What are the key considerations for fire pumps in industrial manufacturing plants?

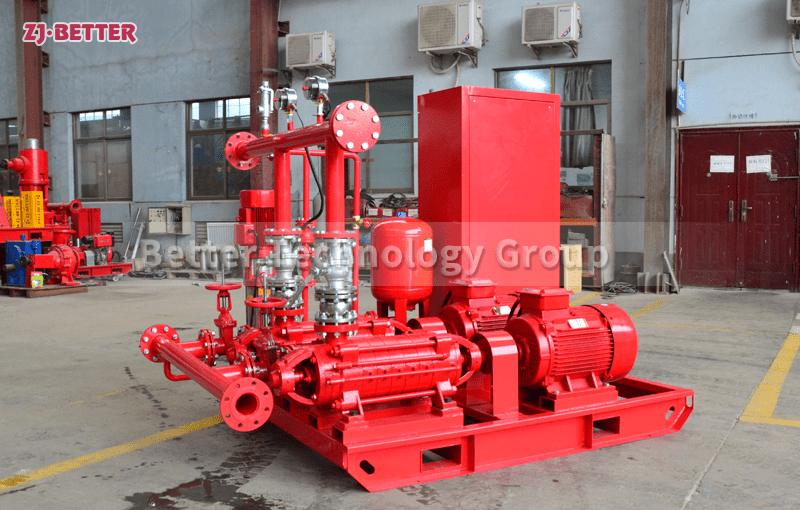

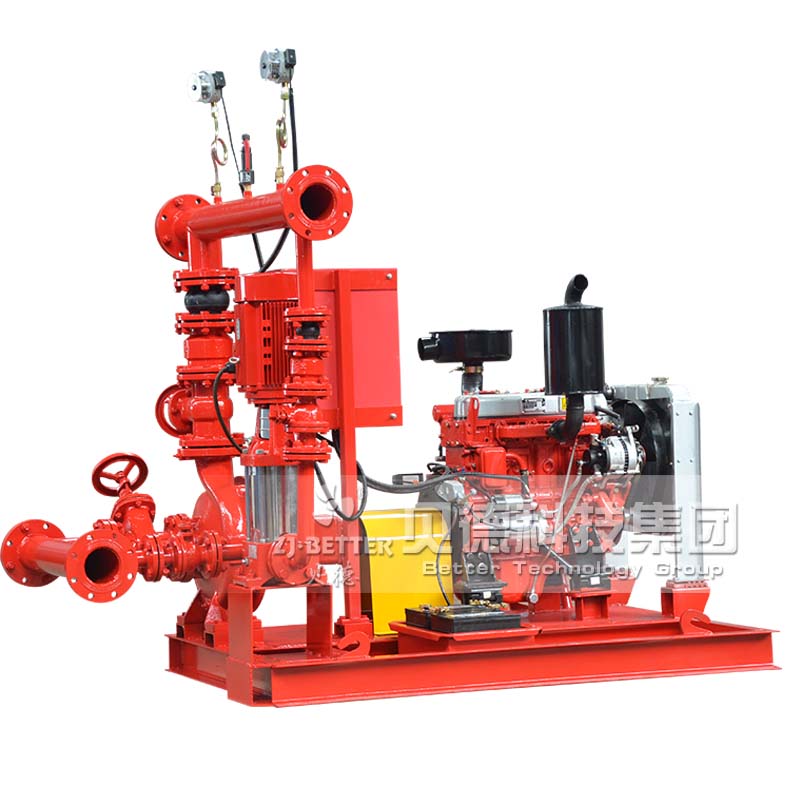

Industrial manufacturing plants often deal with hazardous materials, heavy machinery, and complex processes, making fire safety a critical concern. Fire pumps are essential in these facilities for delivering sufficient water pressure to fire suppression systems like sprinklers, standpipes, and specialized suppression systems, such as foam or gas-based systems used for chemical fires. Jockey pumps help maintain pressure in these extensive systems, ensuring they are always ready to activate immediately. In many industrial plants, fire pumps need to handle large volumes of water to cover expansive areas like production floors, storage facilities, and hazardous material zones. Additionally, fire suppression systems must be designed to address specific risks, such as oil-based fires, electrical hazards, or flammable chemicals. Fire pumps in these environments require regular maintenance and testing to ensure they remain reliable, especially given the high risk of equipment malfunction or accidents in such settings. Integrating the fire pump system with automated fire detection systems, alarms, and emergency response protocols is critical for minimizing damage and protecting workers in the event of a fire.