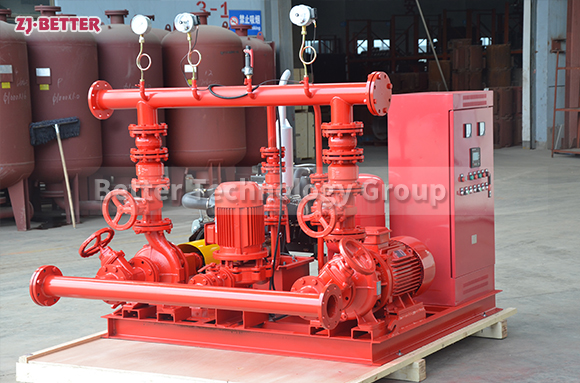

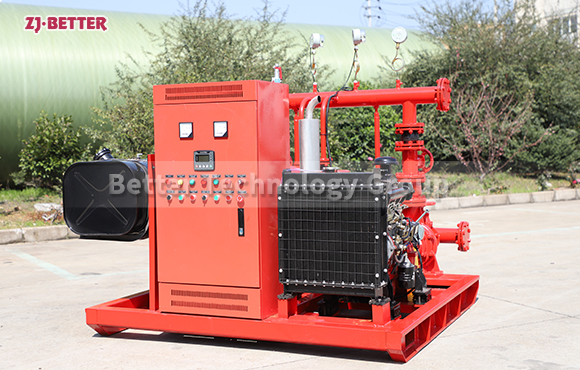

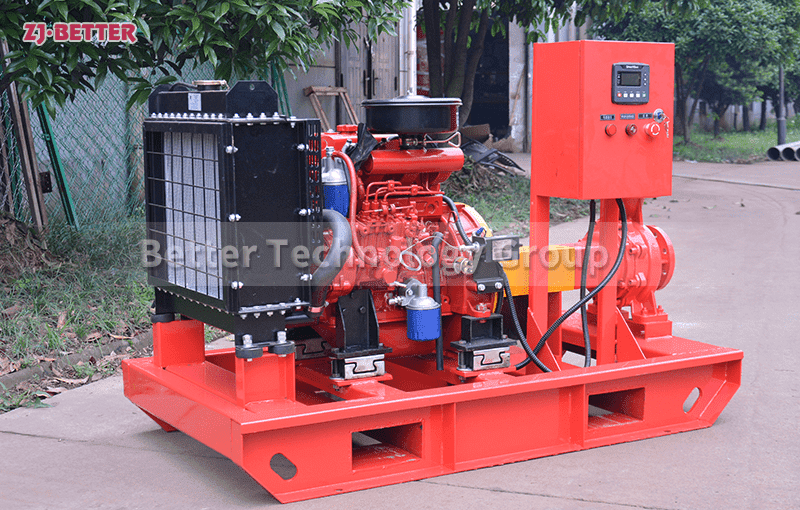

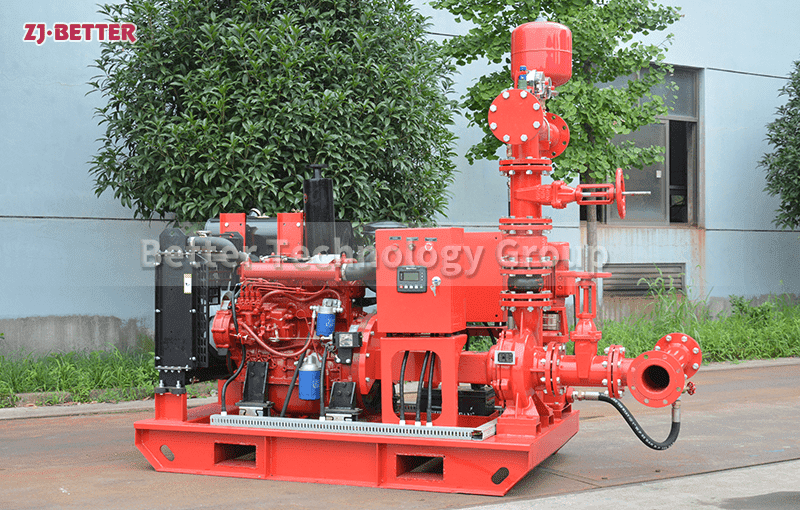

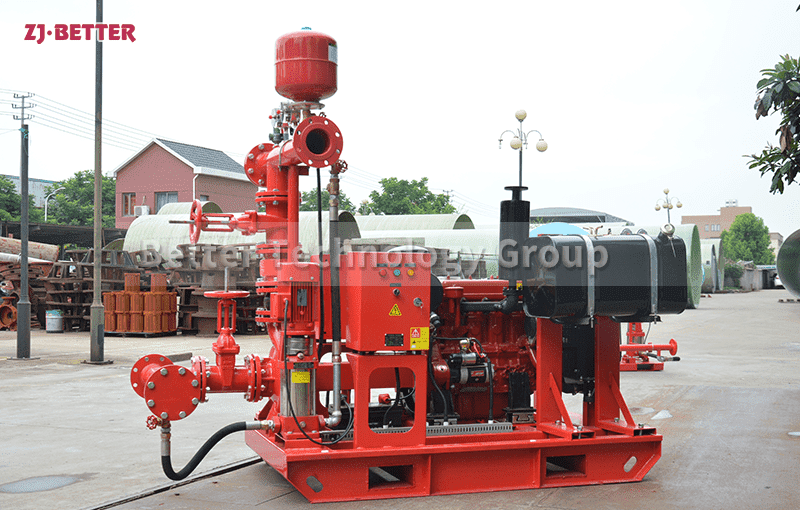

High Efficiency EDJ Fire Pump Set

It can run in the condition of power cut.

It can fully run in 15 seconds after the start signal.

Use Universal Joint, high transmission efficiency.

Good stability, vibration proof.

Motor pump is duty pump, diesel engine is for standby

Completely automatic control panel.

Suitable for any emergency firefighting occasions.

Customized product.

The main pump of the fire pump set can be end suction pump, multistage pump, split case pump,or vertical turbine pump with stainless steel, cast iron and bronze material in standard configurations.

Fire Pump Control Panel is the Pump System brain that designed to Control & Monitor the operation of the Electric, Diesel, and Jockey Pumps drivers, and makes up pumps for both Manual & Automatic modes, as well as turns pumps drivers ON/OFF under specific conditions.

The Fire Pump Package Controller detects signals through set of built in pressure switches that reflect the system pressure & flow status enabling fire pump package drivers (Electrical /Diesel /Jockey) to operate in case of pressure in the system is lower than set point, as well as operating the Standby driver due to power failure and/or substantial drop in pressure.

Fire Pumps Series Controllers are pre-wired, tested before delivery and made ready for immediate usage.

The electric pump is coupled with YE3 high efficient motor with protection IP55 class F, anti-corrosive coating pump case, quality NSK bearings, and wear resistance mechanical seal. Cast iron, brass and stainless steel impellers are all available.

This fire pump set can be used for fire hose and fire hose reel system, fire sprinkler system, fire water monitor system, fire alarm system and fire hydrant system.