Continuous Operation with Low Maintenance: Long-Term Performance of Industrial Electric Fire Pumps

High-efficiency electric fire pumps are renowned for their stable performance, low energy consumption, and intelligent control systems, and are widely used in high-rise buildings, industrial facilities, and emergency fire water supply systems. Their high-lift design, corrosion-resistant materials, and automated control ensure long-term reliable operation, providing a continuous and safe water supply for various fire protection systems.

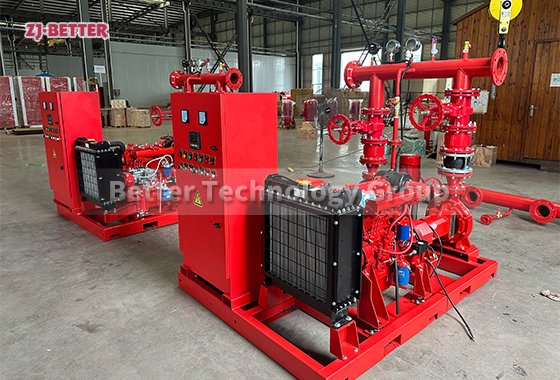

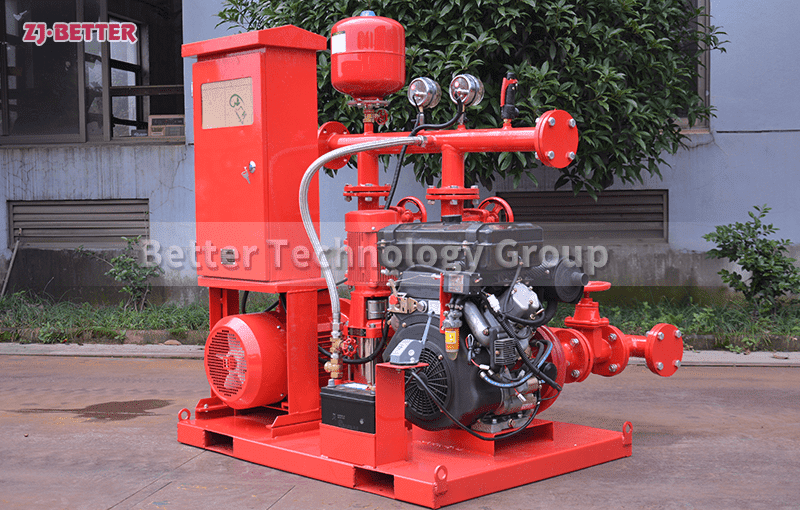

Electric fire pumps, as one of the core power devices in modern fire protection systems, play a vital role in fire water supply systems for industrial facilities, high-rise buildings, warehousing bases, chemical plants, and public infrastructure. Industrial-grade electric fire pumps, renowned for their high efficiency, energy saving, stable operation, and convenient maintenance, are an ideal choice for ensuring fire safety and reliable water supply due to their continuous operation capability and low maintenance costs. These fire pumps are typically manufactured using high-strength alloy materials and precision machining processes, enabling them to operate for extended periods under high pressure, high temperature, and complex conditions, ensuring rapid startup and a stable high-lift water flow output in any emergency fire situation. One of the biggest advantages of electric fire pumps lies in the high energy efficiency brought about by their motor drive. Compared to traditional diesel or gasoline drive systems, electric motors offer stable speed, low energy consumption, and low noise. High-efficiency motors can convert electrical energy into mechanical energy at an efficiency of over 90%, greatly reducing energy waste while avoiding fuel consumption and exhaust emissions, making them more environmentally friendly. This green and energy-saving characteristic not only aligns with the sustainable development concept of modern buildings but also significantly reduces operating costs over long-term use. Its electrical control system typically employs an intelligent design, featuring multiple functions such as automatic start-up, pressure detection, flow regulation, remote monitoring, and fault alarms. It can respond instantly after a fire alarm system is triggered, automatically completing start-up and shutdown operations without manual intervention, significantly improving emergency response efficiency. Industrial-grade electric fire pumps utilize a high-lift, multi-stage centrifugal design, achieving high-pressure output through multiple impellers connected in series. The internal flow channels of the pump body are optimized for fluid dynamics, minimizing water flow resistance and significantly improving efficiency. Its impellers and guide vanes are typically made of wear-resistant cast iron or stainless steel, possessing excellent corrosion resistance and wear resistance, suitable for conveying clean water, mildly corrosive liquids, or media containing small amounts of impurities. A high-precision mechanical seal design effectively prevents leakage, extending equipment life and reducing maintenance frequency. To ensure long-term continuous operation stability, the electric fire pump’s bearing system uses high-quality rolling bearings and a lubrication and cooling structure, capable of withstanding thermal stress and vibration under prolonged high-load operating conditions. The motor and pump body employ a coaxial direct-drive structure, reducing transmission losses, improving transmission efficiency, and simultaneously reducing mechanical noise and vibration, thereby enhancing overall operational stability and service life. Furthermore, this structure simplifies the installation and alignment process, making on-site maintenance more convenient and further reducing operating costs. Industrial electric fire pumps not only excel in technical parameters but also undergo rigorous verification in reliability and safety. Each pump undergoes performance testing before leaving the factory, including tests for flow rate, head, efficiency, vibration, noise, and insulation strength, to ensure it meets national and international fire protection standards. During operation, it can maintain a constant pressure output for extended periods, ensuring stable system pressure