How Diesel-Driven Fire Pumps Ensure Continuous Water Supply During Fires

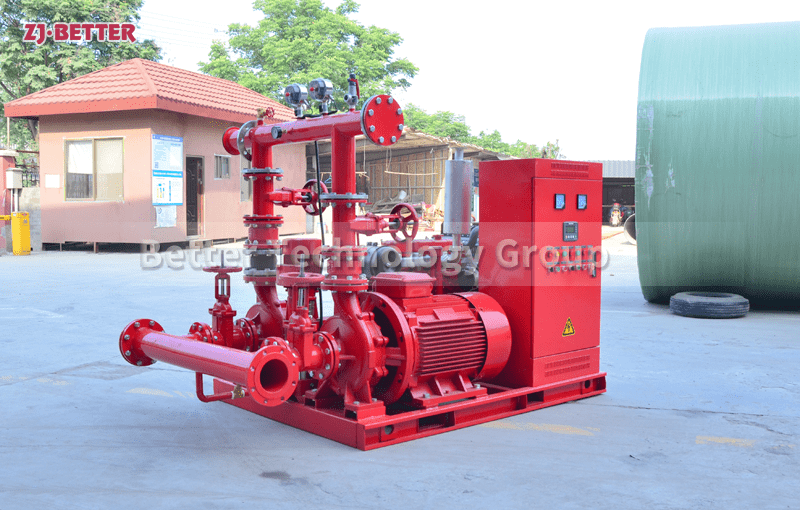

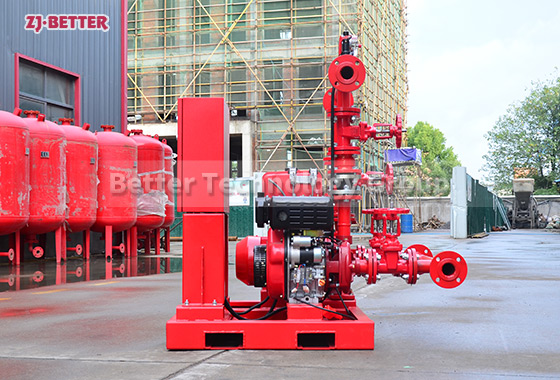

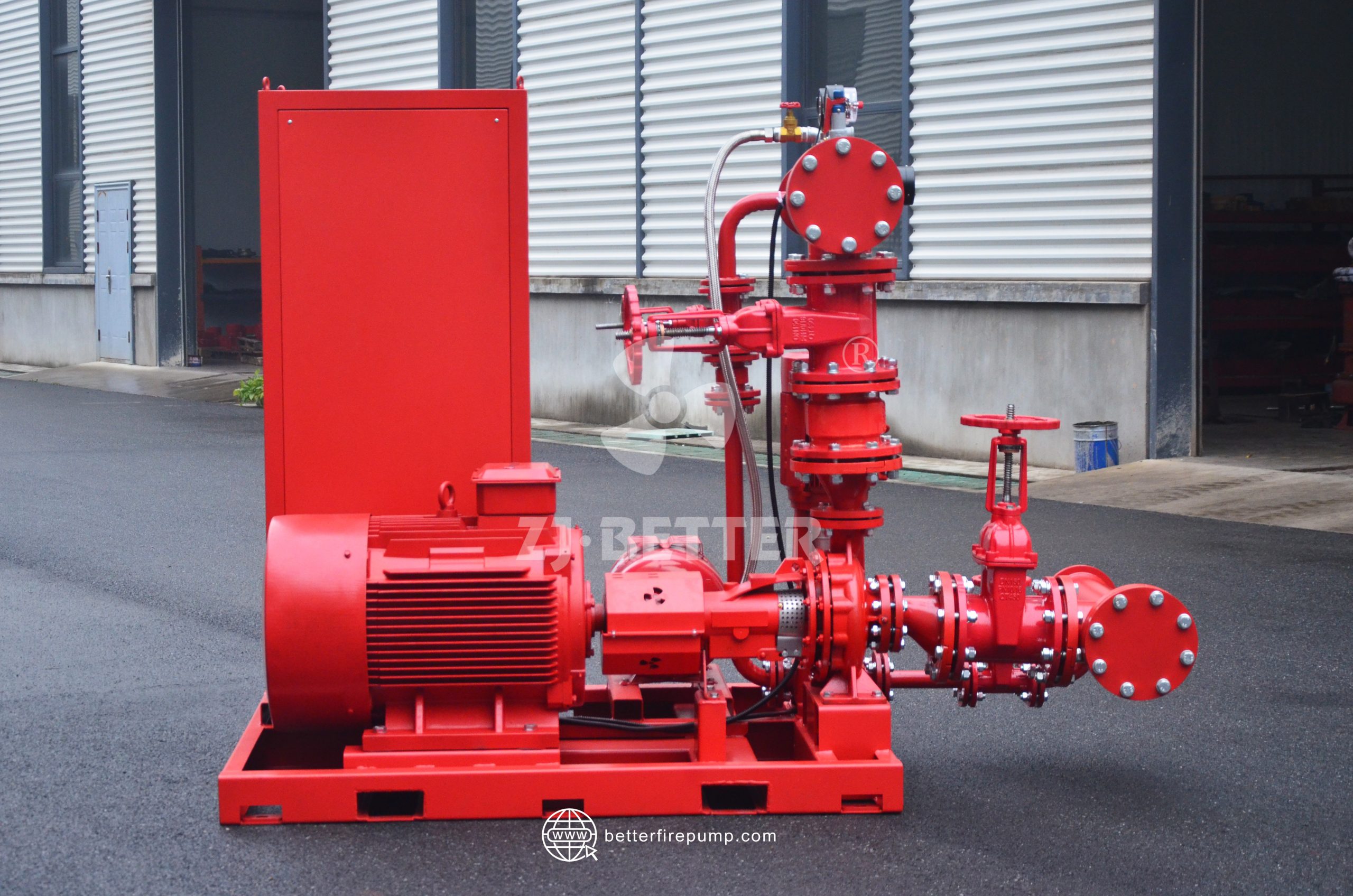

Diesel engine-driven fire pumps have the advantages of independent power, efficient water supply, durability and stability, and intelligent control. They can still operate reliably in power outages and are widely used in high-rise buildings, petrochemicals, power plants, and large industrial sites, providing a continuous and safe high-pressure water source for fire protection systems.

