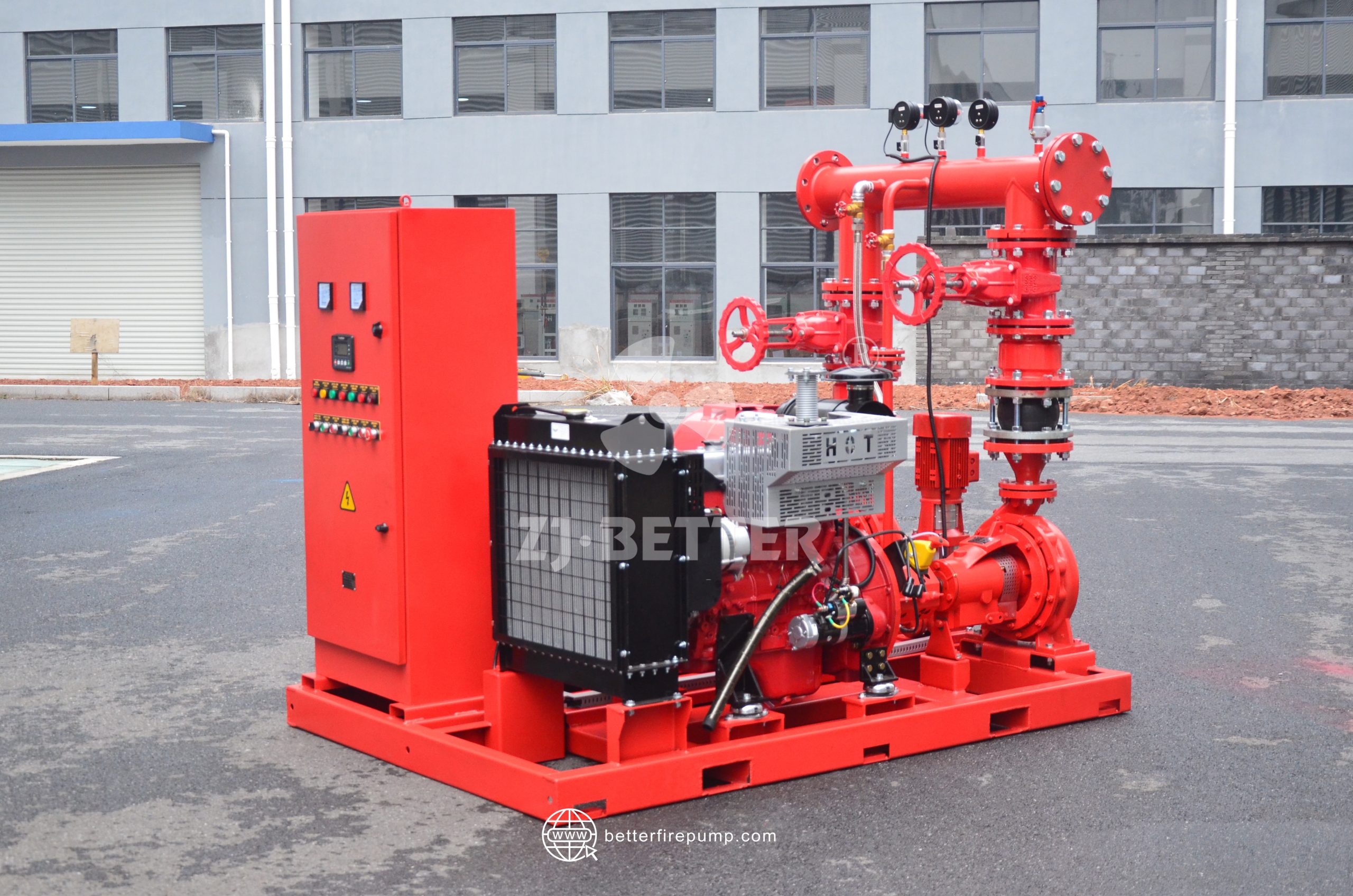

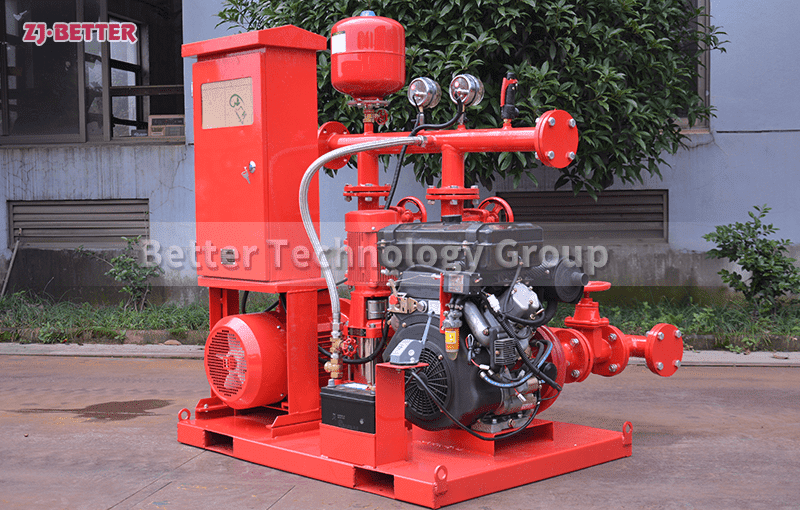

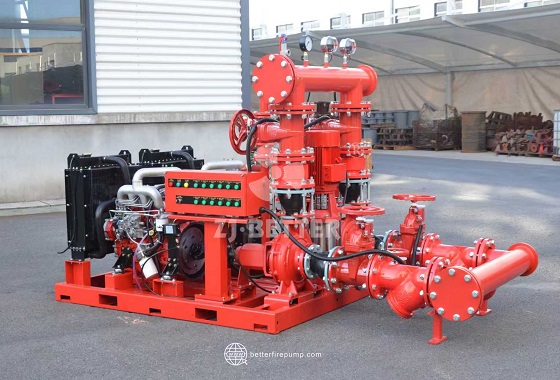

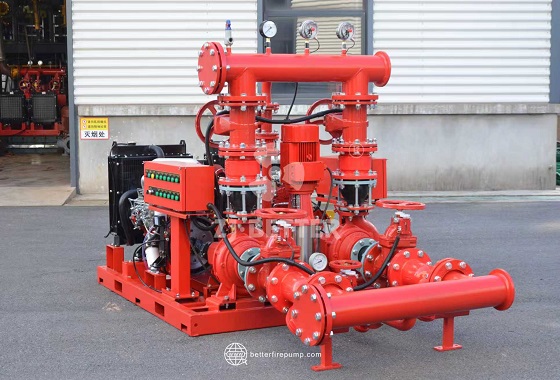

Fire Pump Package with Advanced Control Panel: Easy Operation and Fault Monitoring

Advanced control panel fire pump units achieve efficient, stable, and safe water supply through intelligent monitoring, automatic start/stop, and fault diagnosis functions. They are suitable for industrial facilities, high-rise buildings, and areas without electricity, providing a reliable power solution for emergency fire extinguishing systems.

