How to Enhance the Stability and Energy Efficiency of Fire Pump Systems?

Enhancing the stability and energy efficiency of fire pump systems is crucial for fire safety. Our fire pumps are crafted from high-quality materials and produced with advanced manufacturing techniques, ensuring excellent corrosion resistance and long-lasting durability. Equipped with high-efficiency motors and intelligent control systems, they significantly reduce energy consumption while guaranteeing efficient output during fire emergencies. The unique vibration reduction and noise suppression design ensures stable and reliable operation, unaffected by external environmental factors. Whether for high-rise buildings or industrial facilities, our fire pumps provide consistent and lasting protection.

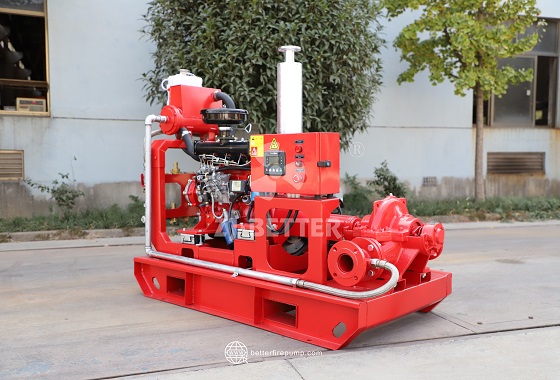

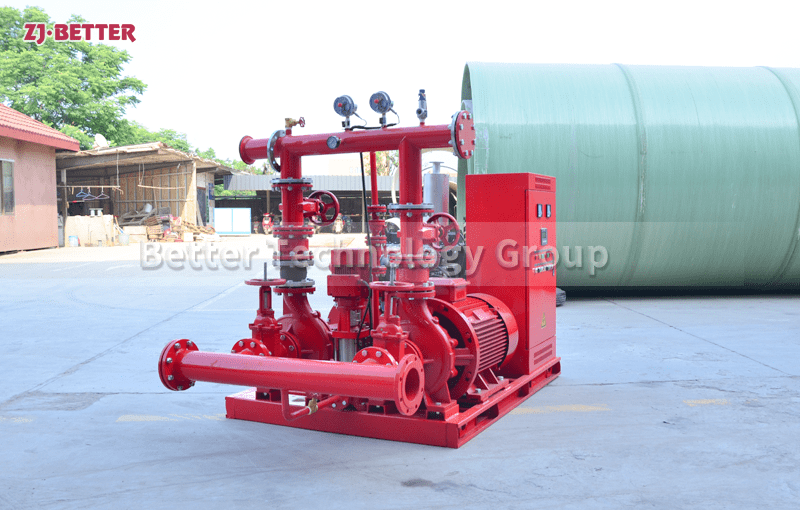

We are a company specializing in the research and manufacturing of fire pump systems, dedicated to providing efficient and safe fire pump solutions for various buildings and industrial facilities. Our products include electric fire pumps, diesel engine fire pumps, and constant pressure water supply equipment, widely used in high-rise buildings, factories, commercial complexes, and municipal projects.

With advanced production technology and strict quality management, our fire pumps are characterized by high efficiency, durability, and user-friendly operation. Each unit undergoes rigorous testing before leaving the factory to ensure stable performance during critical moments. We also offer comprehensive technical support and after-sales services, ensuring peace of mind for our customers.

Adhering to the principle of “Quality First, Customer Priority,” we continually innovate and enhance product performance, striving to provide professional and high-quality fire pump products and system solutions to clients worldwide.