The Core Role of Enclosed Fire Pump Units in Unattended Fire Protection Systems

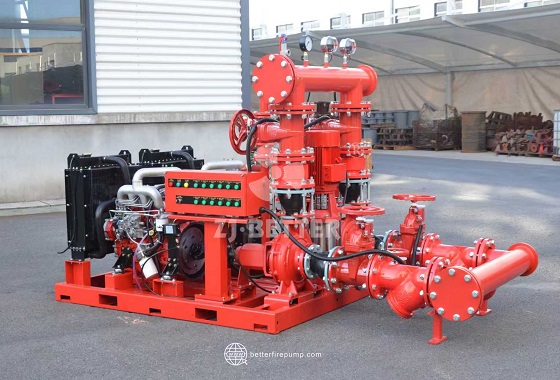

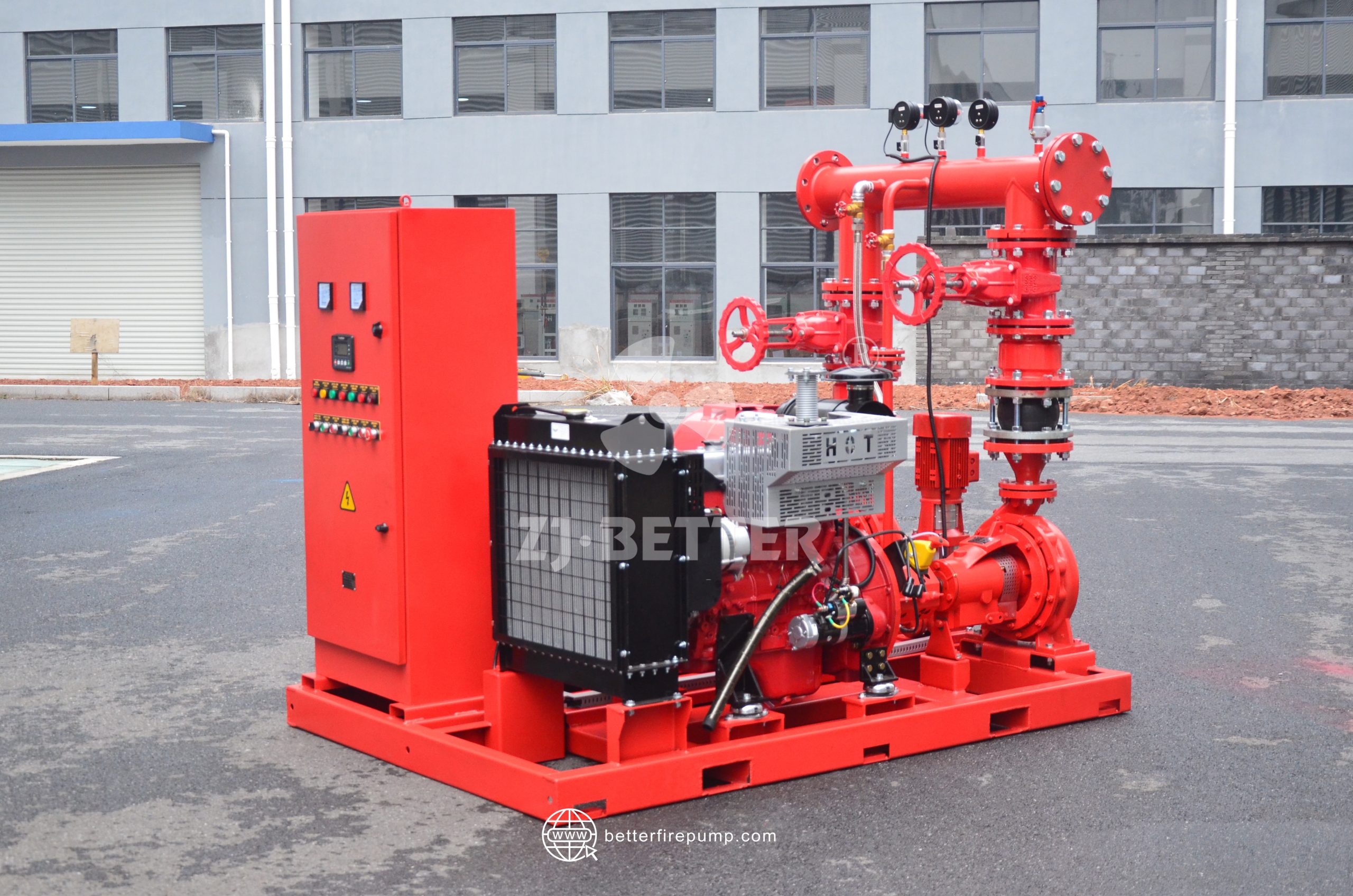

The box-type fire pump unit is suitable for unattended fire protection systems. It adopts an integrated box design, has good protection performance and stable operation capability, supports automatic start and remote monitoring, and ensures rapid water supply and continuous and reliable fire protection in the event of a fire.

