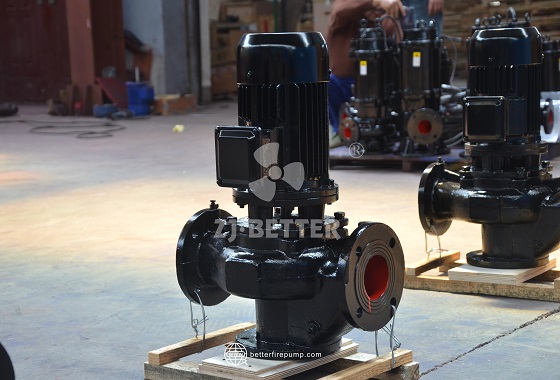

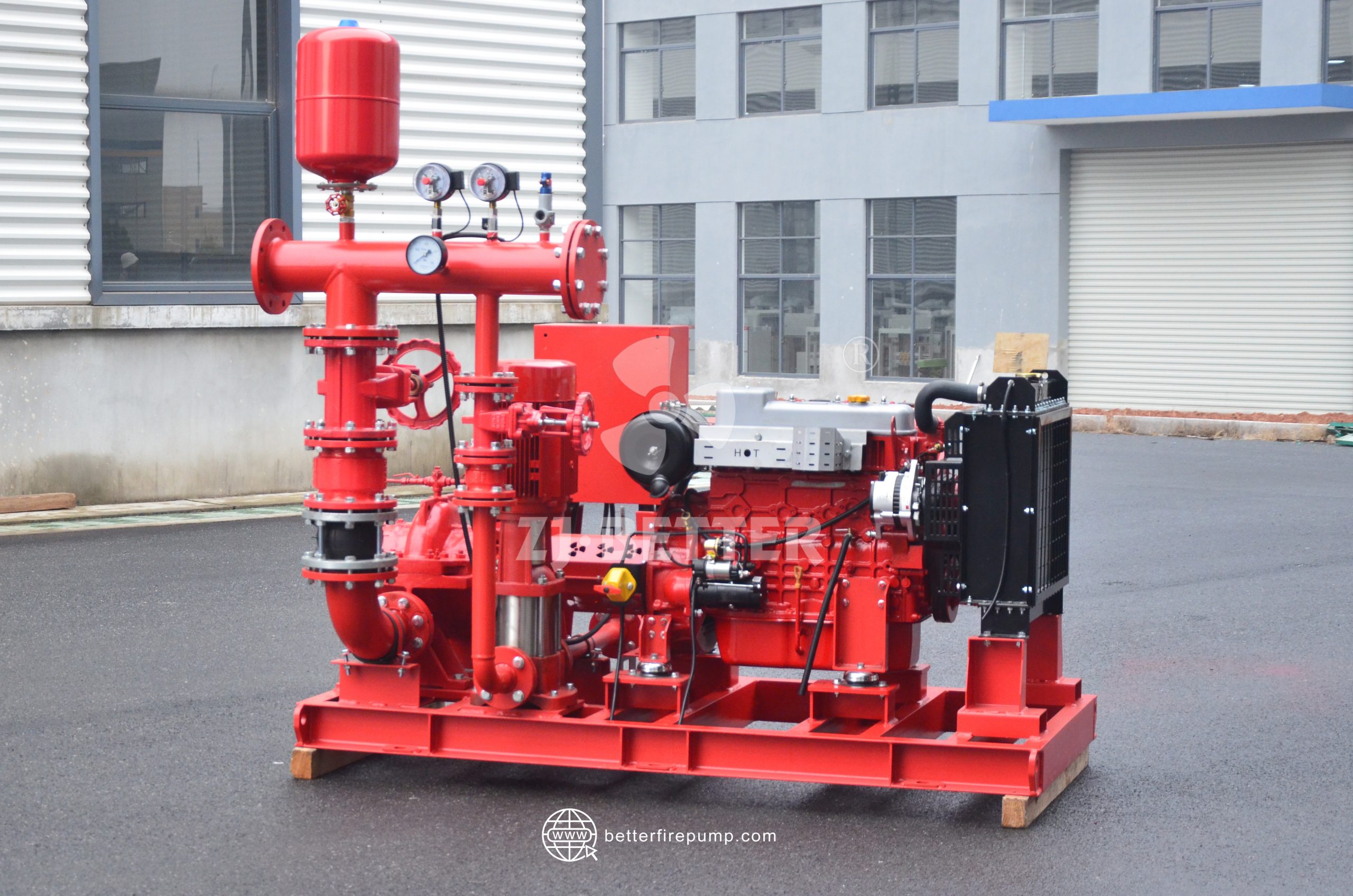

Integrated Vertical Fire Pump Water Supply System with Stainless Steel Piping

The integrated water supply solution for vertical fire pumps with stainless steel pipelines adopts a design of high-efficiency vertical pumps and corrosion-resistant stainless steel pipelines. It has advantages such as pressure stabilization and water replenishment, intelligent control and stable operation. It is suitable for building and industrial fire protection systems and comprehensively improves the safety, reliability and service life of fire water supply.

