What Are the Energy-Saving and Reliability Advantages of Diesel Fire Pumps Compared to Traditional Fire Pumps?

Better Technology’s diesel fire pump integrates a high-performance diesel engine with an efficient fire pump, delivering stable and powerful water flow in emergencies. Its independent power supply ensures reliable operation even in power outages, making it ideal for industrial, commercial, and remote fire protection. Designed with a smart control system, it enables automatic start-stop for rapid emergency response. Built to UL and NFPA standards, it offers reliable global fire safety solutions.

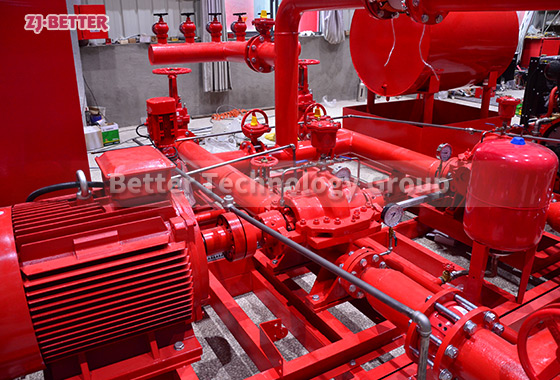

The company specializes in the research and manufacturing of high-quality fire pumps, offering a wide range of products, including electric fire pumps, diesel fire pumps, pressure-stabilizing water supply systems, and complete fire pump sets. These products are widely used in industries, commercial buildings, high-rise structures, and municipal projects. All products meet international fire protection standards such as UL, NFPA, and CCCf, ensuring superior performance and safety.

Committed to delivering efficient, energy-saving, and durable fire protection solutions, the company integrates advanced manufacturing technology and intelligent control systems to ensure rapid response and stable operation in emergencies. With extensive industry experience and a rigorous quality management system, its products are exported to numerous countries and regions, providing a reliable foundation for global fire safety.