Modern Innovations in Fire Jockey Pumps: Smart Control and High-Precision Pressure Response

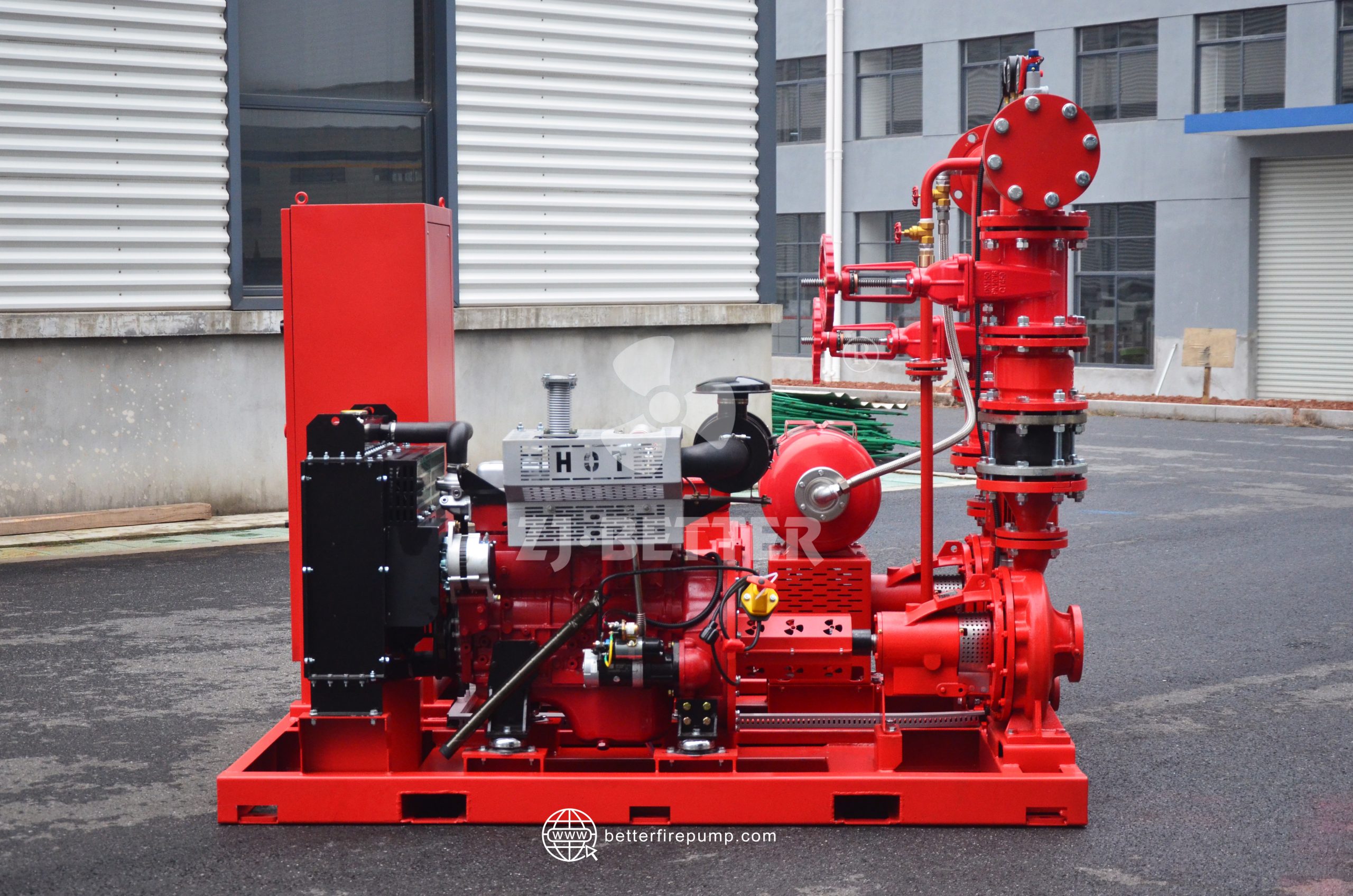

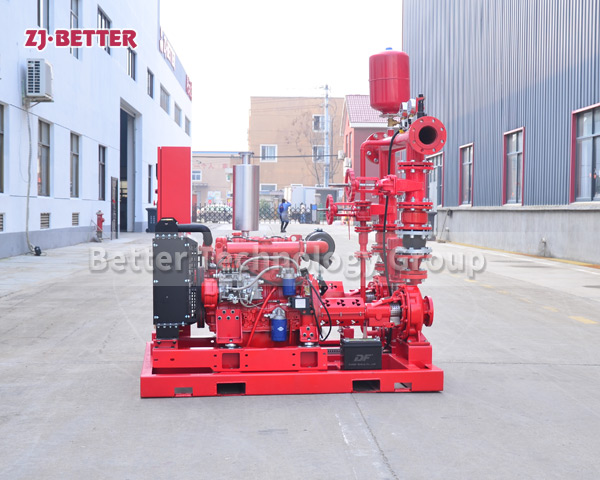

Fire-fighting pressure-stabilizing pumps achieve precise pressure regulation and high-efficiency operation through an intelligent control system. They have advantages such as automatic start-stop, energy saving and environmental protection, and stability and reliability. They are suitable for fire protection systems in high-rise buildings, industrial plants, underground garages, etc., and effectively ensure constant water pressure and emergency water supply safety.

As an indispensable component of modern fire protection systems, fire-fighting pressure-stabilizing pumps play a crucial role in maintaining stable system pipeline pressure and ensuring rapid emergency response. With the widespread application of intelligent control technology, the design concept of fire-fighting pressure-stabilizing pumps has shifted from traditional mechanical regulation to a deep integration of electronic automation and intelligent monitoring, resulting in significant improvements in efficiency, reliability, and energy consumption control. Intelligent control systems endow pressure-stabilizing pumps with higher sensitivity and accuracy, enabling them to respond instantly to pressure changes in complex fire-fighting environments, thus ensuring the entire fire pipeline network remains in an ideal operating state. One of the core advantages of modern fire-fighting pressure-stabilizing pumps lies in their high-precision pressure control capabilities. Through built-in intelligent sensors and electronic pressure feedback systems, the equipment can monitor system pressure changes in real time and automatically adjust the pump’s start-up and shutdown status to ensure that the pipeline water pressure remains within a preset range. When the pipeline pressure drops due to minor leaks or system evaporation, the pressure-stabilizing pump automatically starts to replenish pressure; and when the pressure reaches the set upper limit, the system automatically stops operating to avoid energy waste. This fully automated adjustment mode not only improves the stability of equipment operation but also reduces the frequency of manual intervention, significantly enhancing the overall reliability of the system. Compared to traditional pressure-stabilizing equipment, modern intelligent fire-fighting pressure-stabilizing pumps feature a more compact and rational structural design, with an overall modular layout that facilitates transportation, installation, and maintenance. Utilizing high-efficiency energy-saving motors and optimized impeller design, hydraulic efficiency is significantly improved, and mechanical energy loss is reduced, resulting in lower energy consumption and a longer service life. Simultaneously, all internal components undergo anti-corrosion, anti-rust, and high-temperature treatments to ensure excellent