Electric fire pumps are used in a wide range of occasions

The electric fire pump unit is mainly used for fire hydrant fire extinguishing, automatic sprinkler fire extinguishing and other fire extinguishing systems of industrial and mining enterprises, engineering construction, high-rise buildings and other fixed fire extinguishing systems. It can be used to transport clear water without solid particles and media similar to water in chemical properties. It can also be used in common water supply systems for living and production, as well as construction, municipal water supply and drainage, etc.

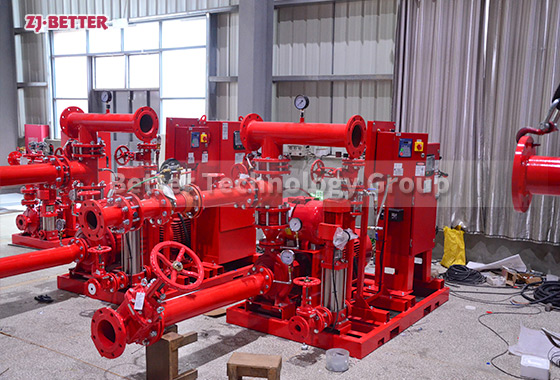

The electric fire pump unit complies with the national standard GB6245-1998 “Fire Pump Performance Requirements and Test Methods”. It can be equipped with ISG, DL, IS, S, D, DG and other pumps respectively, forming various structural types such as pipeline type, vertical multi-stage, horizontal single-stage cantilever type, horizontal split, horizontal multi-stage, etc. It can be used under different working conditions (different power, different speed, different materials, etc.).

The electric fire pump unit mainly transports water without solid particles or liquid with a viscosity similar to water. If the medium transported by the user contains acid or alkali, it should be clarified with the company when ordering. The temperature of the transported medium is 0°C~+80°C. If appropriate cooling measures are adopted, the medium with a higher temperature can be transported.