Stable performance of diesel engine fire pump

With the continuous development of society, people have higher requirements for the quality of life, and the safety of diesel engine fire pumps is more important. All places need to be equipped with fire-fighting facilities, and fire pumps are water intake equipment for fire-fighting facilities. The fire pumps we commonly use are electric fire pumps and diesel engine fire pumps. The difference between them is that electric fire pumps need power system supply. In case of power failure, the diesel engine fire pump can be started at any time to make up for the original position of the electric fire pump.

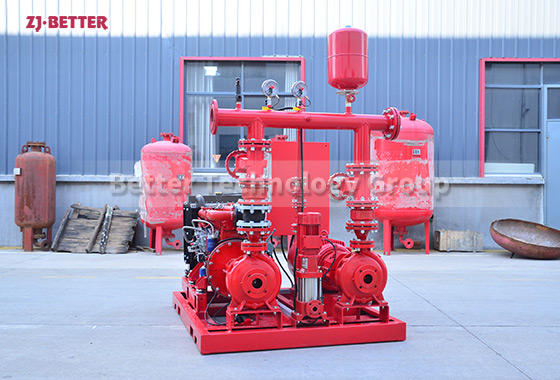

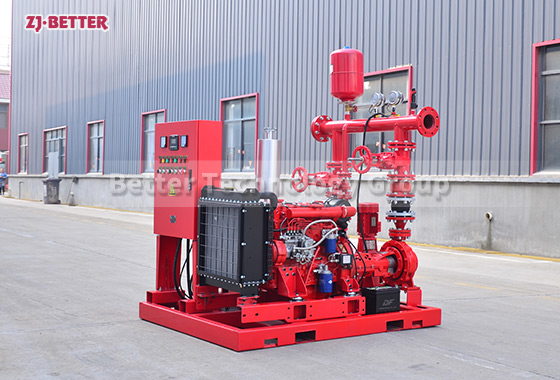

The diesel engine fire pump is aimed at fire water supply for large flow and high head occasions, and the diesel engine has good starting characteristics, fast starting speed, strong overload capacity, energy saving and does not need to be in standby all the time. The fire pump has complete performance and wide spectrum range. Single-stage single-suction pumps, multi-stage single-suction pumps and self-priming pumps can also be used in parallel combination, with large flow and pressure ranges. Fire pumps are widely used for fire water supply in warehouses, docks, airports, petrochemical, power plants and other industrial and mining enterprises. The flow rate and head are relatively large, and the temperature of the conveying medium can reach 80°C.

The diesel engine fire pump can be matched with different brands of diesel engines, which can ensure the stable performance of the diesel engine fire pump, long service life and high degree of automation. If you have other questions or puzzles about diesel engine fire pumps, we welcome your inquiries and look forward to cooperating with you.