performance during long-term operation and in harsh environments. Whether under high humidity, dust, or high-temperature conditions, this type of equipment maintains stable output performance, effectively avoiding common problems in traditional pump sets such as mechanical wear, seal aging, and energy efficiency degradation. In terms of the control system, modern fire-fighting pressure-stabilizing pumps are equipped with an intelligent control panel and a microprocessor core logic unit, enabling comprehensive monitoring and data analysis of operating parameters. Operators can view system pressure, current, operating time, and fault records in real time through a digital display interface, achieving one-button start/stop and remote monitoring functions. Some high-end models also support linkage with the main fire pump control system and automatic alarm system, transmitting data in real time through a communication interface to achieve centralized management and intelligent scheduling. When the fire protection system is operational, the pressure-stabilizing pump automatically stops, allowing the main pump to take over the water supply. During system standby, the pressure-stabilizing pump automatically maintains pressure balance, achieving dual protection of main/standby coordination and energy optimization. Performance stability is a key design indicator for fire-fighting pressure-stabilizing pumps. Modern products utilize variable frequency control technology to dynamically match motor speed with pressure demand, effectively reducing energy loss while minimizing mechanical shock. Variable frequency technology also enables the system to automatically adjust its operating frequency under different operating conditions, ensuring pressure accuracy and extending equipment lifespan. Compared to traditional fixed-speed pumps, variable frequency pressure-stabilizing pumps offer smoother start-stop frequency control, avoiding damage to the motor and piping network caused by instantaneous current surges during startup. Furthermore, the equipment features multiple protection mechanisms, including overvoltage, undervoltage, overcurrent, phase loss, and dry-run protection. Upon detecting any abnormal condition, the system will automatically alarm and stop operation, effectively preventing damage or safety accidents. Fire-fighting pressure-stabilizing pumps have a wide range of applications, suitable for various fire protection systems requiring continuous pressure, such as high-rise buildings, factory workshops, underground parking lots, warehousing and logistics centers, and large complexes. In these environments, the pressure-stabilizing pump provides ideal starting conditions for the main pump by precisely controlling water pressure, preventing insufficient pipeline pressure from affecting the spraying effect of the fire extinguishing system. Especially at night or during off-peak hours, when system water consumption decreases, the pressure-stabilizing pump