Worry-Free Continuous Operation: Application Advantages of High-Flow Fire Pump in Critical Sites

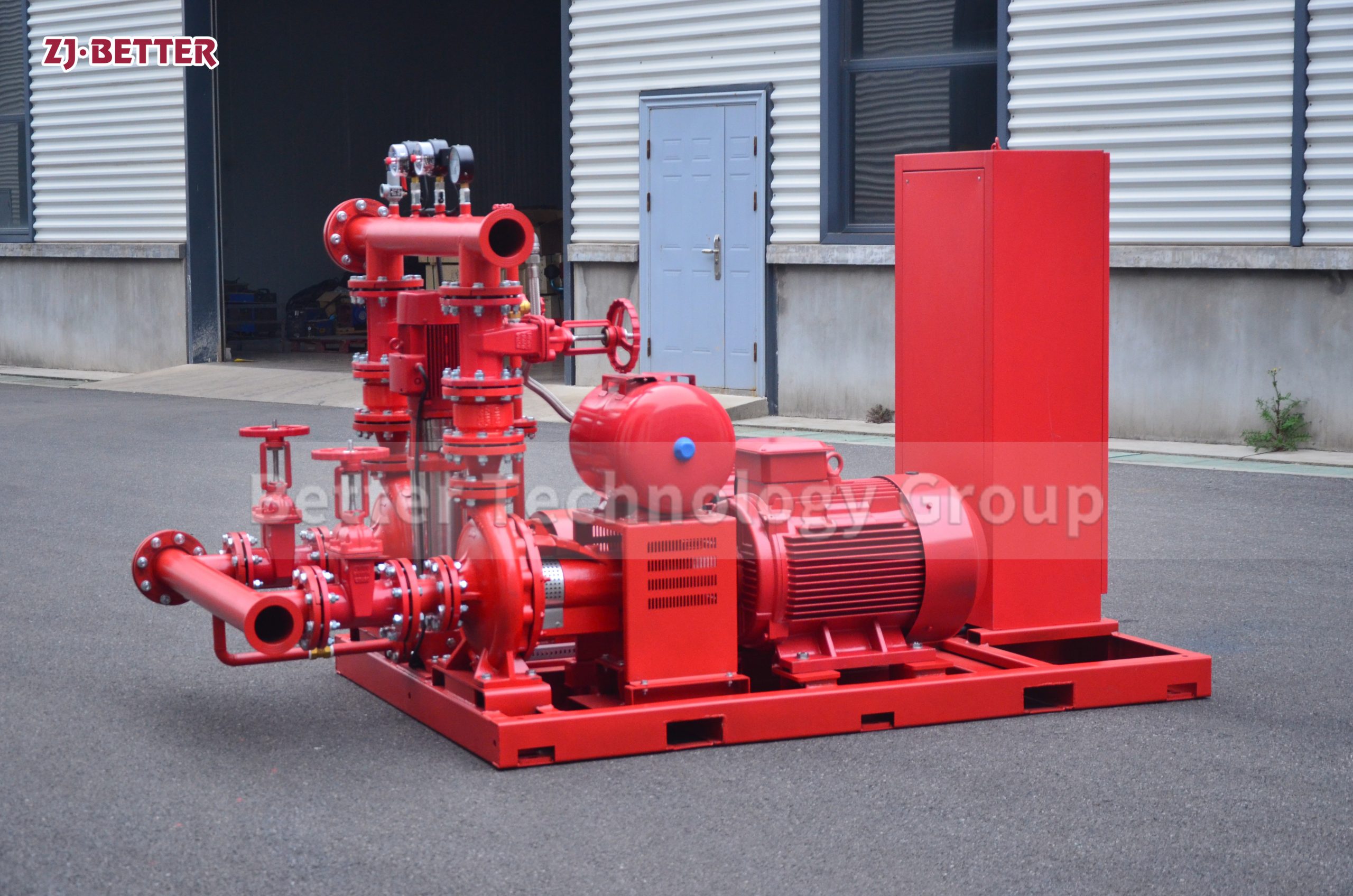

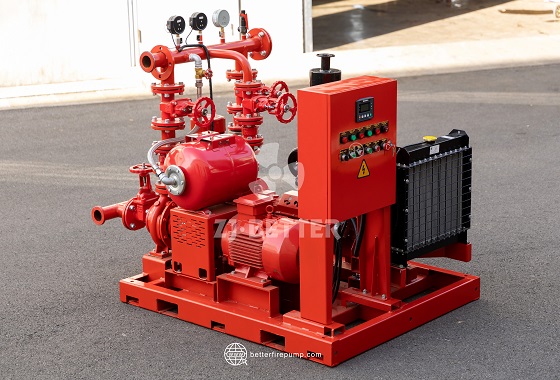

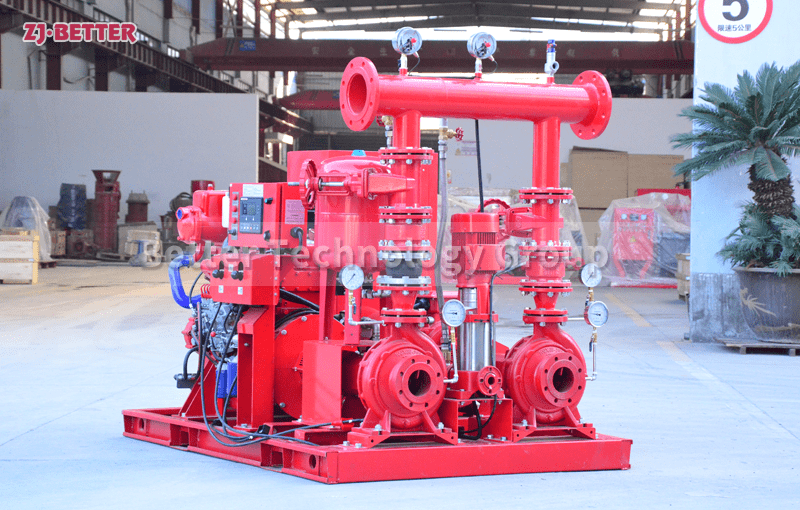

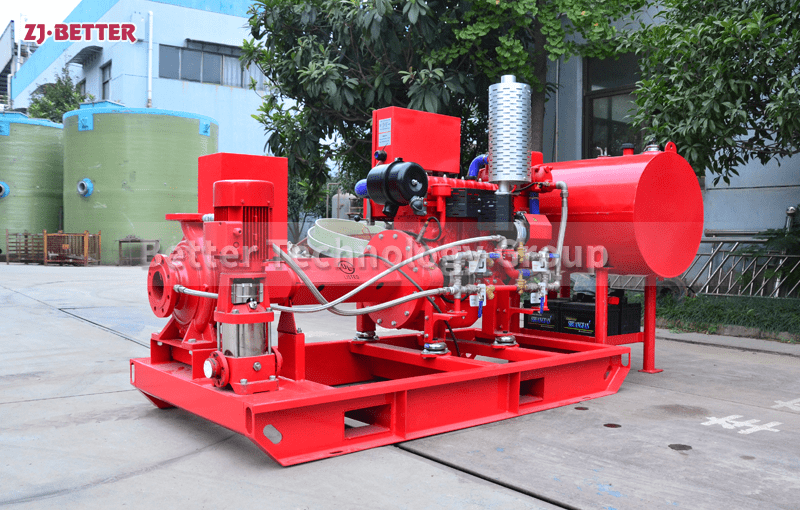

High-flow fire pumps, with their robust water supply capacity, excellent continuous operation performance, and intelligent control systems, provide reliable fire protection for critical locations such as airports, oil depots, ports, and power stations. These pumps offer energy efficiency, durability, corrosion resistance, and multiple safety features. They support both electric and diesel powertrains to meet the demands of complex environments, making them an indispensable core component in modern firefighting systems.

