Diesel-Driven Fire Pump Units: The Top Choice for Industrial and Municipal Projects

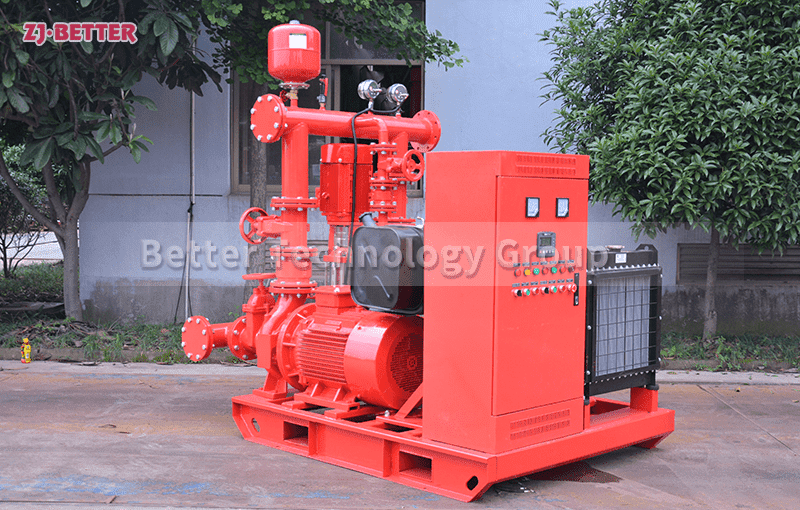

The diesel engine-driven fire pump complete set highlights its ability to supply water independently even in the event of power failure or emergency. The product integrates diesel engine, water pump, control system and piping system, with automatic start, stable performance, convenient operation and other characteristics. It is suitable for all kinds of places with high requirements for fire fighting, such as industrial parks, petrochemicals, power plants and municipal projects, etc., and is an important equipment for ensuring fire safety.

As industrial development and urban infrastructure continue to evolve, ensuring reliable water supply during fire emergencies has become critical for engineering projects. Diesel-driven fire pumps stand out as essential components for fire protection systems in petrochemical facilities, power plants, municipal networks, water treatment stations, and transport hubs, thanks to their independent operation, robust performance, and adaptability to complex conditions.

Our diesel fire pump sets are powered by globally recognized diesel engine brands, paired with high-head, high-flow centrifugal or end suction pumps. Featuring a compact, modular design, these systems are optimized for all-weather, all-terrain deployment. They are certified and customizable to comply with NFPA 20, UL, ISO9001, and other global standards, making them ideal for a wide range of applications.

Key Technical Features:

-

Automatic Emergency Start

Equipped with a fully automated start system, the unit responds to fire alarms within 10 seconds, immediately delivering pressurized water to firefighting systems. -

Independent from Power Grid

In disaster scenarios like earthquakes, floods, or power failures, the diesel fire pump continues to deliver uninterrupted water supply without relying on external electricity. -

Modular All-in-One Design

The system integrates the engine, pump, controller, fuel tank, and cooling system into a single skid-mounted unit. Easy to install and transport, it is ideal for prefabricated containers, underground stations, or tight spaces. -

Durable & Environment-Resistant

With pump bodies made of ductile iron or stainless steel, and corrosion-resistant coatings, the system is built to endure harsh conditions such as heat, humidity, and dust. -

Smart Monitoring & Remote Control

An intelligent control panel enables automatic inspection, data logging, fault alerts, remote start, and real-time system monitoring—enhancing operational efficiency and reliability.

Wide Range of Applications:

Perfect for industrial plants, petrochemical zones, LNG storage sites, power stations, waterworks, urban utility tunnels, airports, subway stations, ports, and integrated commercial complexes—especially in areas where power stability is a concern.

Full-Service Support:

We offer a complete service package including system design, pump selection, factory testing, on-site commissioning, user training, and spare parts supply. Every unit undergoes full-capacity testing before shipment to ensure performance reliability.

By choosing our diesel fire pump systems, you’re not just investing in a product—you’re adopting a fully integrated, reliable, and future-ready fire protection solution.