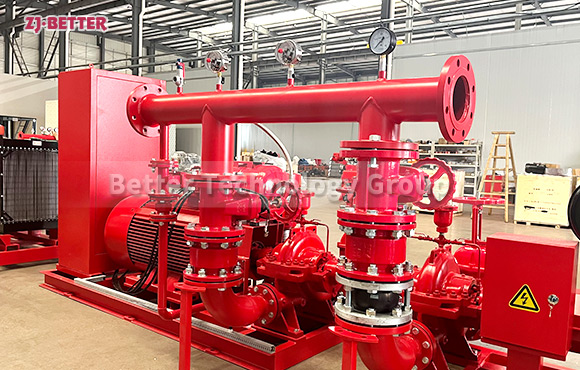

Vertical Fire Pump System for Industrial and Commercial Facilities – The Optimal Choice for Stability and Safety

Dual vertical fire pump units for industrial and commercial facilities offer efficient water supply, dual pump redundancy, automatic control, energy conservation and environmental protection. They safeguard fire safety in high-rise buildings, factories and commercial complexes, ensuring stable water supply and reliable operation during fire emergencies.

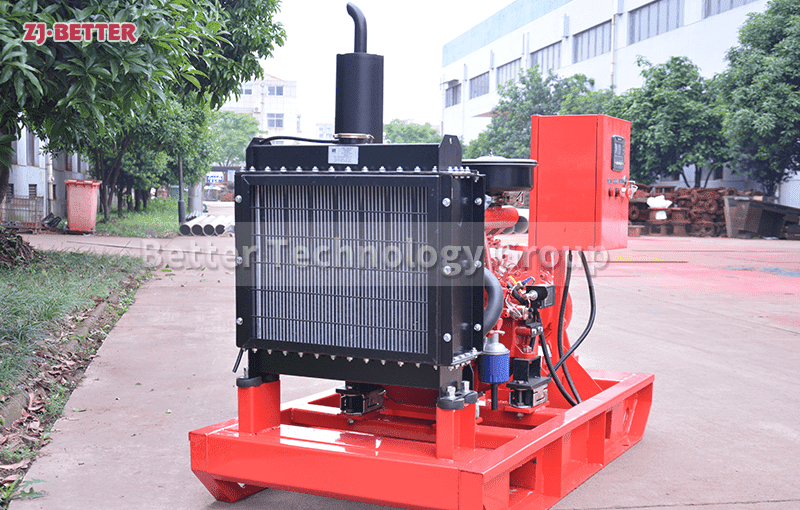

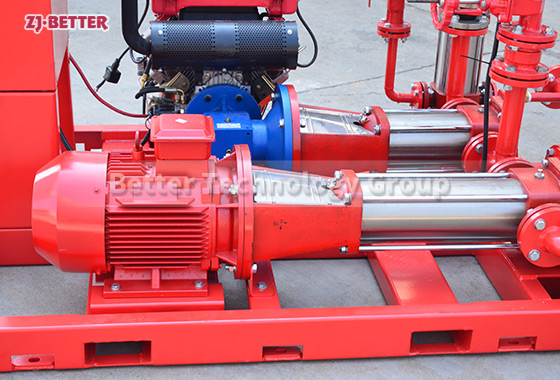

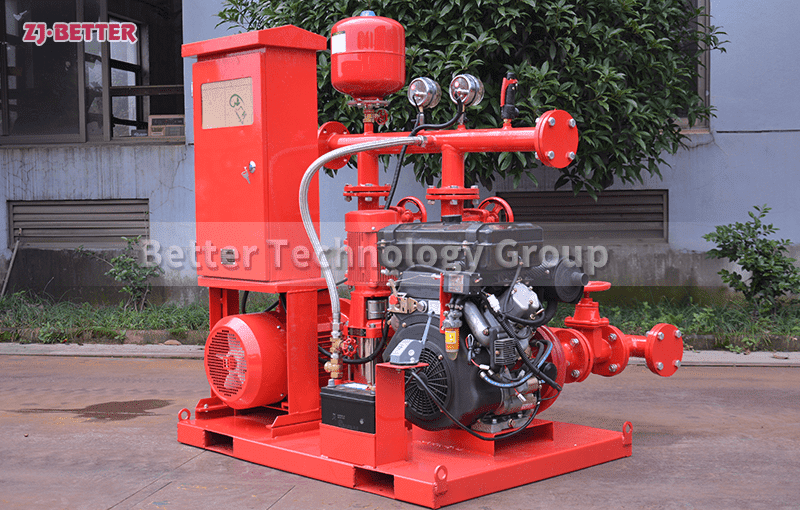

In modern society, with the continuous expansion and upgrading of industrial and commercial facilities, the construction of fire protection systems has been elevated to an unprecedented level of importance. As a core component, fire pumps directly determine whether the fire protection system can operate efficiently and stably at critical moments. As a high-performance water supply equipment developed to meet the complex needs of large-scale industrial and commercial facilities, the dual vertical fire pump unit has gradually become the preferred equipment for high-rise buildings, industrial plants, large storage centers, and commercial complexes due to its reasonable structure, stable operation, long-term water supply, and intelligent management. As the name suggests, the dual vertical fire pump unit consists of two vertical pump bodies. By operating in parallel or alternating mode, it not only greatly improves the overall reliability of the system, but also allows it to maintain sufficient water supply capacity in the event of sudden fires and high-demand conditions. This equipment features a dual-pump configuration, enhancing redundancy. If one pump is temporarily shut down due to failure or maintenance, the other pump can immediately take over, ensuring continuous water supply. It also allows for simultaneous operation of both pumps to meet sudden surges in water demand. Fires in large shopping malls, logistics warehouses, chemical plants, or high-rise buildings often require enormous amounts of water. Dual vertical fire pump units ensure rapid delivery of sufficient water flow and stable pressure, enabling rapid fire control and saving valuable rescue time. Dual vertical fire pump units offer significant structural advantages. Their vertical layout occupies a small footprint, making them suitable for installation in limited space in machine rooms or basements, even within large commercial buildings in urban cores where space is at a premium. Furthermore, the vertical pump design ensures smoother water flow and higher hydraulic efficiency, minimizing water losses and further improving overall efficiency. The pump body is constructed of high-strength cast iron or alloy steel, offering excellent pressure and corrosion resistance. It operates stably and reliably under diverse water conditions, is less susceptible to leaks and damage, and reduces maintenance costs. The motor is equipped with a highly efficient and energy-saving drive system, ensuring strong power output while effectively reducing energy consumption. This is a significant cost savings for industrial and commercial facilities with long operating times and high loads. In terms of performance, the twin-vertical fire pump unit is capable of long-term stable operation under high-pressure and high-flow operating conditions. The pump’s rated flow rate and head can be flexibly configured to meet project requirements, providing strong adaptability. To meet the stringent standards of modern building fire protection systems, the unit can be linked with an automatic control system for fully automatic start and stop, intelligent switching, and real-time monitoring. When the fire alarm system issues a signal, the pump unit automatically starts in a fraction of a second and automatically adjusts its operating mode based on water usage, enabling efficient, unattended operation. During routine maintenance, data can be read and operational status