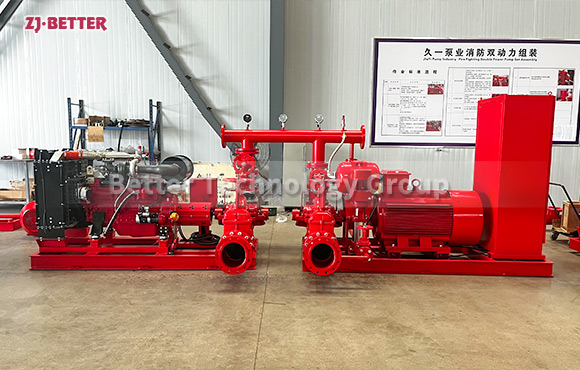

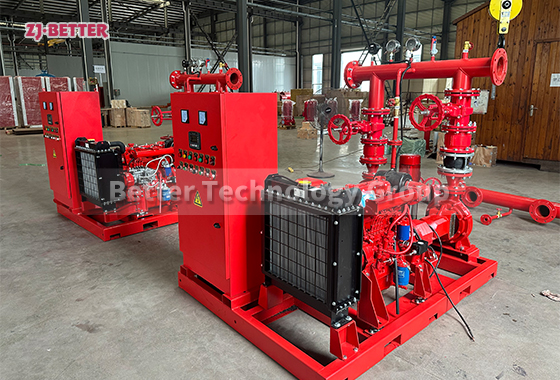

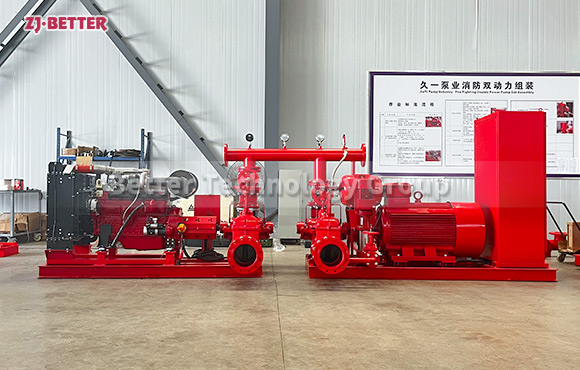

Diesel Fire Pump with Integrated Valve and Piping System for Precise and Stable Fire-Fighting Water Supply

Equipped with control valve groups and piping systems, the diesel fire pump achieves precise and stable water supply and rapid emergency start-up. It features high head, large flow rate, and strong environmental adaptability, making it suitable for various building and industrial fire protection systems.

