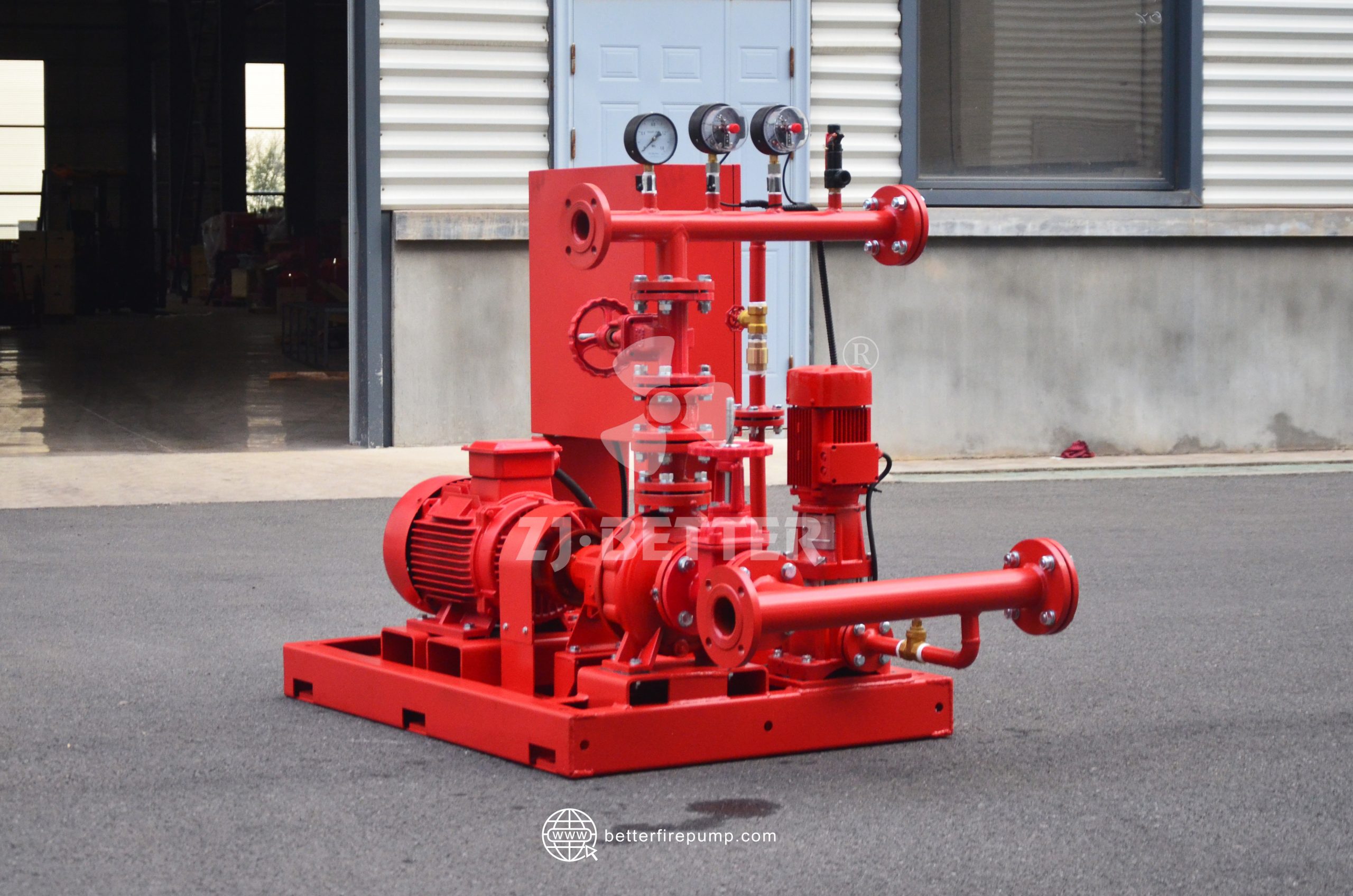

Components of Fire Jockey Pump Set

Flow: 5-400L/s

Head: 3-20Bar

Material:

HT200, SS304, Bronze

Caliber:65-350mm

Pressure: 0.3~1.5MPa

Speed:740-2900r/min

Components :

Electric pump: kinds of end suction pump, split case pump, multistage pump. made of cast iron, stainless steel. Impeller can be bronze.

5.5-710 kw 0.3-1.2 mpa 10-420 l/s (100-6600GPM)

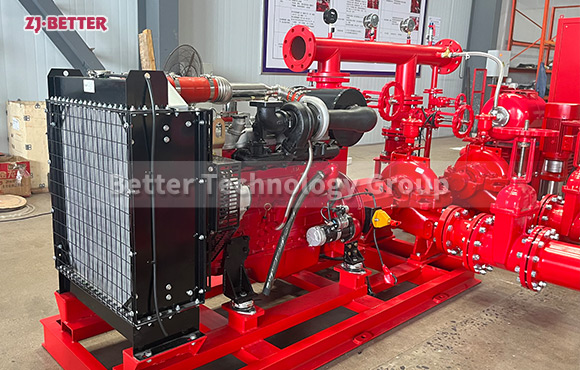

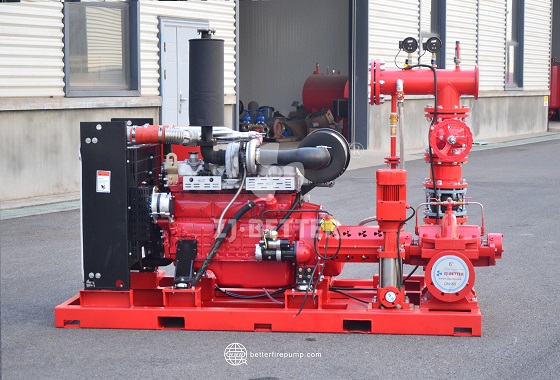

Diesel pump: Flow is the same with electric pump. It connects the pump set with High elastic coupling or universal joint. It also includes water tank, oil tank, fans, control screen etc.

7.0-810 kw 0.3-1.2 mpa 10-420 l/s (100-6600GPM)

Jockey pump: horizontal or vertical, small flow, head is higher than electric or diesel pump

0.75-4kw 0.45-1.36 mpa 2-4 m3/h

Control panel: control the pumps automatically with overload, overcurrent protection

Accessories: check valve, gate valve, pressure tank (0.6mpa, 1.0mpa, 1.6mpa) Pressure gauge, pressure sensors, import and export common pipe, soft joints, flanges and common base.

According to flow, the fire pump package is divided into two types: small flow (30GPM ~ 100GPM) and large flow (120GPM ~ 5000GPM). Generally, the small flow Fire pump package does not have a jockey pump set (motor pump set + engine pump set), large flow dual power have jockey pump unit (motor pump set + engine pump set + jockey pump set).