Fire pump units equipped with advanced control panels are indispensable core equipment in modern fire protection systems. Their design philosophy revolves around rapid response, stable water supply, and intelligent control. By integrating mechanical power and electronic control technologies, they achieve comprehensive performance characterized by high efficiency, low failure rate, ease of management, and long-term reliable operation. These units consist of a power source, fire pump, water piping system, control panel, sensors, electrical modules, and safety protection mechanisms. They can be independently deployed in industrial facilities, high-rise buildings, municipal infrastructure, energy stations, airports, warehouses, petrochemical areas, and remote areas without electricity, ensuring a stable water pressure and sufficient flow rate in the event of a fire. The advanced control panel represents a technological leap compared to traditional manual control methods, enabling digital display and parameter adjustment. The system features temperature monitoring, operational status monitoring, and fault alerts, simplifying and automating the operation process and significantly reducing the risk of human error. Its core advantage lies in its automated start-stop mechanism. When pipeline pressure drops or a start command is triggered, the control panel quickly identifies the need and completes the startup procedure, enabling the fire pump to enter efficient operation within seconds. Simultaneously, the control system monitors speed, pressure, water flow, oil temperature, power status, power supply status, and pump vibration in real time. Any abnormalities will trigger an automatic alarm or even a shutdown protection mechanism. Compared to traditional fire pump units, the digital control system also supports parameter recording and data tracking, facilitating maintenance personnel’s analysis of usage habits and prediction of maintenance cycles. This intelligent recording capability shifts equipment management from passive repair to proactive maintenance, further extending equipment lifespan. The advanced control panel features a highly user-friendly design with a logical interface layout, clearly defined button functions, zoned indicator lights, and a clear LCD screen image, ensuring normal observation even in low light or outdoor conditions. The system possesses automatic diagnostic capabilities, simulating operating conditions and checking the status of wiring, sensors, power starting mechanisms, oil systems, and pump terminals. This ensures that the system will not fail due to potential defects when truly needed for startup. The control system also has a remote monitoring interface, uploading operating signals to the fire control center via a communication module or fire alarm linkage system. This allows management personnel to check the pump unit’s status from the fire control room or cloud platform, including whether it is in standby, operating, or maintenance mode. This remote capability is particularly important for large facilities, as it reduces the burden of manual inspections and improves response speed. The pump unit’s self-check process during startup includes procedures such as battery system testing, oil pressure confirmation, water pressure identification, and electronic unit diagnostics. Ignition or startup is only permitted after all procedures pass. This logic ensures that the unit maintains optimal condition even after prolonged periods without startup. The pump sets equipped with advanced control panels are generally diesel-powered and can operate independently when the mains power is interrupted, without the need for an external power supply. They are particularly suitable for remote sites, oil fields, airports, and areas with unstable power. The mechanical parts of the system use wear-resistant materials, precision machining, and fluid optimization design to achieve high pressure, high flow, and low vibration output. The pump body sealing system can effectively prevent leakage and cavitation, thereby extending the pump’s service life. The power unit has rapid response characteristics, enabling the unit to quickly enter working condition after a fire alarm is triggered or the pressure drops. This power matching combined with the intelligent panel makes the entire unit operate extremely efficiently. Another prominent feature of the advanced control panel is its dual local and remote control capability. This means that it can be switched when on-site operators need to intervene manually, while the unit can still be automatically monitored under normal circumstances. The system has built-in pressure switches, water flow monitoring devices, and fault logic processing modules to ensure that the unit does not operate under incorrect conditions. At the same time, the fault code display mechanism helps personnel quickly locate the cause of the problem, such as low oil pressure, water flow obstruction, start-up failure, or sensor malfunction, which significantly shortens maintenance time. In addition, the optional dual-pump or multi-pump system supports the control panel to operate multiple units in a coordinated manner, starting and stopping each pump as needed, rotating modes, or automatically switching between main and standby pumps under different flow and pressure demand scenarios to maintain continuous water supply capacity and prevent overload. The ease of system installation is also a significant advantage. The advanced control panel is integrated with the pump unit and fixed to the base, forming a complete integrated unit solution, reducing on-site wiring complexity. The panel has pre-set control logic and can be customized according to project parameters, such as setting operating pressure, automatic shutdown conditions, and pump switching modes. It is suitable for various environments including factory fire protection systems, commercial building water supply stations, oil and gas storage areas, fire tanks, and rooftop pump rooms. Due to its enclosed or semi-enclosed structural design, the control panel is dustproof, rainproof, and shockproof, making it suitable for outdoor deployment. Furthermore, the advanced control panel can store operating records and export data via an interface for use by the technical team. This data includes start-up counts, runtime, pump end pressure curves, fuel consumption rates, alarm history, and other information, which is valuable for subsequent system optimization and operational diagnostics. The flexible maintenance reminder function informs users when to replace filters, check oil lines, or adjust pump end lubrication devices to maintain efficient system operation. Overall, fire pump units equipped with advanced control panels represent the development trend of intelligent fire protection equipment. They integrate digital control, mechanical power, hydraulic engineering, and system safety concepts. Through sophisticated control logic and real-time monitoring capabilities, they make fire pump operation more reliable, worry-free, and safe. Any building or facility needs reliable fire water supply as soon as a fire breaks out, and intelligent control panels ensure that this capability is implemented. They not only improve equipment management efficiency but also reduce operating costs, enabling fire protection systems to leap from the traditional model to the digital and intelligent era. With the increase in urbanization, intelligent buildings, and major industrial facilities, the demand for advanced control pump units will continue to grow. This equipment has become an important emergency infrastructure for petrochemical plants, large logistics warehouses, airports, ports, municipal water supply systems, residential communities, data centers, and energy sites. In the future, with further improvements in control logic, remote linkage, and software diagnostic capabilities, intelligent fire pump systems will play an even more critical role in the safety industry, becoming an irreplaceable force in professional fire protection.

.jpg)