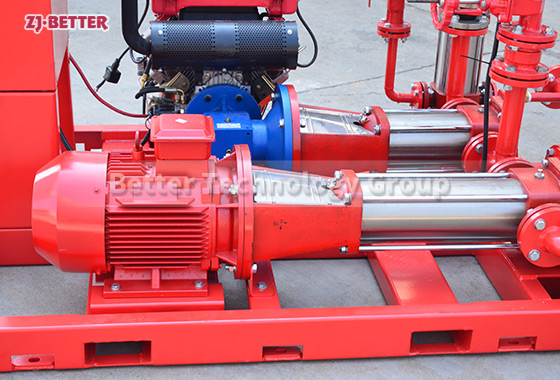

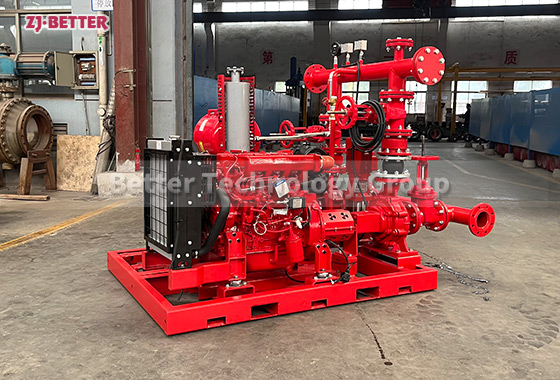

Stainless Steel Fire Pressure Water Supply Unit for Multiple Operating Conditions

The multi-condition stainless steel fire-fighting pressure-stabilizing water supply unit integrates multiple pumps in parallel, a pressure stabilizing tank, and an intelligent control system. It can stably regulate the pipeline pressure under different water use conditions and is suitable for building and industrial fire protection systems, effectively improving the reliability, stability, and service life of fire-fighting water supply.

This multi-condition stainless steel fire-fighting pressure-stabilizing water supply unit is a complete water supply system designed specifically for complex building fire protection systems and high-standard fire protection engineering needs. The overall solution revolves around three core objectives: long-term stable standby, adaptive adjustment under operating conditions, and reliable water supply in critical moments. Through deep integration of vertical fire pumps, multi-pump parallel systems, stainless steel pressure-stabilizing tanks, and intelligent control systems, it achieves pressure stability and water supply guarantee for the fire protection network at different operating stages. The unit uses stainless steel as the core pressure-bearing and water-transporting structure. The pressure-stabilizing tank and main pipelines are all made of corrosion-resistant stainless steel, effectively resisting the corrosion risks caused by long-term static water storage, changes in air humidity, and complex water quality conditions. This avoids the problems of rust, scaling, and leakage that occur in traditional carbon steel systems during long-term use, improving the reliability and service life of the fire-fighting water supply system from the source. The smooth inner wall of the stainless steel reduces hydraulic resistance, which helps reduce energy loss and improves the overall operating efficiency of the equipment while ensuring stable pressure in the fire protection system. The unit employs a design concept of multiple vertical pumps operating in parallel. Different pump sets can be started and stopped in stages according to actual system pressure changes and water demand. During normal standby and low-flow pressurization conditions, only a small number of pump sets operate, ensuring stable pipeline pressure and avoiding the mechanical shock and energy waste caused by frequent starts of the high-power main pump. When the system pressure drops significantly or enters a high-demand condition, the remaining pump sets can quickly be put into operation, forming sufficient water supply capacity to meet the simultaneous water demand of multiple points such as sprinkler systems and fire hydrant systems. This multi-condition adaptive operation mode ensures that the fire water supply system remains efficient, stable, and reliable at different stages. The vertical pump structure plays a significant role in this unit. The vertically arranged pump shaft occupies a small area, making it particularly suitable for building projects with limited equipment room space. At the same time, the vertical structure facilitates heat dissipation of the pump body and balance of bearing forces, resulting in less operating vibration, lower noise, and higher stability during long-term continuous operation. The pump’s hydraulic model has been optimized to maintain good efficiency curves under both rated and off-peak operating conditions, ensuring rapid start-up and quick pressure build-up, meeting the stringent requirements of fire protection systems for rapid response. The pressure stabilizing tank, a crucial component of the unit, plays a buffering and regulating role during system operation. Through reasonable volume design and pressure matching, it effectively absorbs instantaneous pressure fluctuations in the pipeline network, avoiding frequent start-ups and shutdowns caused by valve opening and closing or low-flow water usage, thereby further protecting the pump unit and pipeline system and extending their overall service life. The control system of this fire-fighting pressure-stabilizing water supply unit adopts a centralized intelligent control scheme. By monitoring key parameters such as pipeline pressure, pump operating status, motor current, and power supply status in real time, it achieves unified management of automatic control and safety protection. The system can automatically determine start-up and shutdown logic based on pressure signals, minimizing unnecessary operating losses while ensuring the fire protection system is always available. It also supports a manual control mode, facilitating manual intervention during commissioning, maintenance, or special operating conditions, enhancing system flexibility and safety redundancy. The control system also features comprehensive alarm and protection functions, promptly alerting administrators to abnormal operating conditions and helping them quickly pinpoint problems, reducing the impact of sudden malfunctions on the fire protection system. Addressing the characteristics of fire protection equipment—long periods of standby and occasional high-load operation—the unit strictly controls the quality of key components in material selection and manufacturing processes. Mature and reliable configurations are used for vulnerable parts such as shaft seals, bearings, and valves, ensuring good performance even under long-term static and periodic start-up conditions, reducing maintenance frequency and operating costs. The modular overall structural design allows for complete assembly and performance testing before leaving the factory, requiring only basic installation and piping connections on-site, significantly shortening the construction cycle and improving project delivery efficiency. This multi-condition stainless steel fire-fighting pressure-stabilizing water supply unit is suitable for various application scenarios such as high-rise residential buildings, commercial complexes, hospitals, schools, data centers, industrial plants, and large warehousing and logistics centers. It maintains stable operation under complex pipe network conditions and multiple water usage modes, providing continuous and reliable pressure and water supply support for the fire protection system. By organically combining corrosion-resistant stainless steel structure, multi-pump parallel operation mode, pressure stabilization and buffering technology and intelligent control system, this product demonstrates significant advantages in safety, stability, adaptability and long-term use value, and is an efficient water supply solution for modern fire protection engineering to meet the needs of multi-condition operation.