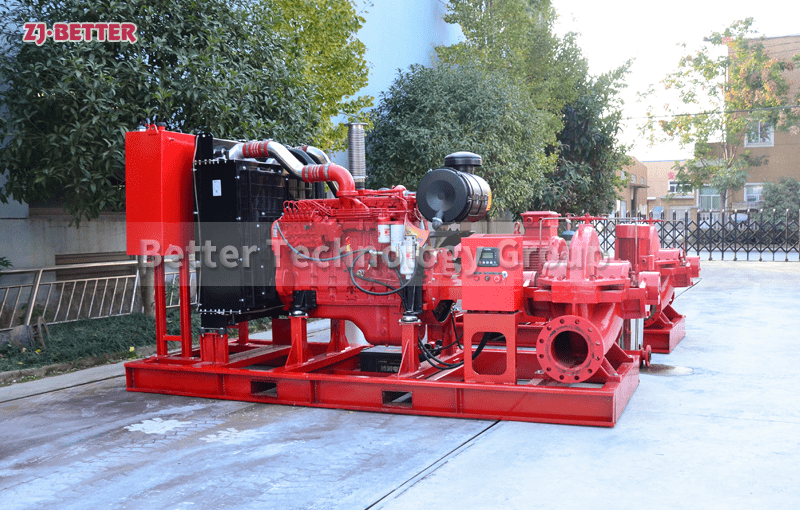

Fixed Vertical Fire Pump Unit Designed for Continuous Fire Pipeline Supply

The stationary vertical fire pump unit has a compact structure, small footprint, rapid start-up, high head, stable flow, and reliable operation. It is suitable for high-rise buildings, industrial plants, and municipal fire protection systems, providing a continuous and stable emergency water supply guarantee for fire protection pipe networks.

Stationary vertical fire pump units are core fire-fighting equipment designed for continuous and stable water supply to fire protection networks. With a compact structure and rational layout, they can quickly activate at the first sign of a fire and continuously supply fire-fighting water to the system, meeting design pressure and flow requirements. They are an indispensable component of modern building fire protection engineering, municipal fire protection systems, and industrial fire protection facilities. These fire pump units typically employ a vertical structure design, offering significant advantages over traditional horizontal designs in terms of floor space, installation space utilization, and pipeline layout flexibility. They are particularly suitable for applications with limited pump room space or requiring vertical placement close to the fire protection network. The unit utilizes a high-strength steel base combined with a vibration-damping structure to effectively reduce vibration and noise during operation, ensuring stable and reliable performance even under prolonged standby and high-load operation. The core components of the pump body are made of high-precision cast materials and undergo rigorous dynamic balancing and static pressure testing, guaranteeing excellent hydraulic performance and high operating efficiency. Under rated operating conditions, they can continuously output stable pressure, meeting the dual requirements of head and flow for complex fire protection networks in high-rise buildings, underground projects, factories, and warehouses. Fixed vertical fire pump units are designed with the reliability requirements of fire protection systems in mind. The pump shaft is made of high-strength alloy steel and undergoes heat treatment, providing excellent fatigue resistance and wear resistance. Combined with a high-quality bearing system, this significantly extends the overall service life of the unit and reduces maintenance frequency. For the sealing structure, high-temperature and corrosion-resistant mechanical seals or combined seals are commonly used to effectively prevent media leakage and ensure good sealing performance even under high pressure and high-speed operation. This also allows the unit to withstand impurities in fire-fighting water and the start-up and shutdown shocks after long periods of stagnation. The motor typically uses a high-efficiency, low-energy-consumption industrial-grade motor with good insulation and protection performance. It can operate stably for extended periods in high-humidity and high-temperature pump room environments and can reliably integrate with the fire control system, responding quickly upon receiving a start signal, shortening system reaction time and buying valuable time for initial fire suppression. Stationary vertical fire pump units also excel in control and protection. Their integrated electrical control systems typically incorporate multiple monitoring and protection functions, enabling real-time monitoring of key parameters such as operating current, voltage, and temperature rise. They promptly issue alarms or implement protective measures in case of abnormal conditions, effectively preventing equipment damage and system failures, and enhancing the overall safety level of the fire protection system. The structural design of these units prioritizes ease of inspection and maintenance, with a rational arrangement of key components. Daily inspection and maintenance are simple, effectively reducing subsequent operation and maintenance costs. They are particularly suitable for fire protection applications requiring long-term standby time but demanding 100% reliability upon startup. In terms of performance, stationary vertical fire pump units possess excellent hydraulic characteristics. The optimized pump design results in high efficiency and good cavitation performance, effectively reducing energy consumption and operating noise while ensuring high head output. This makes them suitable for use in residential communities, commercial complexes, hospitals, schools, data centers, and various industrial plants—places with extremely high requirements for stable fire water supply. Its continuous water supply capacity is particularly outstanding. Even under long-term continuous operation, it can maintain stable flow and pressure output without easily experiencing performance degradation, fully meeting the stringent requirements of fire protection codes for continuous water supply time and system reliability. Fixed vertical fire pump units also possess excellent system compatibility, allowing for flexible configuration in various fire water supply schemes. They can form a complete fire water supply system with fire water tanks, pressure stabilizing devices, and pipeline systems, adapting to the actual needs of different engineering projects. Through reasonable selection and configuration, these units can not only improve the overall operating efficiency of the fire protection system but also achieve energy-saving operation while ensuring safety, balancing reliability and economy. With its stable structural design, excellent performance, and good adaptability, fixed vertical fire pump units have become an important piece of equipment in modern fire protection engineering to ensure continuous water supply to fire protection pipelines, providing solid and reliable technical support for building and industrial fire safety.