The core role of enclosed fire pump units in unattended fire protection systems lies primarily in their highly integrated design, stable and reliable operation, and comprehensive support for the automation and safety of modern fire protection systems. These devices typically employ a fully enclosed enclosure structure, integrating the fire pump, power system, control system, piping components, and necessary monitoring and protection devices within a steel or composite material enclosure. This fundamentally solves the problems faced by traditional open-type fire pumps in unattended scenarios, such as poor environmental adaptability, insufficient operational reliability, and high maintenance and management difficulties. In unattended fire protection systems, equipment is often installed in underground pump rooms, outdoor open spaces, factory edges, or locations far from areas of human activity. This places extremely high demands on the environmental protection capabilities of the fire pump units. Enclosed fire pump units, through their overall sealed structure design, effectively isolate rainwater, dust, sand, corrosive gases, and insects and small animals from intrusion, ensuring that critical internal components remain in a stable and controllable working environment for extended periods, thereby significantly reducing the probability of failure caused by external factors. The internal enclosure typically features a well-designed ventilation and heat dissipation system, maintaining good heat dissipation efficiency while ensuring protection levels. This allows the power system to maintain stable output even under prolonged standby or sudden high-load operation conditions, which is crucial for rapid response in the early stages of a fire in unattended fire protection systems. These fire pump units emphasize reliable start-up and continuous water supply. The power system can be matched with motors or other power sources according to project requirements. Through optimized transmission structures and efficient hydraulic design, it ensures the rapid establishment of stable pressure and flow under rated operating conditions. Even after prolonged periods of inactivity, it can quickly commence operation upon receiving a start signal, avoiding missed opportunities for optimal fire suppression due to start-up failure. Enclosed fire pump units are usually equipped with intelligent control systems, supporting automatic start-up, automatic switching, remote monitoring, and fault alarm functions. This allows for seamless integration into the overall control logic of unattended fire protection systems. When pipeline pressure drops or a fire signal is triggered, the equipment can complete start-up, operation, and status feedback without manual intervention, truly achieving 24/7 standby. The control system utilizes industrial-grade components and employs optimized wiring and protection designs to enhance anti-interference capabilities and operational stability, ensuring reliable operation even under voltage fluctuations or complex electromagnetic environments. The enclosure structure also facilitates equipment maintenance and management, with a rational internal space layout and clear functional module partitions. Even in unattended systems, potential problems can be quickly located through regular inspections or remote diagnostics, reducing on-site maintenance time and labor costs. Regarding materials and manufacturing processes, enclosure-type fire pump units typically use high-strength steel or weather-resistant materials, and undergo anti-corrosion and rust-proofing treatments. This makes them suitable for environments with high humidity, high salt spray, or significant temperature variations, extending the overall service life. From a long-term operational perspective, this high-durability design significantly reduces total lifecycle costs. For unattended fire protection systems, long-term stability is more important than initial performance, and enclosure-type fire pump units meet this core requirement through comprehensive optimization of structure, protection, control, and performance. Furthermore, this type of equipment offers significant advantages in installation and deployment. It is shipped as a complete set, requiring only foundation fixing, power supply, and piping connections on-site before it can be put into use. This greatly shortens the construction cycle and reduces project complexity, which is particularly important for projects with tight schedules or limited construction conditions. In practical applications, box-type fire pump units are widely used in industrial plants, logistics warehouses, energy facilities, transportation hubs, and various infrastructure projects. Their performance in unattended fire protection systems demonstrates their irreplaceable role in ensuring continuous fire water supply and system reliability. By integrating high-efficiency pump units, intelligent control, and a robust enclosure, this type of fire pump equipment not only enhances the system’s safety level but also provides a solid hardware foundation for the automation and intelligent development of modern fire protection engineering. With the increasing trend towards unmanned management in the future, its application value and market prospects will continue to expand.