Diesel-engine-driven fire pumps, a crucial water supply component in modern firefighting systems, are characterized by their ability to maintain stable operation even in power outages, ensuring a continuous water supply during firefighting operations. This is particularly important in high-risk areas such as high-rise buildings, large commercial complexes, industrial plants, warehouses and logistics centers, petrochemical sites, and power facilities. These pumps, powered by a diesel engine, drive a centrifugal pump via a direct or flexible coupling, providing high-pressure, high-flow water supply. They offer high reliability, robust independence, and a wide range of applications, meeting the stringent firefighting water supply requirements of various locations. One of the key advantages of diesel-engine-driven fire pumps is their independent power supply. During a fire, a building may experience power outages or system damage, rendering electric fire pumps inoperable. However, diesel-engine fire pumps, driven by internal combustion, are independent of the external power grid, ensuring a sufficient supply of water for firefighting even under these extreme conditions. This feature significantly enhances the safety and redundancy of firefighting systems, ensuring independent operation even in the event of a complete power failure, thus avoiding the costly downtime that can result from firefighting. In terms of performance, diesel-powered fire pumps cover a wide range of flow rates and lifts, allowing for flexible configuration to suit different usage scenarios. They can achieve both high-flow, continuous water supply and the pressure requirements of high-lift structures. These pumps generally feature an optimized fluid dynamics structure, with smooth, unobstructed flow passages, ensuring high hydraulic efficiency. The high-performance diesel engine boasts high fuel efficiency and stable power output, coupled with high-strength couplings for efficient transmission, ensuring the entire system maintains energy efficiency and stability over extended periods of operation. In addition to water supply performance, diesel fire pumps also excel in durability and stability. The pump body is typically constructed of high-strength cast iron or alloy steel, offering corrosion resistance, high temperature resistance, and wear resistance, ensuring it can withstand the impact of high-pressure water flow and complex environments. The diesel engine is equipped with a comprehensive cooling and lubrication system to ensure proper operation even during extended periods of operation and in high-temperature environments, preventing performance degradation due to overheating. The units are typically mounted on a reinforced base with a vibration-damping design, effectively controlling noise and vibration during operation. This not only extends the equipment lifespan but also ensures a comfortable operating environment. In terms of control and automation, diesel-engine-driven fire pumps widely utilize intelligent control technology, offering multiple modes such as automatic start, manual start, and remote monitoring. Upon receiving a signal from the fire alarm system, the diesel engine quickly starts and drives the pump within seconds, generating high-pressure water supply. Simultaneously, the control system monitors key parameters such as the unit’s speed, pressure, flow rate, oil temperature, and water temperature in real time, issuing alarms when anomalies occur and automatically shutting down the unit as necessary to prevent damage caused by malfunctions. Some units also support integration with building fire protection systems for centralized monitoring and unified dispatch, significantly improving operational convenience and safety. Diesel-engine-driven fire pumps are also relatively easy to maintain and service. They are often designed with easy disassembly and assembly features, with reserved access for maintenance. Routine filter changes, oil changes, belt adjustments, and pump overhauls can be completed quickly. In addition, the system is equipped with an automatic rechargeable battery, ensuring it can be started at any time even in standby mode, preventing startup failures due to battery depletion. The fuel tank is designed with ample capacity, allowing for over eight hours of continuous fuel supply as needed, ensuring no downtime during prolonged firefighting missions. Compared to electric fire pumps, diesel-powered fire pumps offer significantly greater emergency adaptability and are particularly suitable for use in areas with unstable power supply, outdoor facilities, or locations remote from the municipal power grid. For performance redundancy, many facilities often use diesel fire pumps as backup pumps, forming a dual-power firefighting system alongside electric pumps. If the electric pump becomes unavailable due to power outage or failure, the diesel pump can immediately take over, ensuring system continuity and reliability, thus meeting the requirements of international standards such as NFPA, UL, and FM. Diesel-powered fire pumps are not only used in sprinkler and fire hydrant systems in high-rise buildings, but are also widely used in petrochemical, airport and port operations, mining, metallurgy, power generation, papermaking, and large-scale warehousing and logistics, where fire protection requirements are extremely stringent. These locations often require high-flow, long-term water supply, and diesel pumps, thanks to their independent drive, continuous stability, and high reliability, are the preferred equipment. In some specialized industries, diesel pumps can also be paired with foam and spray systems to create a more efficient, comprehensive firefighting solution. In terms of cost-effectiveness, diesel-powered fire pumps offer a good balance between overall service life and operating costs. While the initial investment is slightly higher than that of a single electric pump, their high efficiency and stability mean lower maintenance costs over time and avoid the significant losses caused by water supply interruptions during fires, resulting in an extremely high overall return on investment. Furthermore, fuel costs can be optimized through the efficient diesel engine and energy-saving design, ensuring users achieve the optimal balance between safety and cost. Overall, diesel-powered fire pumps, with their independent and reliable power source, superior water supply performance, exceptional durability and stability, intelligent control systems, and wide application adaptability, have become an indispensable core component of modern firefighting systems. Whether in high-rise buildings, industrial facilities, or in power-scarce or remote areas, it can provide continuous water source support for firefighting and rescue at critical moments with its powerful performance and reliable protection, minimize the losses caused by fire, and demonstrate irreplaceable value.