This integrated water supply solution using a stainless steel pipeline vertical fire pump is a highly reliable complete water supply system developed for modern building fire protection systems and demanding industrial fire protection environments. The overall design fully integrates the high hydraulic performance of a vertical fire pump, the durability and hygiene advantages of stainless steel pipelines, and the stable management capabilities of an intelligent control system. It can maintain a continuous, safe, and stable water supply under both long-term standby and emergency activation conditions. The core of this product is a vertical fire pump with a pump body flow channel that has undergone precise hydraulic calculations and optimized design, resulting in smooth internal water flow and minimal turbulence loss. It exhibits excellent efficiency within the rated flow and head range and maintains high operational stability even when deviating from design conditions, effectively avoiding pressure instability or insufficient water supply caused by fluctuations in operating conditions. The vertical structure allows for a vertically arranged pump shaft, minimizing floor space, making it particularly suitable for installation in space-constrained fire pump rooms or equipment rooms. It also facilitates neat pipeline layout and improves the overall aesthetics of the system. One of the significant advantages of this integrated water supply solution lies in the application of a full stainless steel piping system. All pipes and critical connections in contact with the medium are made of corrosion-resistant stainless steel, which not only effectively resists the risk of corrosion in long-term static water storage environments but also adapts to long-term use under different water quality conditions, significantly extending the service life of the entire fire-fighting water supply system. It also reduces the risk of leakage due to pipe aging and corrosion, ensuring a reliable water source for the fire-fighting system in critical moments. The smooth inner wall of the stainless steel pipes results in low hydraulic resistance, helping to maintain stable pressure and reduce pump energy consumption, achieving higher operating efficiency while meeting fire safety regulations. The solution adopts a highly integrated design, rationally integrating the vertical fire pump, stainless steel piping components, pressure stabilizing and water supply devices, valves, instruments, and control system onto a unified base or platform. The overall structure is compact and highly modular, facilitating factory pre-assembly and overall commissioning, as well as rapid on-site installation, significantly shortening the construction cycle and reducing the risk of human error during installation. The control system is a crucial component of this integrated water supply solution. Through an intelligent control cabinet, it centrally manages the system’s operational status, enabling automatic start/stop, automatic pressure regulation, operational status display, fault alarms, and multiple protection functions. This ensures that the fire pumps maintain stable system pressure during normal standby and can quickly respond and start operation in case of pipeline pressure drops or fires, preventing delays in fire water supply. The control logic fully considers the practical needs of fire protection systems for “high reliability and low malfunction,” supporting both manual and automatic operation modes. In automatic mode, the operating status is intelligently determined based on pressure signals; in manual mode, direct manual intervention is possible in emergencies, enhancing system safety redundancy. This stainless steel pipeline vertical fire pump integrated water supply solution excels in pressure stabilization performance. By rationally matching the operating ranges of the pressure-stabilizing pump and the main pump, the pressure-stabilizing system compensates for minor pressure leaks or water usage fluctuations in the pipeline network during normal operation, preventing frequent start/stop of the main fire pump. This effectively reduces equipment wear, extends the overall service life of the unit, and maintains the pipeline pressure within the required range. For high-rise buildings, commercial complexes, hospitals, data centers, and other locations with extremely high requirements for the continuity and stability of fire-fighting water supply, this solution can maintain good operating conditions under long-term standby conditions and quickly switch to high-load water supply status in the event of a fire, continuously providing stable flow and head to ensure the reliable operation of sprinkler and fire hydrant systems. The product is also well-designed for safety, with multiple protection measures in key components, including overload protection, phase loss protection, overvoltage and undervoltage protection, and abnormal status alarm functions, effectively preventing electrical or mechanical faults from affecting the equipment and fire protection system, thus improving the overall operational safety level. Ease of maintenance is also a significant advantage of this integrated water supply solution. The vertical structure and stainless steel piping layout are clearly defined, with ample maintenance space. Daily inspections and periodic maintenance are simple and intuitive, effectively reducing the workload and maintenance costs for operation and maintenance personnel. The entire system undergoes rigorous performance testing and operational verification before leaving the factory to ensure that flow, head, pressure stability, and control functions meet design requirements and can operate stably for a long period in actual engineering applications. In summary, this integrated water supply solution for vertical fire pumps with stainless steel pipelines, through the organic combination of efficient hydraulic design, corrosion-resistant pipeline system, intelligent control and highly integrated structure, not only meets the core requirements of various fire protection projects for safety, reliability and stability, but also shows significant advantages in saving space, reducing energy consumption and improving system management efficiency. It is an ideal choice for modern building and industrial fire water supply systems that balances performance and long-term value.