Easy Maintenance and Long Lifespan Diesel Fire Pump: A Strong Support for Firefighting Systems

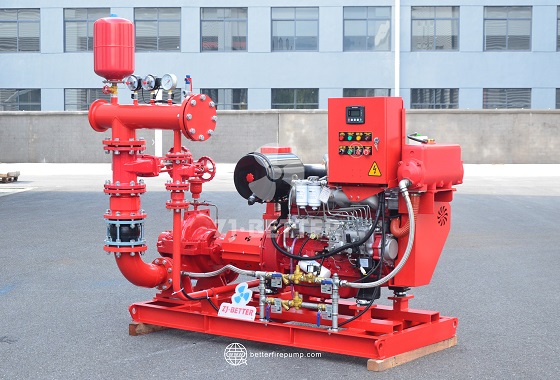

High-performance diesel engine fire pumps are known for their independent power drive, rapid start-up, and stable water supply, making them suitable for critical locations such as high-rise buildings, industrial plants, ports, and airports. Their intelligent control system, durable structure, and efficient operation ensure a reliable fire-fighting water supply even during power outages, making them an ideal choice for ensuring fire safety.

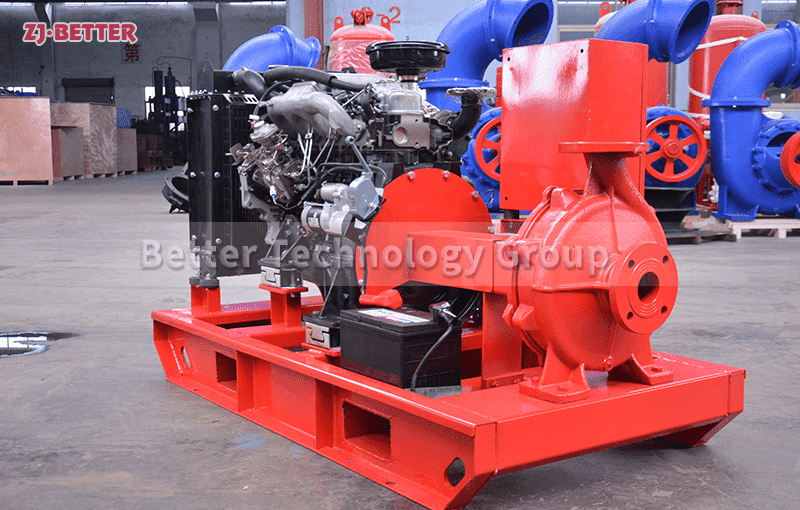

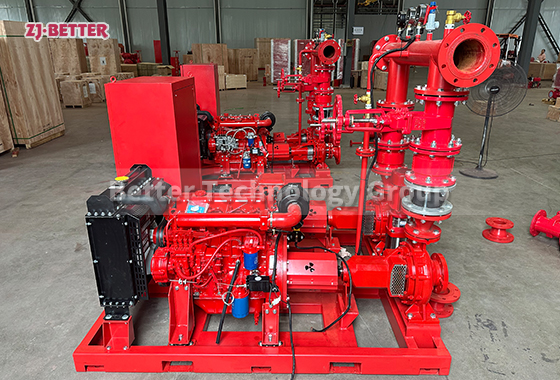

Diesel engine fire pumps, as a crucial component of fire protection systems in modern buildings, industrial facilities, and large public infrastructures, are key equipment for ensuring the safety and continuous operation of fire water supply systems due to their superior stability, reliable independent operation capability, and efficient emergency response performance. In fire emergency water supply systems, power outages pose a significant potential risk, while diesel engine fire pumps, with their independent power source and powerful mechanical performance, effectively avoid water supply interruptions caused by power failures, providing strong technical support for fire safety. This equipment not only boasts excellent start-up response speed and stable flow output but also maintains efficient operation in extreme environments, truly achieving the emergency fire protection requirement of “always on standby, reliably providing water.” The core advantage of diesel engine fire pumps lies in their independent drive system, using a high-performance diesel engine as a power source, enabling rapid start-up in completely power-free environments. Modern diesel engine design incorporates advanced technologies such as electronic fuel injection, turbocharging and intercooling, automatic preheating, and intelligent control, allowing the equipment to maintain stable starting performance even in complex environments such as low temperatures, high altitudes, and high humidity. Its starting system typically includes electric start and an automatic battery charging system, ensuring one-button rapid start-up even during long standby periods. Furthermore, diesel engine-driven systems possess strong overload capacity and continuous operation capability, enabling stable water supply under prolonged high-load conditions. This is crucial for fire protection systems in high-rise buildings, petrochemical plants, power plants, and ports. In terms of structural design, diesel engine fire pumps typically employ an integral base design, with the engine and pump body connected via a high-strength flexible coupling. This ensures transmission stability while effectively reducing vibration and noise. The pump body is mostly constructed from high-strength cast iron or stainless steel, with optimized internal flow channels to minimize hydraulic losses and improve pump efficiency. The sealing system utilizes mechanical seals or double-end face seals, maintaining excellent sealing performance under high pressure and high temperature environments to prevent leakage. The equipment is also equipped with a high-performance cooling and exhaust system to ensure the diesel engine maintains optimal operating temperature during extended operation, thereby extending its service life. The control system is another major highlight of diesel engine fire pumps. Modern diesel engine fire pumps often employ intelligent control cabinets, enabling automatic detection, automatic start-up, automatic switching, and remote monitoring functions. When the system detects a drop in pressure in the main fire protection network or receives a fire signal, the control system immediately issues a start command. The diesel engine automatically ignites and drives the water pump to provide fire water supply as quickly as possible. The control system features both automatic and manual operating modes, is easy to operate, and supports integration