analyzed via the control cabinet panel or remote monitoring platform, allowing management personnel to monitor equipment operation status. Compared to traditional single-pump systems, the twin-vertical fire pump unit offers a significant improvement in safety. The dual-pump backup feature effectively eliminates the risk of system failure due to a single pump failure, significantly improving the reliability of the fire water supply system. Furthermore, the alternating operation of the two pumps ensures long-term stable system operation while extending equipment life and preventing excessive wear and tear caused by prolonged, continuous operation of a single pump. The equipment operates with low noise and vibration, meeting modern green environmental standards and integrating seamlessly into the operational environments of commercial and industrial facilities without causing excessive disruption to personnel or the surrounding environment. Dual-vertical fire pump units are widely used in a variety of applications, including high-rise buildings, commercial complexes, hospitals, schools, factory floors, petrochemical bases, and large-scale logistics and storage centers. In these locations, firefighting systems must be able to provide an immediate and continuous supply of water. Dual-vertical fire pump units, with their robust water supply performance and high reliability, ensure smooth firefighting operations and minimize fire damage. Dual-vertical fire pump units, with their robust performance and high reliability, are particularly important in specialized industries such as petrochemicals, pharmaceuticals, and energy, where fire hazards are significant and fire protection requirements are more stringent. Their robust performance makes them indispensable safety equipment. From a long-term investment perspective, choosing a dual-vertical fire pump unit is not just about purchasing the equipment itself, but also about improving the fire safety of the entire facility. Due to their high efficiency and low energy consumption, these pump sets significantly save energy costs and reduce carbon emissions during operation, aligning with current trends in green energy conservation and sustainable development. Furthermore, their low failure rate and simplified maintenance reduce operational expenses, enabling users to achieve higher economic benefits while ensuring fire safety. Notably, these pump sets are also extremely convenient to install and commission. The pump sets are typically delivered as a complete set, requiring only piping and electrical connections according to the design drawings. This significantly shortens the installation cycle and reduces construction complexity. The user-friendly control cabinet design and intuitive user interface allow administrators to easily operate without extensive training, reducing management costs. With the increasing adoption of smart fire protection, dual-vertical fire pump sets also enable remote monitoring and control through the Internet of Things (IoT). Administrators can monitor pump operating data in real time via mobile phones or computers, receive timely fault alarm notifications, and remotely start and stop the pump set when necessary. This feature not only enhances the intelligence of the equipment but also allows users to more easily navigate the complexities of fire safety management. In summary, the dual-vertical fire pump unit for industrial and commercial facilities, with its efficient and stable water supply performance, flexible configuration, intelligent control system, and excellent energy-saving and environmental protection features, has become an ideal choice for the construction of fire protection systems in modern large-scale buildings and industrial facilities. It not only represents advanced firefighting technology but also serves as a vital barrier to protect life and property. It provides users with an efficient, reliable, and intelligent fire water supply solution and will continue to play an irreplaceable and important role in future fire safety construction.