In modern, high-density urban and industrial environments, the reliability and sustainability of firefighting systems are crucial safety standards. High-flow fire pumps, with their robust water supply capacity and excellent continuous operation performance, play an irreplaceable role in critical locations. The design concept of this type of equipment stems from in-depth consideration of extreme fire scenarios. Its core goal is to ensure a continuous and sufficient supply of firefighting water in high-risk environments and large-scale fires, thereby buying valuable time for evacuation and fire control. The primary advantage of high-flow fire pumps lies in their robust water supply capacity. Through optimized hydraulic design and an efficient impeller structure, these pumps can rapidly deliver large volumes of water in a short period of time, meeting the demanding ultra-high-flow firefighting water supply requirements of large-scale facilities such as airports, petrochemical bases, power stations, storage centers, and ports. Compared to traditional low-flow equipment, high-flow pumps offer a superior balance between high pressure and high flow. This not only ensures stable water flow but also maintains constant pressure during continuous operation, preventing water shortages or pressure fluctuations that could impact firefighting effectiveness. A second significant advantage is their excellent continuous operation performance. High-flow fire pumps generally utilize high-temperature and wear-resistant core components, high-strength alloy materials, and optimized cooling systems. These components maintain mechanical and hydraulic stability even under prolonged, high-load operation. This characteristic is particularly useful in locations with prolonged fires, such as large chemical parks or oil depots. In such scenarios, the inability of the equipment to provide a stable water supply over a long period of time can hinder firefighting operations and dramatically increase the risk of fire. The design of high-flow fire pumps not only considers the quantity of water supplied, but also the continuity and reliability of the water supply. A third advantage lies in their flexibility and wide range of applications. High-flow fire pumps are typically available with diesel engines, electric motors, or dual-power configurations to adapt to different energy conditions and emergency response needs. In locations with unstable or even complete power outages, diesel-powered high-flow fire pumps can operate independently, ensuring uninterrupted water supply during emergencies. In modern cities with robust power supply, electric motor-powered models dominate due to their energy-saving and environmentally friendly advantages. Furthermore, some units support dual-power switching, automatically switching from electric to diesel in an emergency, providing dual protection. Furthermore, high-flow fire pumps have made significant progress in intelligent control. With the integration of modern automation and the Internet of Things (IoT), advanced fire pump systems are now commonly equipped with intelligent control systems, enabling real-time monitoring, remote control, and automatic alarms. Operators can not only precisely monitor key operating parameters such as water pressure, flow, and temperature via the control panel, but also conduct remote diagnostics and status tracking via the remote monitoring platform, significantly improving equipment efficiency and safety. The addition of intelligence has transformed high-flow fire pumps from mere mechanical equipment into intelligent safety systems, enabling them to deliver even more precise and efficient performance at critical moments. High-flow fire pumps also offer unique advantages in durability. Their modular and integrated design facilitates quick installation and ongoing maintenance. High-grade corrosion-resistant coatings and sealing ensure long-term, stable operation in harsh environments such as humidity, salt spray, and dust. This highly adaptable design ensures the equipment performs well not only in conventional locations but also maintains reliable performance in seaports, mining areas, and tropical regions with high temperatures and humidity, significantly extending its application range and service life. Energy conservation and environmental protection are also key strengths of high-flow fire pumps. By optimizing the hydraulic structure and improving power transmission efficiency, the equipment effectively reduces energy consumption and carbon emissions while ensuring efficient water supply. This not only aligns with current green development trends but also lowers users’ long-term operating costs. In some applications, the pump unit can be equipped with a variable frequency control system to achieve on-demand water supply, further reducing energy consumption without compromising firefighting performance. High-flow fire pumps also require high safety features. Designed with the complexities of fire scenes in mind, they incorporate multiple safety features, including automatic shutdown, low oil pressure alarms, and high water temperature alarms. These ensure immediate response in the event of an emergency, preventing secondary losses from equipment damage or water supply interruptions. Furthermore, these units typically undergo rigorous quality testing and fire certification to ensure compliance with international standards, providing users with reliable protection during critical moments. Furthermore, the advantages of high-flow fire pumps lie in their customization capabilities. The flow rate, head, drive mode, and control system can be flexibly adjusted to meet the needs of different industries and locations, providing tailored solutions. Whether it’s an oil depot fire extinguishing system requiring ultra-high flow or high-lift water supply for high-rise buildings, high-flow fire pumps can be customized to meet diverse needs. This flexibility not only enhances the equipment’s market competitiveness but also makes it widely accepted in various fire protection projects. Finally, the economic benefits of high-flow fire pumps are also worth considering. While their initial investment cost is relatively high, their combined advantages of high efficiency, durability, energy efficiency, and low maintenance can provide users with significant cost savings over the long term. Especially in locations with extremely high safety requirements, the value of this equipment lies not only in reducing losses but also in improving the reliability of the overall safety system. In summary, with their robust water supply capacity, excellent continuous operation performance, flexible adaptability, intelligent control system, exceptional durability, and energy-saving and environmentally friendly features, high-flow fire pumps have become an indispensable core component of fire protection systems in critical locations. They are not only a powerful tool for ensuring safety but also a concentrated reflection of the continuous advancement and development of modern fire protection technology, providing a solid and efficient safety barrier for various high-risk environments.