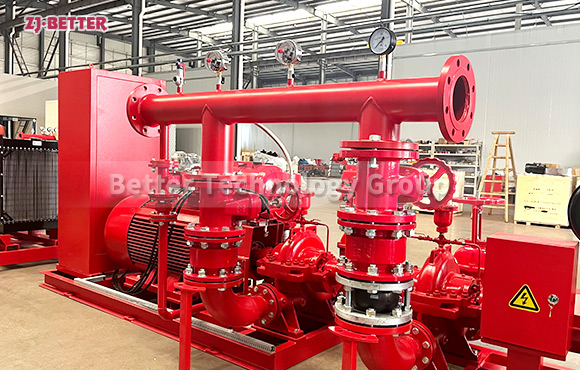

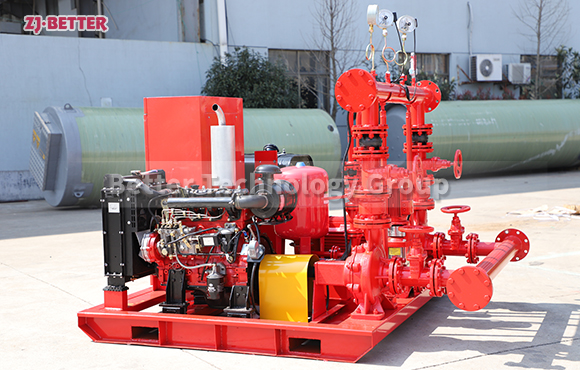

Dual-Power Fire Pump System: Diesel & Electric Backup for Reliable Water Supply

The integrated fire pump unit adopts a modular design, incorporating the pump, drive equipment, control system, and pipeline components into a single base to enhance system stability and ease of installation. This equipment is suitable for high-rise buildings, industrial facilities, the petrochemical industry, and other locations with high fire protection requirements.

The unit is equipped with a high-performance electric motor or diesel engine as a power source, ensuring a stable water supply in emergency situations. The pump features a high-head and large-flow design, meeting various firefighting demands and ensuring rapid water delivery in case of fire. The intelligent control system continuously monitors operating conditions and can automatically start or stop the pump according to preset parameters, improving fire response efficiency.

With a compact structure and small footprint, the unit is ideal for installations with space constraints. The optimized pipeline and valve design reduce fluid resistance and enhance transportation efficiency. Constructed from corrosion-resistant materials, the system ensures long-term operational stability and durability while minimizing maintenance requirements.

This integrated fire pump unit complies with relevant international standards, making it suitable for different regional fire safety regulations and widely applicable to various scenarios requiring efficient and reliable fire water supply.

The company specializes in the development and production of high-performance fire pump systems, committed to providing global users with efficient, safe, and stable fire water supply solutions. Our product range includes electric fire pumps, diesel-driven fire pumps, dual-power pump units, pressure-maintaining pump sets, and fully integrated intelligent fire water supply systems, widely used in high-rise buildings, industrial plants, energy and chemical industries, and infrastructure projects.

All products incorporate high-head, large-flow, and rapid-response core technologies, ensuring a stable water supply during fire emergencies. The application of smart control systems enables features such as automatic start-stop, remote monitoring, and self-diagnosis of faults, enhancing equipment reliability and ease of management.

Manufactured in strict compliance with international fire protection standards (such as NFPA, UL, FM, CCCf, etc.), each unit undergoes rigorous testing to ensure high efficiency and stability even in extreme environments. The company is also dedicated to technological innovation, optimizing pump structures, improving energy efficiency, and reducing power consumption to provide more eco-friendly fire water supply solutions.

With strong technical support and outstanding product performance, the company delivers customized fire pump systems for various global construction and industrial projects, ensuring fire safety and protecting lives and property.