Smart Monitoring and Remote Control: The Next-Gen Diesel Fire Pump Technology Trends

Discover the advanced features of next-generation diesel fire pumps with intelligent monitoring and remote control capabilities. Ensure reliable fire protection with real-time data, automatic alerts, and remote operation for industrial and commercial applications.

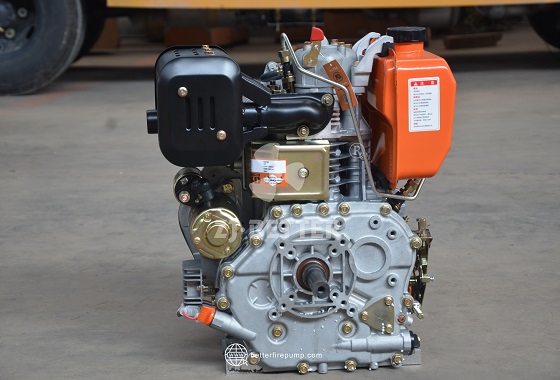

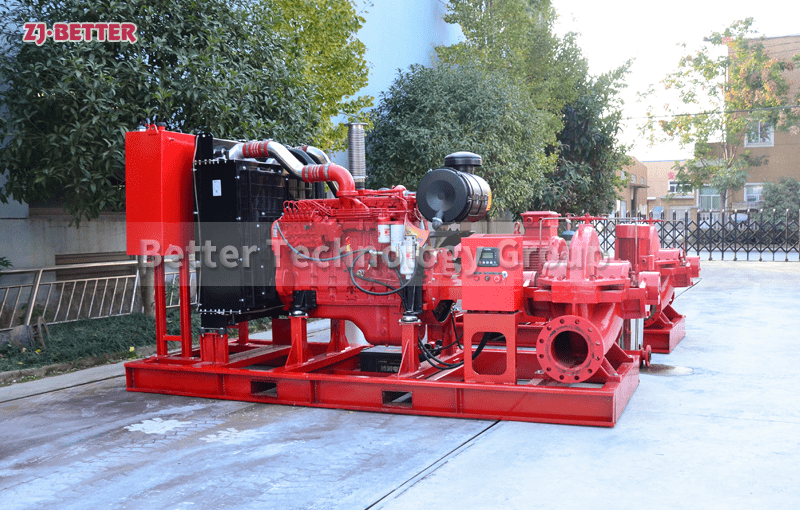

The evolution of fire protection systems has brought about significant advancements in diesel fire pump technologies, especially in the domains of intelligent monitoring and remote control. In modern fire safety engineering, the need for reliable, autonomous, and intelligent diesel-driven fire pump systems has become more essential than ever, particularly in large-scale facilities, industrial zones, high-rise buildings, data centers, chemical plants, and infrastructure projects where real-time responsiveness and high-efficiency operation are critical. This new generation of diesel fire pump systems is designed not only for robust fire suppression performance but also for intelligent operation management, offering real-time insights, diagnostics, and control that align with the ever-growing demands of smart infrastructure. One of the core advantages of modern diesel fire pump systems is their integration with intelligent monitoring modules. These modules include a wide array of sensors and digital interfaces that continuously track operational status parameters such as pump speed, engine temperature, oil pressure, fuel level, battery voltage, water flow, outlet pressure, suction pressure, and coolant temperature. This real-time data acquisition allows for proactive maintenance scheduling, early detection of anomalies, and detailed reporting of every operational cycle. The digital control panel, often featuring a high-resolution LCD or touchscreen, acts as the command center, providing both manual and automatic control capabilities. These panels are embedded with microcontrollers and programmable logic controllers (PLCs) that ensure immediate and accurate system response to fire alarm triggers or pipeline pressure drops. What sets these systems apart is the ability to connect with centralized Building Management Systems (BMS) or SCADA platforms via Modbus RTU, TCP/IP, or 4G/5G wireless protocols. This seamless connectivity allows facility managers or emergency personnel to monitor pump activity remotely through computers, tablets, or even smartphones. In the event of a fire emergency, remote start and stop functionality ensures that the pump can be activated even if local access is hindered, making it ideal for unmanned stations or facilities operating during off-hours. Additionally, the ability to generate automatic alarms, send SMS or email notifications, and maintain operational logs in the cloud significantly enhances incident transparency and post-event analysis. Performance-wise, these diesel fire pumps are powered by high-torque diesel engines that comply with international emission standards while delivering continuous-duty reliability. Their mechanical robustness is matched by hydraulic performance efficiency, often capable of achieving heads over 150 meters and flows exceeding 1000 GPM, depending on application requirements. Coupled with precision-cast impellers and wear-resistant materials, the pump heads are designed for long service life under harsh conditions. Another key innovation in this generation of diesel fire pump systems is the enhanced safety interlock design. Advanced logic control algorithms prevent common failure modes such as dry running, over-speed, low oil pressure, over-temperature, or reverse rotation. Redundant starting mechanisms, such as dual battery groups or compressed air starting options, further improve system reliability in high-risk environments. Moreover, these systems often come with auxiliary fuel tanks with level monitoring, dual cooling circuits (air and water cooled), vibration dampening mounts, and integrated exhaust systems that meet noise and emission control standards. The use of quick-connect ports and modular skid bases ensures fast deployment and minimal onsite installation time, especially in emergency retrofit scenarios. From a maintenance standpoint, the remote diagnostic capabilities significantly reduce downtime by allowing technicians to remotely assess system health before physically intervening. Maintenance alerts can be set based on runtime hours or operational cycles, improving predictive maintenance efficiency and reducing the total cost of ownership over the life cycle of the pump system. Integration with fire alarm panels and automatic sprinkler systems via voltage-free contacts or digital I/O ports enhances system interactivity. In complex fire protection networks, diesel fire pumps can be configured as lead or backup units in parallel with electric pumps, with automatic switchover capabilities in case of electrical failure. This redundant architecture ensures a higher level of safety and continuity, crucial in mission-critical environments such as hospitals, airports, power plants, and water treatment facilities. The smart diesel fire pump system also supports user-defined operating logic. For example, customized startup sequences, idle running for lubrication, scheduled testing routines, or sequential pump engagement based on real-time demand. The human-machine interface (HMI) allows for multiple language displays, graphical trends, and alarm history, empowering users to manage the system with confidence and clarity. Environmental resilience is another major benefit. These systems are engineered to operate reliably across extreme conditions — from desert heat and coastal humidity to freezing mountain altitudes — with enclosures rated IP54 or higher for dust and water ingress protection. Anti-corrosion coatings, stainless steel fittings, and UV-protected control panels ensure longevity even in aggressive atmospheres. In conclusion, the next generation of diesel fire pump systems marks a significant leap forward in fire protection technology. Combining mechanical reliability with smart electronics, these units offer unmatched efficiency, flexibility, and safety. Intelligent monitoring and remote control are no longer optional but fundamental requirements in modern firefighting systems. As urban landscapes become more complex and fire risks more varied, these systems provide the scalable, intelligent, and autonomous solutions needed to protect lives and assets under all conditions. Whether for new construction, system upgrades, or high-risk industries, investing in a smart diesel fire pump system is a proactive step toward comprehensive and future-ready fire protection.