Home » Fire Pump Set » How to start and stop fire pump set?

How to start and stop fire pump set?

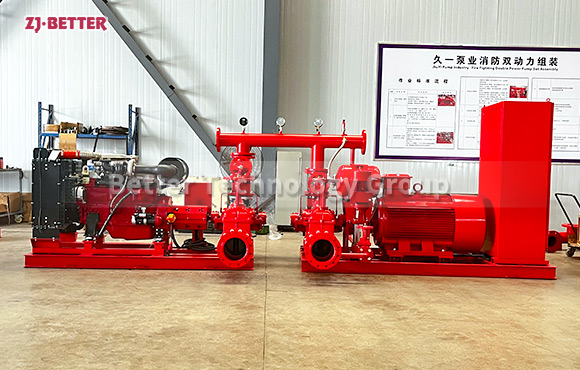

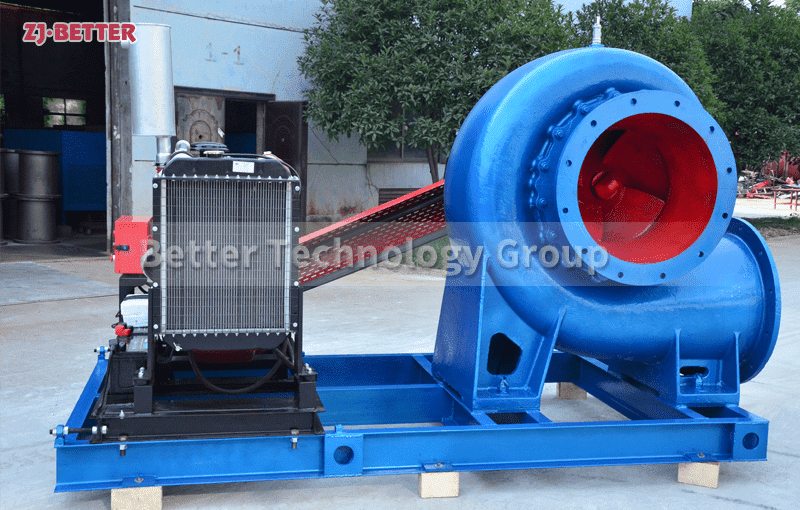

If the person on duty in the fire control room cannot start and stop the fire pump manually after the fire occurs, it will delay the timing of emergency rescue and fire extinguishing. Today ZJBetter is here to explain how to switch the working status of the electrical control cabinet of the fire pump, manually start and stop the pump group on site and remotely, so that everyone can use the fire pump to extinguish the initial fire source or slow down the fire before the fire rescue comes.

Contact US

Get Price

Share:

Content

Step 1: Check that the system is in good working condition.

Step 2: Operate the control cabinet panel to implement manual/automatic switching and main/standby pump switching. As shown in the figure below: a automatic mode (1 master and 2 backup); b manual mode; c automatic mode (2 master and 1 backup)

When the transfer switch is in the middle gear, it represents the manual operation state. The start/stop of the fire pump is operated through the start button on the control cabinet panel, and the automatic control is invalid. When the transfer switch is turned to the left gear, it means that the 1# pump is the main pump and the 2# pump is the backup pump, which is referred to as 1 master and 2 backup pumps; when the transfer switch is turned to the right gear, it means that the 2# pump is the main pump and 1# The pump is a standby pump, referred to as 2 main and 1 standby. Regardless of whether the transfer switch is in the left gear or the right gear, it represents the automatic running state. At this time, the system can realize the function of automatic start of the main pump, and the manual control of the control cabinet panel is invalid. During operation, when the main pump fails, the backup pump can be put into operation automatically.

Step 3: Implement the master/standby power switching operation. Taking a certain type of dual power switch (as shown in the figure below) as an example, the main/standby power switching operation is as follows:

Check to confirm that the current power supply status is normal power supply (N in R split), and the indicator light of N power supply (common power supply) is on. Set the operating mode switch to manual mode. Rotate the handle to the standby power supply state (N points and R closes), and observe that the N power indicator is off, and the R power (standby power) indicator is on.

Rotate the handle to the normal power supply state, and switch the operating mode switch to automatic mode.

Step 4: Simulate the failure of the main power supply and the main pump respectively, and test the automatic operation of the backup power supply and the backup pump. Check to make sure that the dual power supply switch is in the automatic operation mode, cut off the main power supply, observe that the backup power supply is switched on automatically and restore the main power supply. Confirm that the control cabinet is in the automatic operation mode, and for the automatic sprinkler system, use methods such as releasing water from the terminal water test device to make the pressure switch actuate. After the main pump starts and runs smoothly, simulate the failure of the main pump (cut off the switch of the main pump or simulate the action of the thermal relay of the main pump. The thermal relay is shown in the figure below. Observe that the standby pump should be automatically put into operation. After the pump is manually stopped, the system will return to normal operation.

Step 5: Implement manual start and stop fire pump operation. Confirm that the control cabinet is in manual operation mode. Press any fire pump start button, and observe the instrument, indicator light, motor operation, etc. Press the corresponding fire pump stop button, and observe the instrument, indicator light, motor operation, etc. The control cabinet returns to automatic operation mode.

Inquiry

More Fire Pump Set