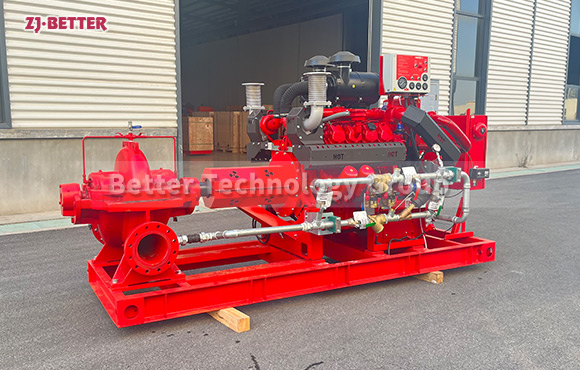

750gpm EDJ pump set

750gpm fire fighting package set

120≤ Q≤1000GPM

H<150m

The EDJ fire pump group is composed of electric pump + diesel pump + jockey pump. The three pumps are automatically started and stopped. When the stabilized pump detects that the electric pump cannot operate normally, the diesel engine pump will start automatically. Can also be used, the fire pump set is widely used in various emergency firefighting occasions.

According to customer’s requirements, it can be combined freely to realize the function of small fire fighting package set water supply equipment.

ED or EDJ or EEDJ or EEJ ect..

ED: An electric main pump and a diesel engine standby pump (without voltage stabilization or where voltage stabilization is individually configured)

EDJ: An electric main pump, a diesel engine standby pump and a Jockey pump. This diesel-electric combination is more stable..

EEJ: Two electric pumps (one duty and one standby) , plus one Jockey pump, are also feasible for places where power supply is stable or where there are self-allocated generators.

DJ: A diesel engine main pump, a jockey pump (used in the place where the pump runs entirely through the diesel engine)