Horizontal Multistage Fire Pump: Reliable Power Supply for High-Rise and Industrial Fire Protection Systems

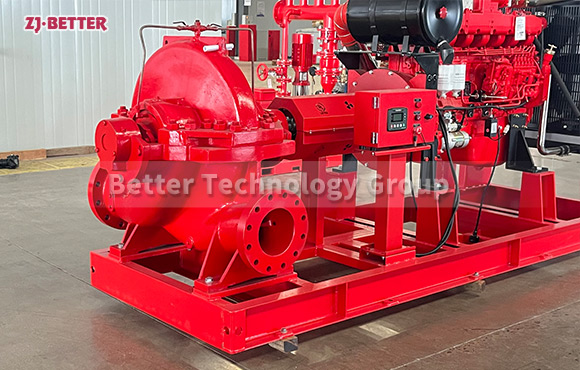

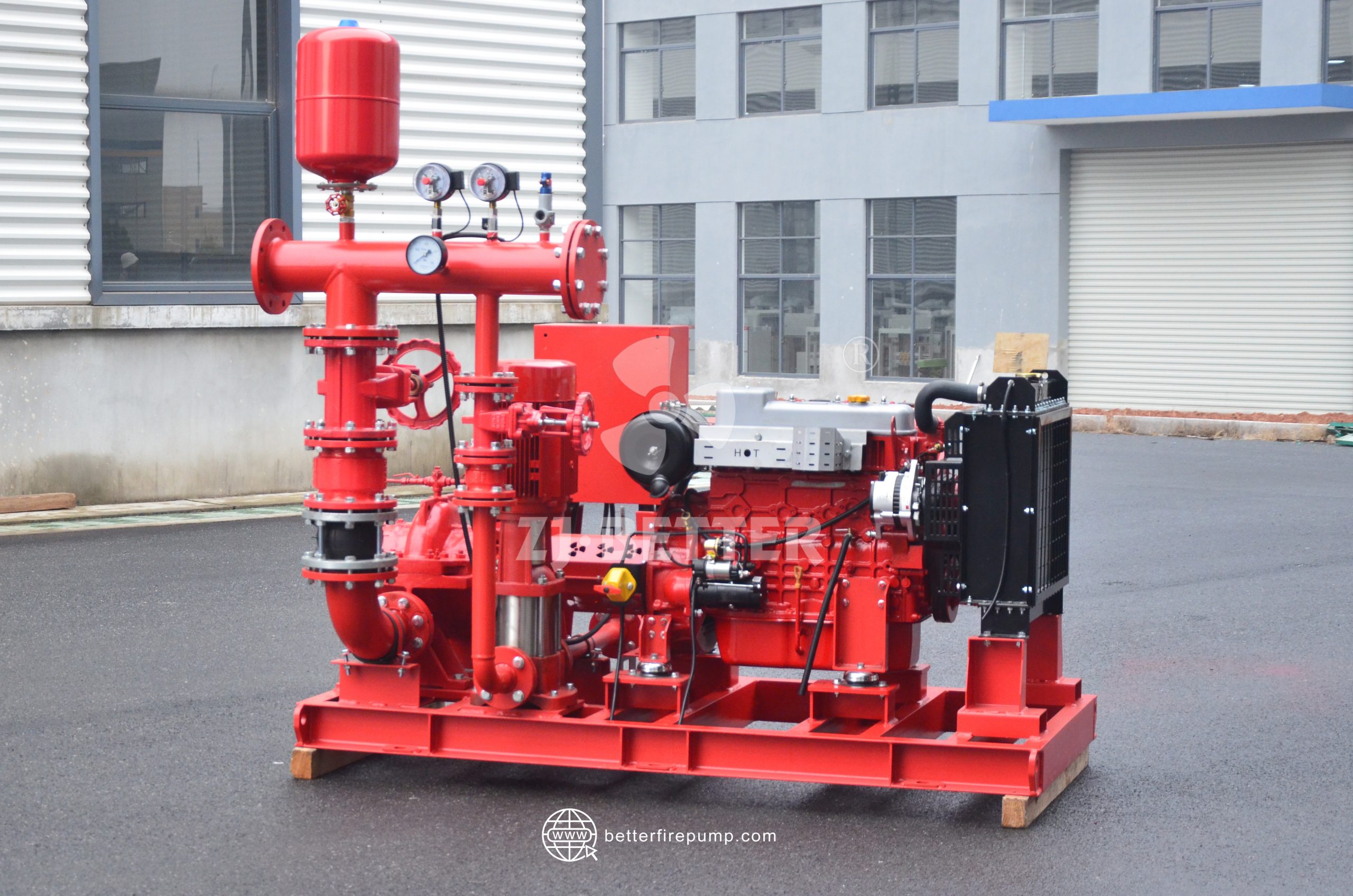

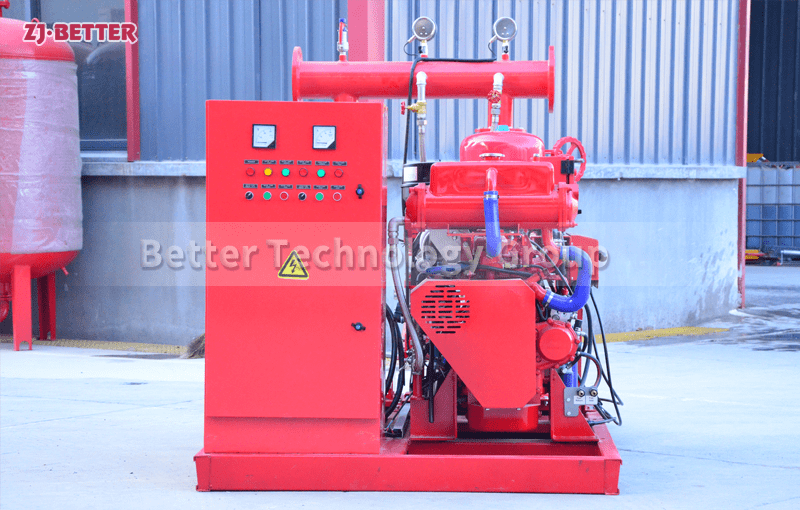

Horizontal multistage fire pumps are high-efficiency, stable, and high-lift fire water supply equipment, widely used in fire protection systems of high-rise buildings, factories, and infrastructure. These pumps feature compact structure, low energy consumption, stable operation, and easy maintenance. They provide strong water pressure and stable flow during fires, ensuring reliable operation of fire protection systems and making them an ideal choice for ensuring safe water supply.

