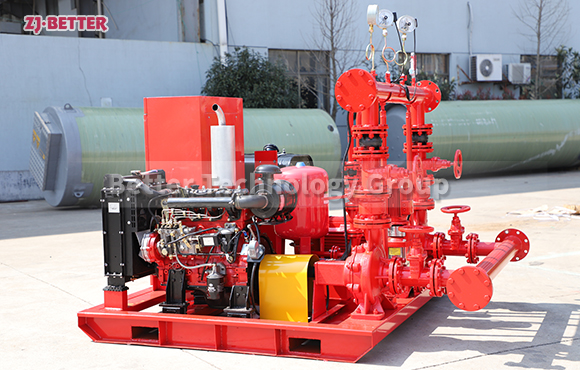

Heavy-Duty Diesel Fire Pump Set for Harsh Conditions with Long-Lasting Performance

Heavy-duty diesel fire pump sets are suitable for industries such as industry, ports, chemicals, and power stations. They feature large flow, high head, automatic control, and corrosion-resistant design to ensure stable water supply during power outages or emergencies.

Heavy-duty diesel fire pump sets are emergency equipment designed to provide stable and efficient water supply in harsh operating conditions. They are widely used in industrial areas, ports, oil depots, chemical plants, power plants, large warehouses, and municipal fire protection systems. Powered by a high-power diesel engine, they operate independently of utility power and can quickly start in the event of a power outage, disaster, or other emergency, ensuring an adequate water supply to the fire protection system. These pump sets typically feature a high-strength base and sturdy frame to ensure stability in long-term operation and challenging environments. The wear-resistant and corrosion-resistant pump body material significantly extends their service life. Heavy-duty diesel fire pump sets demonstrate exceptional high head and high flow capacity, meeting the requirements of multi-story buildings, large-span factory buildings, and long-distance water transmission. They are equipped with advanced fuel supply and cooling systems to maintain optimal engine operating temperature under prolonged high loads, ensuring continuous and stable power output. Heavy-duty diesel fire pump sets often feature both electric and manual starting modes, ensuring manual override in the event of electronic control system failure, enhancing emergency reliability. In addition, some models are equipped with an automatic control cabinet that receives signals from the firefighting system for automatic start and stop. It also features real-time monitoring and alarm functions for various operating parameters, including water pressure, water flow, speed, oil pressure, and temperature. Abnormalities trigger audible and visual alarms or automatic shutdown protection, effectively preventing equipment damage. Given the high temperatures, smoke, humidity, and corrosive substances often associated with firefighting environments, heavy-duty diesel fire pump sets are designed with high-grade electrical components and anti-corrosion coatings. The outer shell is sprayed with anti-rust paint, and the base and piping feature anti-vibration and shock-absorbing designs to minimize vibration damage to pipes and fittings. The power unit utilizes a rigorously tuned diesel engine, offering high torque output, low fuel consumption, and compliant emissions. Some models meet European and American emission standards, making them suitable for export. The pump body utilizes an optimized hydraulic model to maximize hydraulic efficiency and minimize energy loss. The sealing system prevents leaks and extends bearing life. Heavy-duty diesel fire pump sets are also highly adaptable, capable of fixed installation in a pump room or converted to a mobile trailer for rapid deployment in the field or for temporary firefighting missions. Furthermore, it is compatible with a variety of water sources, including municipal water, groundwater, rivers, and lakes, enabling rapid deployment even in areas lacking a reliable piped water supply. Regarding maintenance, the equipment layout is well-organized, with easily accessible maintenance points, reducing the time and effort required for routine maintenance and overhauls. The ample fuel tank capacity supports long-term continuous operation, making it suitable for long-term emergency response missions. Modern heavy-duty diesel fire pump units not only offer superior hardware performance but also integrate with intelligent firefighting systems for remote monitoring and management. Wireless communication modules transmit operational data to a control center, enabling managers to instantly understand equipment status and make informed decisions. Overall, heavy-duty diesel fire pump units combine high reliability, high performance, durability, and flexible deployment capabilities, making them particularly suitable for firefighting operations requiring long-duration, high-intensity water supply. Whether in scorching summers or freezing winters, or in highly corrosive and dusty environments, they maintain stable operation, ensuring critical firefighting safety and providing a solid foundation for industrial production and public safety. The design concept of this equipment is not just simple water supply, but through all-round reliability and intelligent protection, it can help users win precious time at critical moments, thereby greatly improving the success rate of fire extinguishing and reducing fire losses.