can maintain system static pressure with extremely low energy consumption, ensuring that the main fire pump can intervene in the shortest possible time in the event of a fire. Its high efficiency, low noise, and low energy consumption make it an ideal choice that balances energy saving and safety. In addition to its performance and functional advantages, modern fire-fighting pressure-stabilizing pumps also demonstrate intelligent and convenient maintenance and management. Their modular structure design makes maintenance and replacement of parts more convenient, and standardized interfaces ensure system compatibility and scalability. Some models also support IoT monitoring, allowing remote viewing of operating status and maintenance records through a cloud platform, achieving unattended full-cycle management. Leveraging intelligent algorithms, the system can automatically optimize operating strategies based on historical data, predict potential fault risks, and issue early warnings, thereby reducing downtime and improving equipment availability. This intelligent maintenance function not only reduces operating costs but also enhances the overall safety redundancy of the fire protection system. The energy-saving characteristics of the fire-fighting pressure-stabilizing pump are also a key aspect of its market competitiveness. Thanks to the combination of high-efficiency motors, fluid optimization design, and intelligent control strategies, the equipment effectively reduces energy consumption and carbon emissions during long-term operation, achieving green environmental protection goals. Especially in modern buildings with high energy efficiency requirements, the use of intelligent pressure-stabilizing pump systems can significantly reduce operating costs while conforming to sustainable development design principles. Furthermore, the equipment operates with low vibration and low noise, allowing for flexible installation in various environments without the need for additional sound insulation measures. With the continuous improvement of fire safety standards, intelligence and high reliability have become fundamental requirements for modern fire protection systems. The fire-fighting pressure-stabilizing pump, with its superior performance and intelligent management functions, is becoming the mainstream choice in the global fire protection industry. It not only plays a crucial role in ensuring the fire protection system is always ready for operation but also demonstrates strong advantages in energy consumption optimization, operational reliability, and system integration. For architects, fire protection engineers, and system integrators, choosing a high-performance fire pressure-stabilizing pump means choosing a stable, energy-efficient, and highly effective safety guarantee. It represents the future direction of fire protection technology—a highly efficient and safe system built upon intelligent control, precise pressure regulation, and reliable water supply.