Horizontal multistage fire pumps are high-performance fire-fighting water supply equipment specifically designed for high-rise buildings, industrial plants, commercial complexes, and large infrastructure projects. They play a crucial role in modern fire protection systems, providing strong water pressure and stable flow during fires to ensure rapid deployment of fire extinguishing systems in emergencies, effectively protecting lives and property. This type of pump, characterized by its compact structure, stable operation, high head, high efficiency, and high reliability, is widely used in various fixed fire protection systems, including sprinkler systems, fire hydrant systems, and foam extinguishing systems. The greatest advantage of horizontal multistage fire pumps lies in their multi-stage impeller series design, achieving high head output through multi-stage pressurization, easily meeting the high water pressure demands of high-rise buildings. Compared to single-stage pumps, multistage centrifugal pumps can output higher pressure within a relatively smaller volume, making the overall system layout more flexible and requiring less space, suitable for installation in equipment rooms or underground pump rooms. This structural design also results in smoother pump operation, less vibration, lower noise, and extended equipment lifespan. The pump body and cover are made of high-strength cast iron or ductile iron, possessing excellent corrosion resistance and mechanical strength. Even under long-term operation in humid or high-temperature environments, the structure remains stable and undeformed. The shaft seal employs a mechanical seal or packing seal structure, ensuring no leakage during long-term operation and improving system safety and environmental friendliness. The drive method is generally direct electric motor drive, with some models available with a diesel engine drive as a backup power source. This ensures a continuous supply of pressurized water during power outages or interruptions, significantly enhancing the reliability and emergency response capabilities of the fire protection system. The pump’s hydraulic design has undergone precise calculations and optimization, employing a high-efficiency closed impeller structure. The internal flow channels have been precisely polished and dynamically balanced, resulting in smoother liquid flow, reduced energy loss, and improved overall efficiency. The multi-stage impeller series design progressively increases liquid energy, ensuring stable flow output even under long-distance transport or high-lift water supply conditions, preventing pressure attenuation from affecting fire extinguishing effectiveness. Furthermore, horizontal multi-stage fire pumps offer exceptional adaptability in performance matching. Whether for small commercial buildings or large industrial parks, output parameters can be flexibly customized by adjusting the number of impellers, speed, or pump stages to meet the design requirements of different systems. This flexible configuration makes the product more versatile and economical in practical applications, allowing users to achieve optimal performance matching and energy consumption control according to specific working conditions. The motor uses a high-efficiency energy-saving motor with IP55 protection rating and F-class insulation performance, enabling continuous operation in harsh environments such as high temperature and high humidity. The motor and pump shaft are connected by a high-precision coupling, resulting in high transmission efficiency, low vibration, and easy disassembly and maintenance. To ensure stable system operation, the horizontal multi-stage fire pump is equipped with an intelligent control system, which can realize multiple functions such as automatic start/stop, pressure monitoring, flow regulation, and alarm prompts. Through signal linkage with the fire control center, automatic detection and fault diagnosis can be achieved. When the pipeline pressure drops to the set value, the system can automatically start the fire pump, and when the pressure recovers, it will automatically stop, thereby significantly improving the automation and intelligence level of the fire protection system. This control system typically includes manual, automatic, and remote control modes, which can be flexibly switched according to on-site needs. It meets both routine testing and maintenance requirements and ensures rapid deployment in emergency situations. The horizontal multistage fire pump exhibits excellent hydraulic performance and stability in performance tests. Its maximum flow rate can reach hundreds of cubic meters per hour, with a wide head range, from tens to hundreds of meters, covering various fire protection applications. Simultaneously, under full load operation, its efficiency can reach over 70%, with low energy consumption and stable output. The pump’s internal parts undergo rigorous dynamic balancing and wear-resistant treatment, and the bearings use high-quality rolling bearings or oil-lubricated structures to reduce friction loss and extend service life. The inlet and outlet flange design conforms to international standards, facilitating connection to piping systems while reducing installation complexity and maintenance costs. It is worth mentioning that the horizontal multistage fire pump can be used not only in fire protection systems but also in industrial water supply, boiler feedwater, air conditioning circulation, water treatment, and high-pressure cleaning, among other fields. Its superior high-head characteristics and stable output performance make it a versatile fluid transport device. For high-rise buildings, the pump set can supply water in layers, effectively overcoming pressure loss caused by gravity and ensuring sufficient pressure for fire sprinklers on each floor. For factories and warehouses, it can achieve rapid water supply and stable spraying, ensuring the reliability of the fire extinguishing system in critical moments. To meet the needs of complex environments, some horizontal multistage fire pumps are equipped with stainless steel impellers and corrosion-resistant shaft sleeves, which can be used to transport mildly corrosive media or clean water containing trace impurities. In addition, the pump body coating uses epoxy anti-corrosion material, which has good oxidation resistance and rust prevention performance, extending the service life of the equipment in harsh environments. The ease of maintenance of this pump set is also a major advantage. Due to the modular structural design, the impellers and guide vanes of each stage are assembled independently, allowing for maintenance and replacement without disassembling the entire pump, significantly saving maintenance time and costs. The lubrication system is simple and efficient, with low noise and low temperature rise during operation, maintaining high efficiency output even after long-term operation. In summary, the horizontal multistage fire pump is an advanced fire-fighting equipment that integrates high efficiency, stability, and safety. With its advantages of high head, high flow rate, energy saving, compact structure, and easy maintenance, the horizontal multistage fire pump occupies an important position in modern fire protection systems and is an indispensable core equipment for fire water supply in high-rise buildings, industrial facilities, and public infrastructure. Whether under continuous high-intensity operation or emergency start-up and shutdown conditions, the horizontal multistage fire pump can reliably ensure system safety, guaranteeing sufficient water supply support in any fire situation and providing a solid backing for fire safety.