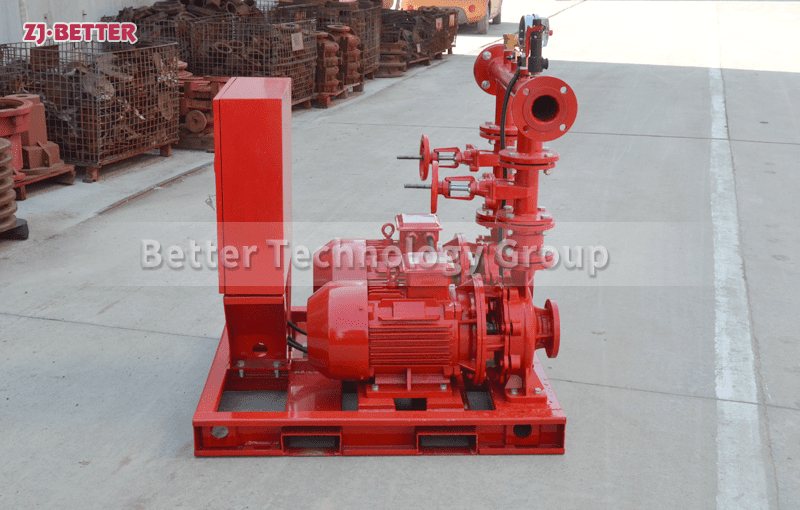

Fire Pump Set Manufacturer

Better Technology Group Co., Ltd. is a professional fire pump manufacturer with more than 20 years of industry experience and is deeply loved by domestic and foreign customers.

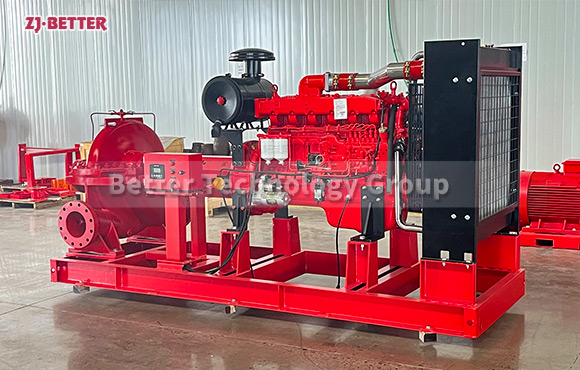

The diesel engine fire pump has a wide range of lift and flow, which can fully meet the fire water supply in various occasions such as warehouses, docks, airports, petrochemicals, power plants, liquefied gas stations, textiles and other industrial and mining enterprises.

Diesel engine fire pumps are relatively common in life, and their performance requirements are relatively high. In ordinary use, more attention should be paid to maintenance, so as to prolong the service life of the pump. Because diesel fire pumps are not omnipotent, there will be some problems in daily use, so when choosing equipment, we must pay attention to whether the quality of the equipment meets the national standards. As fire equipment, all kinds of equipment must be To ensure performance, avoid affecting use in disaster situations and delaying rescue.