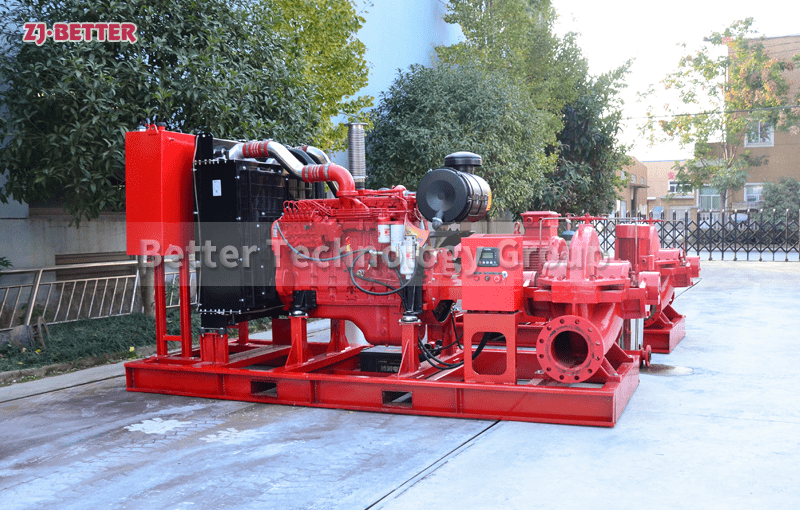

Stable Horizontal Fire Pump Solution Designed for Continuous Heavy-Duty Operation

High-performance horizontal fire pumps are designed for fire protection systems in industrial plants, warehouses, logistics facilities, and high-rise buildings. They feature stable flow and head output, robust structure, reliable operation, and convenient maintenance. They are suitable for long-term standby and high-load fire water supply applications, ensuring rapid start-up and continuous and stable water supply in critical moments.

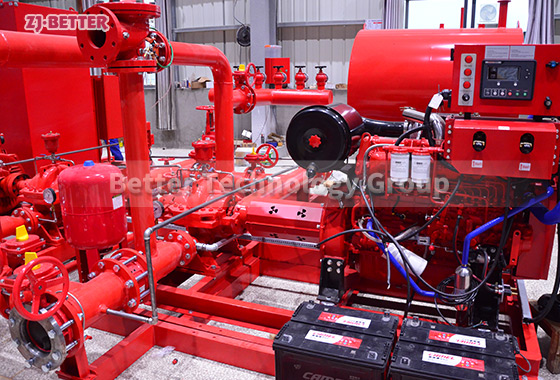

This product is a horizontal fire pump solution designed with stability and reliability as its core objectives. It is specifically developed for fire water supply systems requiring long-term continuous operation and high load conditions. The overall structure adopts a mature and reliable horizontal layout, ensuring convenient installation and maintenance while effectively reducing equipment vibration and noise levels. It is particularly suitable for large industrial plants, logistics and warehousing centers, high-rise buildings, commercial complexes, municipal infrastructure, and key protected locations with extremely high reliability requirements for fire protection systems. In terms of hydraulic design, this fire pump fully considers the balance between high flow rate and stable head. By optimizing the impeller hydraulic model and flow channel structure, the water flow inside the pump body is smoother, reducing eddies and energy losses. This allows it to maintain stable output under different operating conditions. Even in the event of sudden start-up of the fire protection system or large pressure fluctuations, it can quickly establish rated pressure, ensuring that fire water is available immediately. In terms of structural design, this product adopts a high-strength pump body and a rigid shaft system. Key load-bearing components are made of high-quality materials and undergo rigorous processing and heat treatment, giving the entire unit excellent fatigue resistance and wear resistance, enabling it to withstand harsh operating environments with frequent start-stop cycles and long-term uninterrupted operation. Addressing the characteristics of fire pumps requiring long-term standby and reliable startup in critical moments, this product features enhanced sealing and bearing systems. A rationally configured mechanical seal or packing seal structure effectively reduces leakage risk. High-load-bearing capacity bearings and a stable lubrication method significantly extend service life and reduce maintenance frequency. The matching between the motor and pump body has been precisely calculated and repeatedly verified to ensure high operating efficiency and low energy consumption under rated conditions, meeting fire safety regulations while helping to reduce overall system operating costs. This fire pump exhibits excellent compatibility in control and integration, flexibly connecting to various fire control systems. It can be used in conjunction with pressure sensors, flow monitoring devices, and automatic start-stop control units to achieve intelligent management and stable operation of the fire protection system. Even in complex environments with high temperatures, humidity, or dust, the equipment maintains excellent working condition, demonstrating the reliable quality expected of an industrial-grade product. From an installation perspective, the horizontal structure lowers the center of gravity, resulting in more stable operation and less demanding foundation requirements. This facilitates placement in pump rooms or integrated fire pump sets, reducing on-site construction difficulty and time. Before leaving the factory, the products undergo rigorous performance testing and quality inspection, covering multiple key indicators such as flow rate, head, efficiency, vibration, noise, and sealing performance, ensuring that each unit meets design requirements and operates stably for a long period after being put into use. Overall, this horizontal fire pump solution not only meets or exceeds the performance requirements of conventional fire protection systems, but also excels in stability, durability, and operational reliability. It is a professional fire water supply equipment meticulously designed for continuous high-load conditions, enabling users to build a safe, reliable, and efficient fire water supply system, providing trustworthy fire power support in critical moments.