Diesel fire pumps equipped with control valve assemblies and piping systems are indispensable core power equipment in modern fire protection engineering. They are widely used in key areas such as high-rise buildings, industrial plants, warehousing and logistics parks, petrochemical bases, and municipal fire stations. Through an independent power system and complete valve and piping components, they achieve more precise, stable, and continuous fire water supply capabilities, ensuring rapid startup and providing sufficient fire-fighting water pressure and volume in any emergency to meet the stringent performance requirements of international fire protection standards and industry specifications. The most significant advantage of this type of diesel fire pump is its complete independence from mains power. It maintains a strong and stable output even in the event of power failure, grid instability, harsh environments, or power outages caused by disasters. This is crucial for ensuring the water supply capacity of building fire protection systems under extreme conditions, thus possessing irreplaceable value in terms of fire protection reliability, emergency adaptability, and equipment stability. Its power unit uses a high-performance diesel engine as the drive source. Through a high-efficiency combustion system, reinforced cylinder structure, and optimized fuel injection strategy, the engine maintains strong torque output and low fuel consumption even in harsh environments, while reducing vibration and noise and improving overall operational stability. To meet the requirement of rapid response in emergency situations, diesel engines are typically equipped with automatic preheating devices, intelligent ignition systems, cold start assistance modules, and adaptive intake systems. This allows for rapid startup even in environments with low temperatures, high humidity, or significant altitude variations, minimizing the time between receiving an instruction and initiating stable water supply, effectively enhancing the overall rapid response capability of the fire protection system. Furthermore, the equipment utilizes a precision-machined pump body, typically a single-stage or multi-stage centrifugal structure, combined with corrosion-resistant impellers, thickened pump casings, and optimized flow channel design. This not only improves the pump’s hydraulic efficiency but also ensures stable pressure output during prolonged continuous operation, preventing issues such as head reduction, excessive temperature rise, or insufficient flow. The pump shaft and mechanical seal components are made of high-strength materials, and the lubrication and cooling design extends the pump’s service life and reduces maintenance costs. It is worth emphasizing that the superior performance of this type of diesel fire pump is primarily due to its specialized control valve assembly and comprehensive piping system. These key components not only achieve automatic regulation of fire water supply but also significantly improve the accuracy and stability of the water supply. A valve assembly typically includes check valves, gate valves, pressure relief valves, safety valves, test valves, filters, and air vents. These valves work together to control water flow direction, water pressure stability, and pipeline safety, making the entire fire-fighting water supply process more reliable. At the moment of fire start-up, the valve assembly automatically regulates pressure to prevent water hammer and ensure pipeline safety. During stable pump operation, the pressure valve automatically maintains a constant pressure output, ensuring stable operation of the sprinkler system, fire hydrant system, and water curtain system at their design pressure. When the fire pump stops operating, the check valve immediately closes to prevent backflow and pressure drop, thus achieving true continuity of water supply. The control valve assembly also plays a crucial role in system protection. For example, when abnormal pressure occurs in the pipeline, the pressure relief valve can quickly release pressure to prevent damage caused by excessive pressure; the filter keeps the pipeline clean when the water source contains many impurities, reducing pump wear; and the automatic air vent ensures no air accumulation in the system, preventing air resistance from affecting flow. The scientific layout of these valves and piping systems ensures that this type of diesel fire pump not only possesses powerful performance but also a high level of system safety. The supporting piping system utilizes corrosion-resistant carbon steel, stainless steel, or hot-dip galvanized steel pipes, and undergoes rigorous welding and pressure testing to ensure stable, leak-free operation under high pressure, high flow, water hammer, and complex operating conditions. The carefully designed piping layout facilitates smoother water flow, reducing flow resistance and energy consumption while improving power utilization. Furthermore, the rationally arranged inspection and maintenance ports facilitate later maintenance, pressure testing, and repairs, minimizing downtime and enhancing the overall sustainability of the fire protection system. This diesel fire pump set is also equipped with an advanced automatic control system, enabling automatic, manual, and remote start-up. It can interface with fire alarm centers, fire monitoring systems, PLCs, and building integration systems for intelligent management. When fire water pressure decreases, water flow signals appear in the pipeline, or a linkage command is issued by the fire control center, the pump set can automatically start and operate stably within the set pressure range. The system features delayed start-up, automatic switching, fault diagnosis, status display, data logging, and remote monitoring functions, making fire protection system management more efficient. The controller is equipped with high-precision sensors, including oil pressure sensors, water temperature sensors, speed sensors, and voltage detection modules. Real-time data acquisition ensures the diesel engine operates under normal conditions and provides audible and visual alarms or automatic shutdown protection when parameters are abnormal to prevent equipment damage. The control system also has a backup battery for power outages, ensuring automatic start-up even in complete power failure. The entire system is designed for compactness, safety, and ease of maintenance. The base is constructed from thickened steel, providing high load-bearing capacity and seismic resistance, adapting to the vibration environment of industrial sites and long-term operational requirements. The entire unit is mounted on a single base, simplifying transportation, hoisting, and on-site installation while occupying less space, making it suitable for fixed installation or mobile emergency devices. To reduce operating noise and vibration, the base is often equipped with shock-absorbing pads for smoother operation. This diesel fire pump is also suitable for complex operating conditions, such as high temperature, high humidity, dusty environments, and salt spray corrosion. Its overall reliability is enhanced through corrosion-resistant coatings and sealing designs. Compared to traditional electric fire pumps, this type of equipment has stronger environmental adaptability, making it particularly suitable for projects in open or remote areas, such as oil depots, docks, mines, and field tank farms. It boasts high durability, a low failure rate, and easy parts replacement, making it a reliable choice for long-term operation. The equipment exhibits outstanding performance, featuring high head, strong flow rate, stable pressure, rapid start-up, and the ability to operate continuously for extended periods. It has high hydraulic efficiency, and the head can be designed according to requirements, with flow rates covering applications ranging from small commercial buildings to large industrial facilities. It can operate continuously for several hours under rated conditions without power loss or pump overheating. Its advanced cooling, lubrication, and fuel supply systems work together to ensure the engine remains in optimal condition during long-term operation. In summary, diesel fire pumps equipped with control valve assemblies and piping systems are professional fire-fighting equipment that combines high reliability, high safety, high performance, and high adaptability. Their advantages include independent operation from a power source, rapid start-up, powerful output, precise and stable pressure control, a comprehensive valve protection system, reliable piping structure, intelligent automatic control, adaptability to harsh environments, and the ability to operate continuously for extended periods. They provide high-standard, high-reliability emergency fire-fighting power for various buildings and industrial facilities, and are core equipment for meeting modern fire safety standards, enhancing the safety level of fire protection systems, and reducing operational risks. Their overall design, from power source, pump body, valve assembly, piping to control system, has been meticulously planned to ensure immediate start-up and continuous stable operation in critical moments, making them an irreplaceable and vital piece of equipment for protecting life and property.