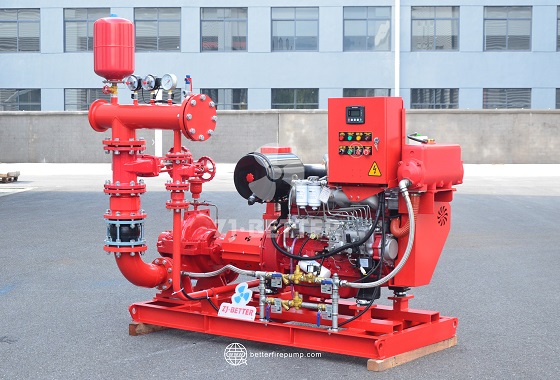

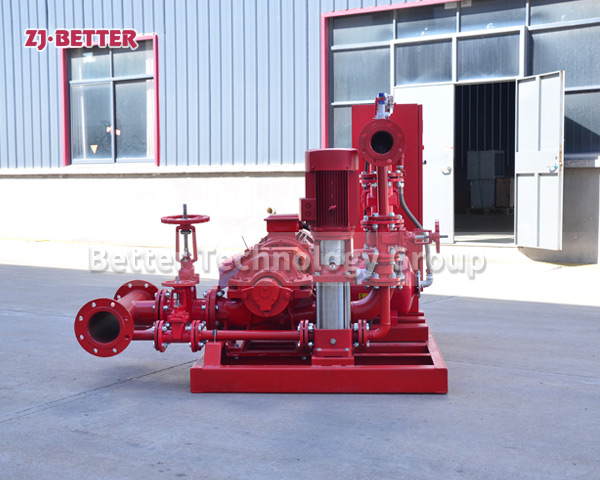

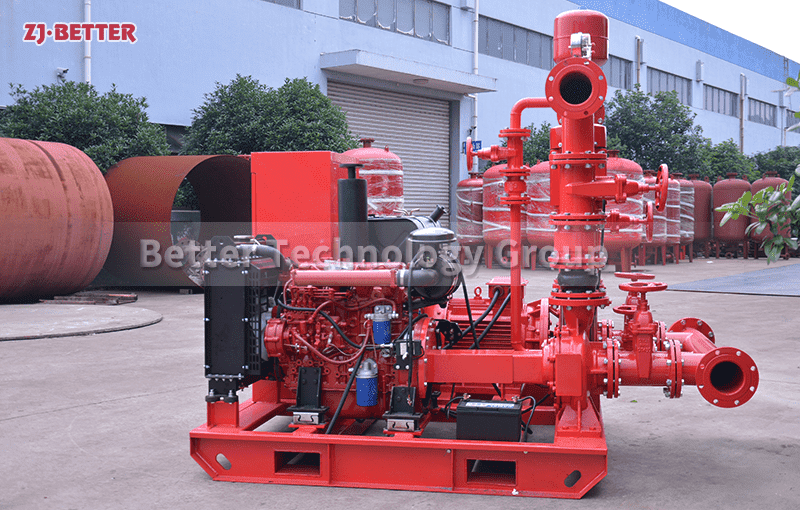

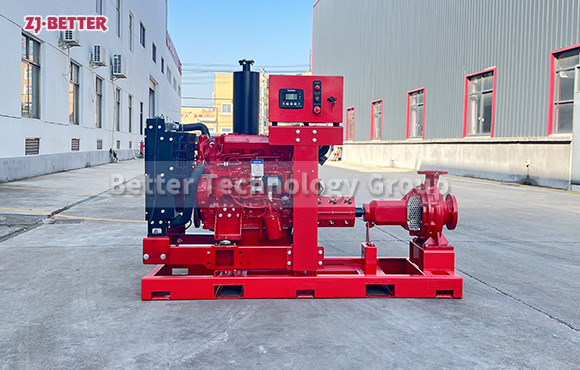

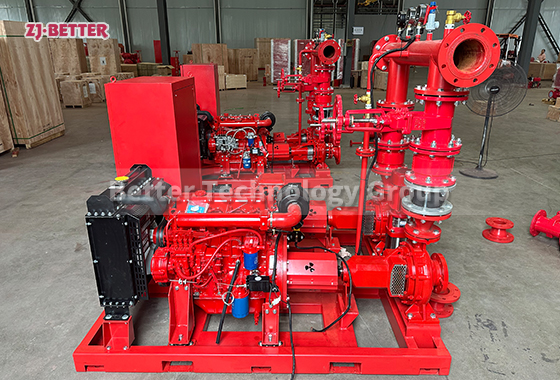

Assembled EDJ Fire Pump

Scope of application of fire pump set:

1. Industrial plants, automobiles, breweries, pulp and paper, chemicals, pharmaceuticals;

2. Government offices, embassies, military bases, administrative buildings;

3. Commercial buildings, high-rise buildings, hotels, office buildings, warehouses;

4. Various institutions, hospitals, labor camps, sanatoriums, schools;

Fire pumps are one of the most important components of a property¡¯s fire protection system. It is the pressure-increasing component of the water supply for fixed fire suppression systems like fire sprinklers, standpipes, etc.

A fire pump set consists of one main pump that is connected to an electric motor, a stand-by pump connected to a diesel engine, jockey pump, pressure vessel, controller for manual or automatic operation of the system and the other standard accessories that are mounted on the base frame of the pump set.

The fire pump is part of the fire sprinkler system. It receives water from either an underground water supply or water tank, reservoir, lake, etc. It is powered by either electricity or diesel fuel. The high pressure supplied by the pump distributes water through the sprinkler system and hose standpipes.