Working of Diesel Engine Fire Pump in Low Temperature Environment

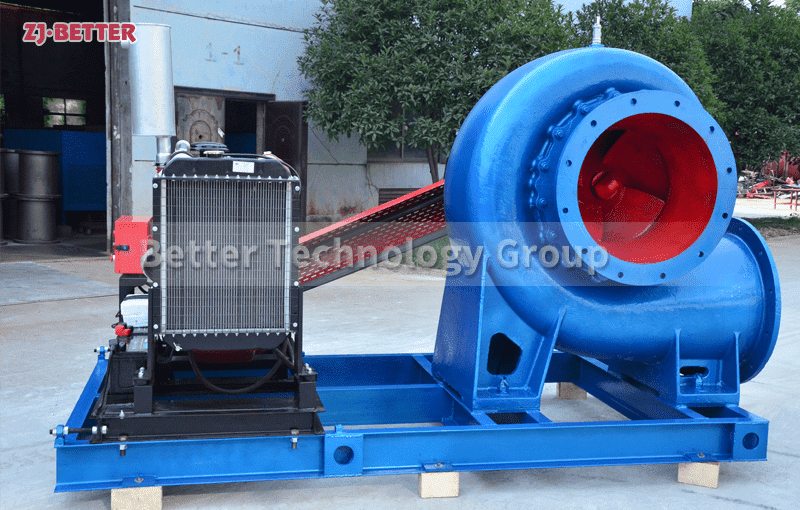

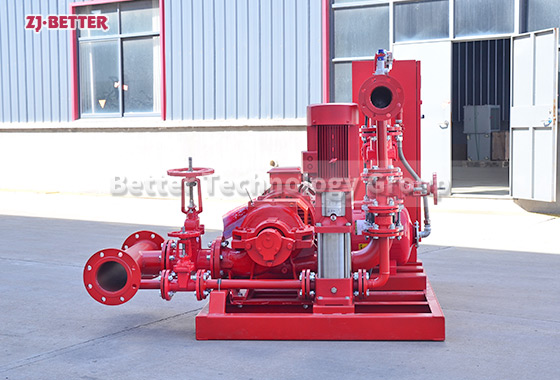

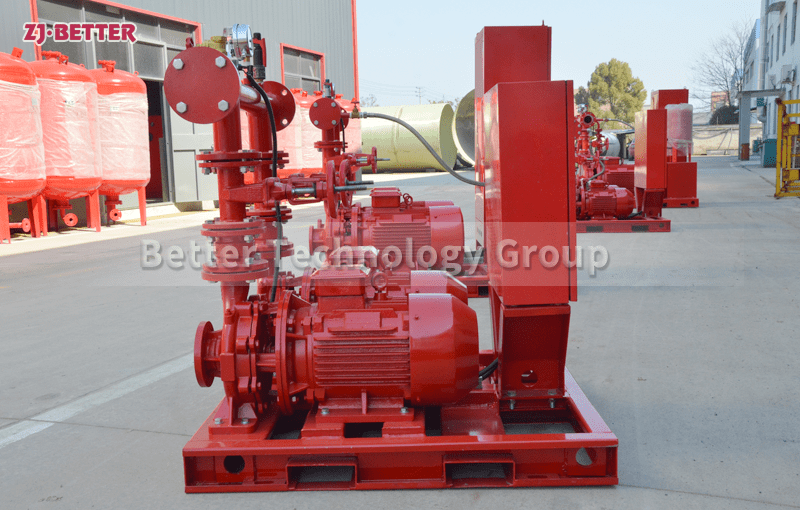

Diesel engine fire pumps are widely used in firefighting equipment due to their various advantages. Most firefighting equipment will choose to use this equipment, which has various automation functions and can be connected with other equipment according to customer needs. It is a kind of equipment with good starting characteristics, strong overload capacity, compact structure, convenient maintenance, simple use, and a high degree of automation.

Diesel engine fire pumps are widely used in firefighting equipment due to their various advantages. Most firefighting equipment will choose to use this equipment, which has various automation functions and can be connected with other equipment according to customer needs. It is a kind of equipment with good starting characteristics, strong overload capacity, compact structure, convenient maintenance, simple use, and a high degree of automation.