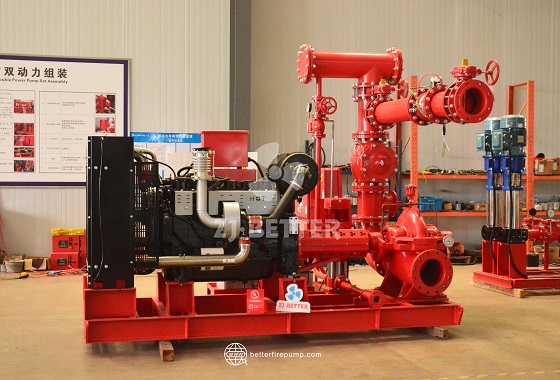

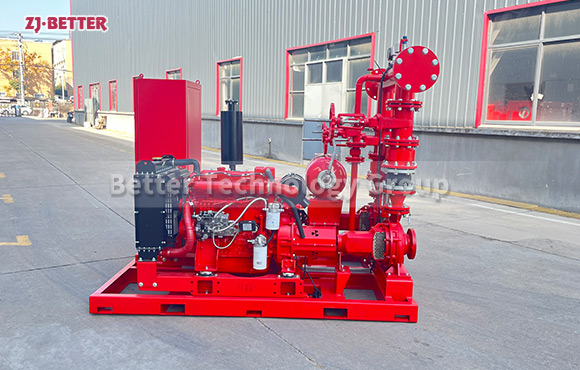

UL/FM Certified Diesel Fire Pump Set: Globally Trusted Firefighting Equipment Solution

Discover the ZJ-Better UL/FM certified diesel fire pump system – a globally trusted fire protection solution engineered for high performance, reliability, and compliance with international safety standards. Ideal for industrial, commercial, and municipal applications.

The ZJ-Better UL/FM-certified diesel fire pump set is a professional firefighting equipment solution that has been certified by internationally recognized authorities, offering high reliability, performance, and safety. It is specifically designed to meet the stringent requirements for fire protection systems in industrial, commercial, municipal, and high-risk industries worldwide. This diesel-driven fire pump set fully complies with the technical specifications and performance standards of UL (Underwriters Laboratories) and FM (Factory Mutual), two leading international certification bodies. It achieves industry-leading standards in quality control, material selection, manufacturing processes, operational testing, and system integration. UL/FM certification not only signifies that the product meets fire safety regulations in North America and globally but also symbolizes its superior performance in continuous high-pressure water supply, emergency startup response, and equipment stability, providing customers with reliable fire suppression assurance. The ZJ-Better diesel fire pump set is driven by an efficient and energy-saving diesel engine, ensuring continuous water supply capability even during power outages, voltage fluctuations, or sudden disasters. Its automatic start-up system can rapidly activate and begin operation within 15 seconds upon receiving a fire alarm signal, ensuring swift fire suppression during the initial stages of a fire. The entire system includes key components such as a diesel engine, horizontal end-suction or split-case multistage centrifugal pump, fuel system, cooling system, control cabinet, battery starting system, vibration-damping base, and coupling. The design is compact and structurally sound, and can be customized to meet the specific requirements of different projects. The control system is equipped with an intelligent microcomputer controller, supporting Chinese and English operating interfaces, and features self-diagnosis, automatic start, automatic stop, fault alarm, and operation record functions, significantly enhancing operational convenience and maintenance efficiency. The pump set has obtained FM and UL certifications, indicating its excellent fatigue resistance, outstanding continuous operation capability, and robust corrosion protection performance. It is suitable for complex environments such as high temperatures, high humidity, high dust levels, and high salt fog, and is widely applied in critical facilities such as petrochemical plants, power stations, airports, data centers, subways, high-rise buildings, hospitals, and ports. ZJ-Better strictly adheres to the ISO 9001 quality management system during manufacturing. All pump bodies are made of high-strength cast iron or stainless steel, with impellers dynamically balanced to ensure optimal hydraulic efficiency. The shaft sealing system uses mechanical seals or packing seals to effectively prevent leaks and extend service life. The base is constructed using high-strength channel steel welded structures, with an overall powder-coated finish, providing exceptional load-bearing capacity and seismic resistance, ensuring high stability during transportation, lifting, and on-site installation. To ensure long-term stable operation of the pump system, ZJ-Better offers multiple optional additional features, such as an automatic fuel replenishment system, remote monitoring modules, temperature-controlled heating devices, noise reduction and soundproofing treatments, and containerized pump room integrated solutions. Customers can flexibly configure these options based on their specific application requirements. Additionally, pre-sales support includes selection guidance, mid-sales support includes installation and commissioning arrangements, and post-sales support includes 24/7 technical support and global warranty services, ensuring a worry-free user experience throughout the product lifecycle. The ZJ-Better diesel fire pump set is renowned in the international market for strictly adhering to NFPA 20 standards. Each pump set undergoes rigorous testing for five performance metrics—flow rate, head, efficiency, net positive suction head (NPSH), and startup time—prior to shipment, with comprehensive test reports issued to ensure optimal performance before delivery. Additionally, the pump set has been successfully applied in key fire protection projects across Southeast Asia, the Middle East, Africa, and South America, demonstrating strong competitiveness in international engineering tenders. Backed by UL/FM certification, ZJ-Better has become the preferred brand for many EPC contractors, fire protection contractors, design institutes, and end-users, enhancing project compliance and safety while providing users with higher asset protection levels and insurance support. Whether in petrochemical facilities requiring 24/7 operation or data center server rooms with extremely high reliability requirements, the ZJ-Better diesel fire pump set consistently stands out with its comprehensive advantages of outstanding performance, stable quality, intelligent control, and low maintenance costs, establishing itself as a leader in the international fire pump industry. As global fire safety requirements continue to evolve and driven by trends toward intelligent and green technologies, ZJ-Better is continuously increasing its investment in product R&D and system integration. While maintaining its UL/FM certification advantages, it continues to introduce cutting-edge solutions such as multi-functional combined pump stations, environmentally friendly and energy-efficient power systems, and remote intelligent control platforms. This provides customers with not just a pump set, but a complete, efficient, intelligent, and safe fire protection water supply solution. Choosing ZJ-Better UL/FM-certified diesel fire pump sets is not just about selecting a product; it is about embracing global engineering quality standards, a comprehensive safety assurance system, and professional technical service capabilities. These systems not only save lives and assets in critical moments but also quietly safeguard business operations every second of every day, making them indispensable core equipment in modern high-standard fire protection systems.