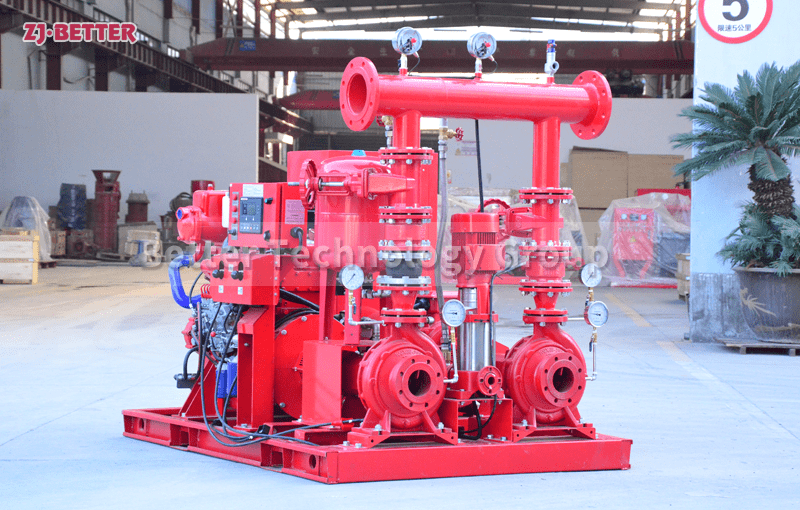

Direct-Coupled Horizontal Fire Pump with Compact Structure and Stable Performance

The direct-drive horizontal fire pump features a compact structure, stable operation, high efficiency, high reliability, and low maintenance costs. It is suitable for fixed fire water supply systems in buildings, industries, and municipalities, ensuring a continuous and stable output of fire water in emergency situations.

This direct-drive horizontal fire pump is a high-reliability fire pump specifically designed for stationary fire water supply systems. Its overall structure utilizes a direct connection between the motor and pump body, eliminating traditional couplings and complex intermediate transmission components. This results in a more compact and rational overall layout, significantly improving operational stability and service life while ensuring high hydraulic performance. With stable output, high efficiency, and low failure rate as its core design goals, this product is widely applicable to building fire pump rooms, industrial plant fire protection systems, municipal fire pipelines, warehousing and logistics parks, energy facilities, and other locations with extremely high requirements for continuous fire water supply. Structurally, this horizontal fire pump adopts a standardized horizontal end-suction structure, resulting in a low center of gravity and stable operation, effectively reducing vibration and noise. It is particularly suitable for long-term standby and sudden start-stop conditions. The precise coaxial direct connection between the motor and pump shaft achieves efficient power transmission, avoiding bearing wear and mechanical failures caused by coupling eccentricity or looseness, and significantly reducing maintenance frequency. In terms of efficiency and operational risks, the fire pump is optimized based on a mature centrifugal pump hydraulic model. The impeller is precision-cast from high-strength wear-resistant materials and dynamically balanced to ensure stable flow and head at rated speed. Even under high load or continuous operation, it maintains a good efficiency curve, meeting the stringent requirements of fire protection systems for instantaneous high-flow and high-pressure water supply in emergency situations. The pump casing adopts a thick-walled structure design, with high overall strength and pressure resistance, adapting to the long-term operation of high-pressure fire pipelines. The internal flow channel is smoothed to effectively reduce hydraulic losses and turbulence, improving overall energy efficiency and reducing energy consumption. The sealing system is a major performance advantage of this product. The shaft seal adopts a high-reliability mechanical seal structure, combined with high-temperature and corrosion-resistant materials, maintaining good sealing performance under frequent start-stop and long standby conditions, avoiding leakage risks and ensuring the fire pump can be quickly put into operation in critical moments. (Bearing section) The use of heavy-duty bearings and a well-designed lubrication system ensures stable operation even under prolonged running or high-speed conditions, effectively extending service life and reducing operating noise. The horizontal fire pump is equipped with a dedicated fire motor, boasting excellent starting performance and overload capacity. It can quickly start and operate stably under voltage fluctuations or high starting loads, ensuring rapid response and timely rescue. The direct-drive structure not only improves transmission efficiency but also significantly simplifies installation. The equipment is pre-assembled and tested at the factory; on-site installation only requires foundation fixing and pipe connection, greatly reducing installation difficulty and construction time. This is particularly suitable for projects with tight schedules and limited site conditions. In terms of maintenance, the fire pump’s simple structure and high component versatility make daily inspection and maintenance easier, reducing the risk of system downtime due to complex maintenance and contributing to lower overall system performance. In terms of overall operation and maintenance costs, and from a safety and reliability perspective, this product fully considers the special usage requirements of fire protection systems during the design phase, emphasizing the stability and predictability of the equipment under extreme operating conditions. Even when in standby mode for extended periods, it can quickly reach rated operating conditions upon receiving a start-up command, ensuring continuous and stable fire water supply capacity. Furthermore, this horizontal fire pump undergoes strict control in material selection and manufacturing processes. Key pressure-bearing components are made of high-strength materials and have undergone rigorous testing and performance evaluation to ensure reliable performance under various environmental conditions. Overall, this direct-drive horizontal fire pump, with its compact structure, high-efficiency transmission, stable operation, and convenient maintenance, provides a professional fire water supply solution that balances performance and reliability for various fixed fire protection systems. It can continuously and stably output fire water at critical moments, providing a solid guarantee for building and industrial safety, making it a reliable core equipment choice in modern fire protection engineering.