Main features of diesel engine automation control cabinet

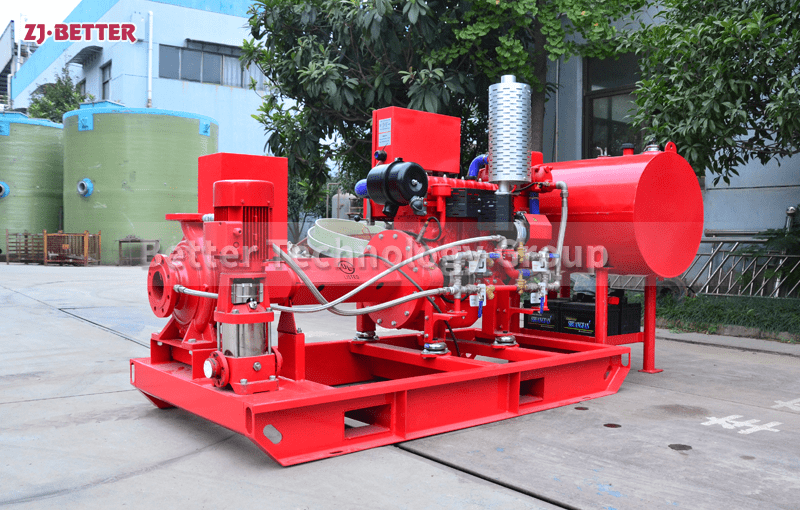

Our company’s fire pump equipment is widely used in state agencies, various residences, pressurized pump stations, hotels, schools, hospitals, etc. due to its outstanding features such as environmental protection, energy saving, and safety.

Main features of diesel engine automation control cabinet

1. Automatic start: After the diesel water pump unit receives a fire alarm/pipe network pressure/power failure/or other start signals, it can automatically start within 15 seconds and put into full-load operation;

2. Automatic charging: the battery can be automatically charged by the mains or diesel charging motor to ensure the smooth start of the unit;

3. Automatic alarm: automatic alarm protection for diesel engine low oil pressure, high water temperature and other faults, alarm and stop when overspeed;

4. Automatic preheating: make the diesel engine in a hot engine standby state to ensure emergency work;

5. Direct connection type: The diesel water pump unit below 360kw adopts the innovative direct connection technology between the diesel engine and the water pump through an elastic coupling, which reduces the point of failure, greatly shortens the starting time of the unit, and increases the reliability and emergency performance of the unit;

6. Users can also request to set other alarm outputs (non-standard supply);

7. With remote measurement, remote signaling, remote control functions (non-standard supply);