with building fire monitoring systems or PLC control systems for intelligent management. Furthermore, the system has multiple safety protection functions, such as over-temperature protection, low oil pressure alarm, overspeed protection, and water shortage protection, ensuring safe operation under any circumstances. In terms of performance, the diesel engine fire pump features high flow rate, high head, and high efficiency. Depending on system requirements, it can be designed as a single-stage centrifugal pump, a double-suction pump, or a multi-stage pump to meet the pressure and flow requirements of different scenarios. Its flow rate ranges from tens of cubic meters per hour to thousands of cubic meters per hour, and its head can reach over 100 meters, fully meeting the fire water needs of complex locations such as large commercial complexes, industrial plants, airports, docks, and tunnels. The pump’s operating efficiency is typically over 70%, with some high-performance models even reaching 80%, effectively improving system energy efficiency and reducing long-term operating costs. Diesel engine fire pumps also boast excellent adaptability and durability. Compared to electric fire pumps, they do not rely on external power sources and can operate independently in special circumstances such as natural disasters, fires, or power outages, greatly improving the safety redundancy of fire protection systems. The engine is constructed from high-strength alloy materials, and key components undergo precision machining and heat treatment, resulting in extremely high wear resistance and corrosion resistance. Both the intake and exhaust systems and the lubrication system are precisely optimized, ensuring stable operation even after more than 8 hours of continuous operation. Furthermore, diesel engine fire pumps have long maintenance cycles; routine maintenance only requires periodic checks of the fuel, coolant, and lubrication systems, resulting in low maintenance costs and simple operation. In terms of installation and commissioning, diesel engine fire pump sets are generally shipped as complete units, including modular components such as the diesel engine, water pump, control cabinet, base, fuel tank, cooling system, and exhaust system. Users can directly connect them on-site without complex assembly, significantly shortening the construction period. The equipment supports horizontal or fixed base installation, adapting to different machine room layouts. The pump sets undergo rigorous performance testing and factory inspection to ensure that flow rate, head, and sealing fully comply with international fire protection standards such as NFPA20, ISO9001, and GB6245. Regarding environmental performance, with increasingly stringent emission standards, modern diesel fire pumps widely adopt low-emission, high-combustion-efficiency engine technology, resulting in higher fuel economy and cleaner emissions. Some models are equipped with exhaust aftertreatment systems and noise reduction devices, minimizing the environmental impact during operation. Furthermore, excellent sound insulation and vibration-damping structures significantly reduce noise levels during operation, making them suitable for urban buildings or hospitals and other locations with high noise control requirements. In summary, diesel fire pumps, with their independent power supply, high-efficiency output, durable structure, and intelligent control, have become an indispensable core device in modern fire protection systems. They not only provide a continuous and stable water supply to the fire protection system in critical moments but also achieve a balance between system safety, reliability, and economy. Whether in high-rise buildings, warehousing and logistics centers, industrial parks, ports, airports, or municipal projects, diesel fire pumps, with their superior performance and robust design, ensure that fire protection systems can respond quickly and supply water stably even in the most severe situations, providing the last line of defense for the safety of life and property.