Combining Robust Water Pressure and Smart Controls for Efficient Firefighting

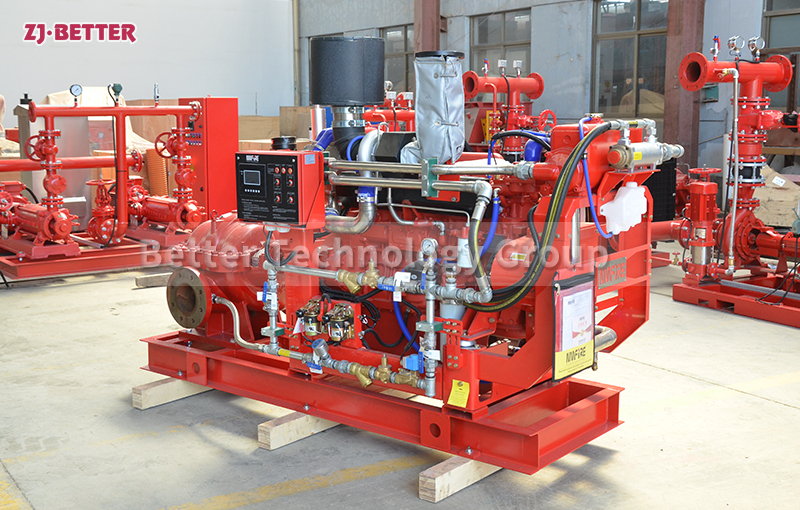

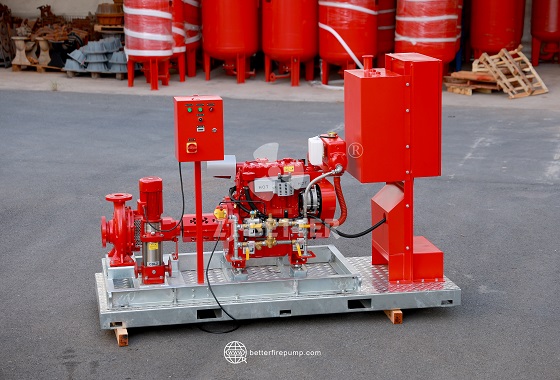

This fire pump system features an advanced, high-efficiency pump design that delivers a high flow rate and elevated water pressure, ensuring that adequate water supply is available to quickly control fires in their early stages. Integrated with an intelligent control module, the system monitors real-time operating conditions, automatically adjusts working parameters, and promptly issues alarms in case of any abnormalities, keeping the system operating optimally at all times. By combining robust water pressure with precise smart monitoring, this system not only achieves outstanding firefighting effectiveness but also reduces energy consumption and extends equipment lifespan. It is an ideal solution for providing reliable fire protection across various industrial, commercial, and public buildings.

Leveraging years of technical expertise and continuous innovation, this enterprise is dedicated to the research, development, and manufacturing of high-efficiency fire pump systems aimed at comprehensively upgrading emergency water supply solutions. From advanced integrated control cabinets to state-of-the-art electric and diesel pump sets, the company consistently introduces fire protection equipment tailored to diverse application needs. Its product designs incorporate the latest automation technology and energy-saving principles, ensuring the delivery of stable high-pressure water flow in complex environments to meet the rigorous requirements of high-rise buildings, industrial parks, and municipal facilities. With stringent quality control and ongoing process optimization, the equipment always complies with international safety standards and delivers outstanding performance in critical sectors. Driven by customer-centric innovation and breakthroughs, the enterprise is leading the advancement of fire safety technology, providing robust support for building secure, reliable, and environmentally friendly fire protection systems worldwide.