whether operating alone or in parallel, meeting the complex needs of multi-point water supply in high-rise buildings or large industrial facilities. Compared to traditional fire pumps, the electric drive system offers more precise control and a more sensitive response, making it particularly suitable for emergency environments requiring rapid start-up and efficient water supply. Due to its fully enclosed design, the electric fire pump typically achieves an IP55 or higher protection rating, effectively preventing dust and water damage and adapting to various complex environments, including humid, dusty, and chemical gas environments. For areas with significant temperature variations, some models are equipped with automatic temperature compensation and overheat protection systems, automatically shutting down the pump when the motor temperature exceeds a set value to prevent burnout. For industrial applications requiring long-term operation, this pump can be equipped with a soft starter or a frequency converter control system. This avoids the high current surge during motor startup, reduces grid load, and allows for intelligent adjustment of pressure and flow through frequency converter control, improving system flexibility and saving significant energy. Electric fire pumps also offer significant advantages in installation and maintenance. Their compact design and small footprint make them suitable for installation in confined spaces such as pump rooms, basements, or equipment rooms. The modular structure of the motor and pump body facilitates disassembly and maintenance; routine maintenance only requires replacing easily worn parts such as mechanical seals or bearings, resulting in shorter maintenance cycles and lower costs. Unlike diesel-driven systems, electric fire pumps do not require regular refueling, filter replacement, or engine maintenance, significantly reducing long-term operating costs. In daily management, electric fire pumps can be integrated with building fire control systems, enabling remote status monitoring and data acquisition via communication modules. This allows for real-time monitoring of key parameters such as equipment operating status, pressure, flow rate, and motor temperature, facilitating timely system status assessment and prevention of potential malfunctions by maintenance personnel. Electric fire pumps have a wide range of applications, from sprinkler systems in high-rise buildings in cities to water supply in industrial areas, from fire-fighting water supply in warehousing and logistics parks to emergency systems in large factories—all rely on this highly efficient and reliable equipment. For scenarios requiring 24-hour standby and immediate fire response, electric fire pumps can start up and provide stable water supply in a short time, ensuring that the pressure in the fire pipeline network remains within a safe range. They can be used not only as main pumps but also combined with diesel fire pumps and pressure-stabilizing pumps to form complete fire pump systems. In the event of a main power outage, backup power can continue operation, further enhancing system redundancy and safety. In long-term operation, industrial electric fire pumps demonstrate remarkable economy and durability. Due to the high-precision CNC machining and dynamic balancing of their core components, the pump sets experience low vibration, minimal wear, and low energy consumption, maintaining high-performance output even after years of continuous use. This long-term reliability reduces equipment replacement frequency and downtime for maintenance, bringing significant return on investment to users. In conclusion, industrial-grade electric fire pumps, with their high efficiency, low energy consumption, stable operation, easy maintenance, and long service life, have become an indispensable power core for various fire protection systems. Its comprehensive advantages in safety, energy saving, environmental protection, and intelligence enable it not only to meet traditional fire protection standards but also to align with the requirements of modern industrial and urban buildings for efficient and safe water supply systems. Whether in daily operation or emergency rescue, electric fire pumps, with their powerful performance and reliable capabilities, safeguard the safety of every critical facility, providing solid support for fire protection in cities and industries.