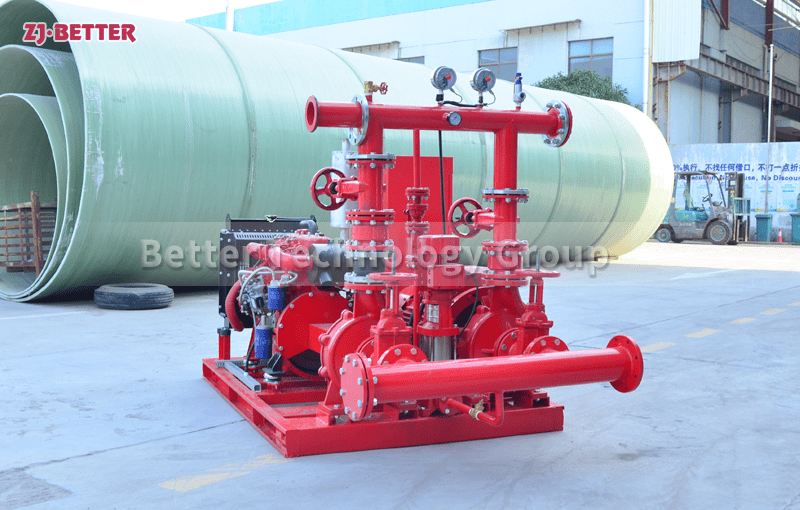

Continuous Duty Vertical Turbine Fire Pump Water Supply System

The continuously operating vertical turbine fire pump water supply system is suitable for deep wells and large-volume fire water intake scenarios. It features high head, high efficiency, and continuous and stable operation. With its reliable structure and resistance to wear and corrosion, it meets the fire water supply needs of industrial, municipal, and high-rise buildings.

The continuous-operation vertical turbine fire pump water supply system is a professional equipment specifically designed for high-reliability fire water supply needs. It is widely used in fire protection scenarios requiring long-term stable operation, where water levels fluctuate significantly, and where continuous and safe water supply is critical, such as large industrial parks, municipal fire protection projects, high-rise buildings, petrochemical plants, power plants, water treatment plants, ports and docks, and underground or semi-underground water source systems. This type of fire pump typically employs a vertical structure design, connecting the ground-based drive unit to the underwater multi-stage turbine pump body via a long shaft, achieving a perfect combination of deep water intake and high-head delivery. Its core advantage lies in its ability to maintain stable hydraulic performance and continuous, uninterrupted operation under complex water intake conditions. The entire system’s structural design fully considers long-term reliability and durability. The pump body’s hydraulic components utilize a high-efficiency turbine impeller structure, and the inter-stage flow channels are precisely calculated and optimized, resulting in smoother water flow within the pump, significantly reducing hydraulic losses and energy consumption. This ensures high flow output while effectively improving head performance, thus meeting the practical needs of long-distance, high-head fire water supply. The long shaft system uses a multi-segment shaft connection and is stably supported by intermediate guide bearings. The guide bearings are typically designed with water-lubricated or self-lubricating materials, maintaining good wear resistance and stability even under continuous operation, effectively avoiding vibration and noise problems caused by shaft oscillation or eccentricity, fundamentally extending the service life of the entire machine. To adapt to the characteristics of fire protection systems—ready to start at any time, long-term standby, and requiring continuous stable operation once started—this continuous-operation vertical turbine fire pump is particularly rigorous in material selection. Key flow-through components such as the pump casing, impeller, and shaft sleeve can be made of cast iron, stainless steel, or corrosion-resistant alloy materials depending on the media conditions, ensuring good corrosion resistance and wear resistance even in environments with long-term submersion, complex water quality, or containing certain impurities. The drive end is usually equipped with a high-performance motor or diesel power unit. Through reasonable power matching, the pump unit operates more smoothly under rated conditions, avoiding the impact of overload or underload on system stability, and also helping to reduce energy consumption and maintenance frequency. This type of fire pump is particularly outstanding in its performance. Its design goal is not only instantaneous high-flow output, but also emphasizes the ability to maintain performance under prolonged continuous operation. Even when continuous water supply is required for several hours or even longer during fire fighting operations, the pump unit can still maintain stable flow and pressure output, without problems such as excessive temperature rise, efficiency degradation, or mechanical failure, providing a reliable water source for the fire fighting system. In terms of system integration, continuous-running vertical turbine fire pump water supply systems can usually be combined with fire control cabinets, pressure monitoring devices, water level detection systems, and automatic start-stop control logic to achieve real-time monitoring and intelligent management of the pump unit’s operating status. In emergency situations, it can quickly respond to start commands, and in non-emergency situations, it can maintain a good standby state, thus balancing safety and economy. Its vertical structure occupies a small footprint, making it particularly suitable for engineering environments with limited pump room space or compact water intake well layouts. At the same time, the ground-level drive unit facilitates daily inspection and maintenance, reducing the difficulty and cost of subsequent operation and maintenance. Overall, the continuous-running vertical turbine fire pump water supply system, with its efficient and stable hydraulic performance, structural advantages adaptable to deep water and complex working conditions, excellent continuous operation capability, and good system compatibility, has become an indispensable piece of equipment in high-standard fire protection engineering. It can not only provide reliable fire water support at critical moments but also maintain stable performance during long-term operation, providing a solid guarantee for the safe operation of various fire fighting systems.