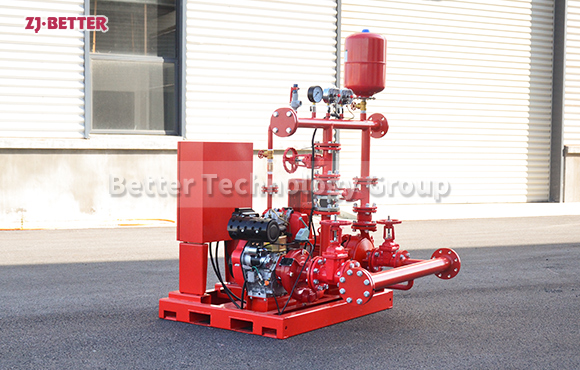

Inline Fire Pump System: Reliable Safety Solution for Factories, Warehouses, and Commercial Facilities

The pipeline pump fire protection system is designed specifically for factories, warehouses and commercial facilities. It has the advantages of compact structure, flexible installation, stable operation, energy saving and high efficiency. It can quickly provide high-pressure water source in fire to ensure fire safety. At the same time, it is easy to maintain and has a long service life. It is widely applicable to the fire protection needs of various modern buildings.

In modern society, the scale of factories, warehouses and commercial facilities continues to expand, the complexity of building structures increases, and the risk of fire also increases. Therefore, choosing an efficient, reliable and energy-saving fire water supply system has become the key to ensuring safety. Among them, the pipeline pump fire protection system is widely used due to its compact design, stable operation and superior performance. It can not only quickly provide high-pressure water source when a fire occurs to meet the needs of sprinkler systems, fire hydrant systems and other fire-fighting equipment, but also maintain efficient and energy-saving hydraulic transmission functions in daily operation, becoming an indispensable core equipment in the safety management of industrial and commercial buildings. The biggest advantage of the pipeline pump fire protection system is its compact structure. The pump body is coaxial with the motor, which is easy to install and can be directly connected to the pipeline system. It is particularly suitable for machine rooms with limited space or places that require complete installation. At the same time, the pipeline pump can be installed vertically or horizontally, with high flexibility. It can be arranged according to the design requirements of different buildings, thereby saving civil engineering and installation costs. This flexible installation feature is especially suitable for scenes such as factory workshops, storage and logistics centers, and commercial complexes, which effectively improves space utilization. In addition to its structural advantages, the pipeline pump fire protection system also performs well in performance. It adopts an efficient hydraulic model, which can achieve stable high head and large flow water supply at low energy consumption, ensuring that the fire is under control. Sufficient fire-fighting water can be provided at the early stage of a disaster, thus buying precious time for fire-fighting. In addition, the system’s water pump runs smoothly, with low noise and small vibration, which is not only conducive to extending the life of the equipment itself, but also reduces the impact on the surrounding environment. It is very suitable for commercial buildings and storage facilities with strict noise requirements. The pipeline pump fire-fighting system is equipped with an advanced automatic control cabinet, which can realize intelligent operation and monitoring. When the system detects a drop in water pressure, the water pump can automatically start and quickly replenish water to ensure that the pressure of the fire-fighting pipe network is always kept within a safe range. In an emergency, the control system can also realize manual and automatic switching to ensure the dual safety of the system. This automation and Intelligent control methods have greatly improved the reliability and response speed of the system, while also reducing the risks and workload of manual operations, making it an ideal choice for modern intelligent building management. The pipeline pump fire protection system also performs outstandingly in reliability design. It usually adopts a configuration mode that combines a main pump, a backup pump, and a pressure-stabilizing pump. When the main pump fails to operate due to a fault or maintenance, the backup pump will automatically start to operate to ensure continuous water supply to the system, while the pressure-stabilizing pump can maintain the pressure of the pipe network on a daily basis, avoiding frequent starting and stopping of the main pump, and improving the system life and operating efficiency. This multi-pump combination greatly enhances the redundancy and safety of the system, allowing factories, warehouses, and commercial facilities to operate even in complex There is also a stable fire protection in the environment. From the application scenario, there are usually a large number of flammable materials and high-temperature production equipment in the factory environment. Once a fire occurs, the fire spreads rapidly and the losses are huge. Therefore, the pipeline pump fire protection system is particularly important in the factory fire protection system. It can perfectly match the fire hydrant system and the automatic sprinkler system to ensure the provision of high-flow water sources at critical moments and support large-scale fire fighting needs. In warehouses and logistics centers, goods are densely stacked and there are many fire hazards. Especially when storing combustible materials such as paper, plastic, wood, and chemicals, the fire risk is extremely high. The pipeline pump fire protection system, with its stable water supply and long-term continuous operation capabilities, can effectively It provides strong support for warehouse fire protection and reduces fire losses. In large commercial facilities such as shopping malls, hotels, office buildings and other places, the pipeline pump fire protection system can not only ensure the water supply in emergency situations, but also because of its stable operation and low noise, it will not cause trouble to customers and staff in daily use, and truly achieves a balance between safety and comfort. In addition, the pipeline pump fire protection system also has the advantage of easy maintenance. Its modular design is easy to install and repair. Simple lubrication, cleaning and inspection are required to keep the system running stably. The pump body and key components are made of wear-resistant materials, with a long life and low maintenance cost, which is very suitable for long-term stability. It is undoubtedly an economical and efficient choice for factories and storage enterprises in operation. At the same time, the system also has strong energy-saving performance. It can reduce energy consumption without affecting the water supply effect, help enterprises save operating costs, and meet the requirements of green buildings and energy conservation and emission reduction. The pipeline pump fire protection system not only meets the fire protection needs of modern buildings in terms of performance and reliability, but also complies with relevant international and domestic standards. It can pass multiple certifications to ensure the quality and safety of the product. This standardized design enables it to be widely exported and suitable for engineering projects in different countries and regions. Whether in Asia, Europe or the Middle East, the pipeline pump fire protection system has been widely used and has become a global As an irreplaceable and important equipment in the fire protection system, in summary, the pipeline pump fire protection system has become the core equipment in the fire protection of factories, warehouses and commercial facilities with its multiple advantages such as compact structure, flexible installation, excellent performance, stable operation, intelligent control, redundant reliability and easy maintenance. It can not only provide fast, stable and efficient water supply guarantee when a fire occurs, but also demonstrate the characteristics of energy saving, environmental protection and economic efficiency in daily operation. For modern buildings that pursue safety, reliability and efficiency, the pipeline pump fire protection system is undoubtedly the best choice. While protecting the safety of life and property, it also brings a higher level of fire protection and operational benefits to enterprises and society.