Low Maintenance, High Output: Structural Advantages of Diesel Fire Pumps

Optimized structure improves performance, intelligent integration simplifies maintenance – learn how high-efficiency diesel fire pumps operate stably in extreme environments and become the ideal choice for industrial and municipal fire protection systems.

In today’s industrial and municipal fire protection systems that focus on efficiency and reliability, diesel fire pumps are becoming an indispensable core equipment. Its independent operation from the power supply gives it an unparalleled advantage in emergency response to fires in power outages or remote areas. Compared with traditional electric pumps, diesel drive systems can continuously provide stable and efficient hydraulic output in extreme environments, ensuring rapid response and lasting support at critical moments.

In order to achieve the goal of “low maintenance and high performance”, advanced diesel fire pumps have made many optimizations in structural design. From the selection of pump body materials to the matching of drive components, from the integration of control systems to the modular layout of the overall system, every detail has been rigorously verified and field tested. This structural optimization not only extends the service life of the equipment, but also greatly reduces the operation and maintenance burden during use, and improves the availability and economy of the overall system.

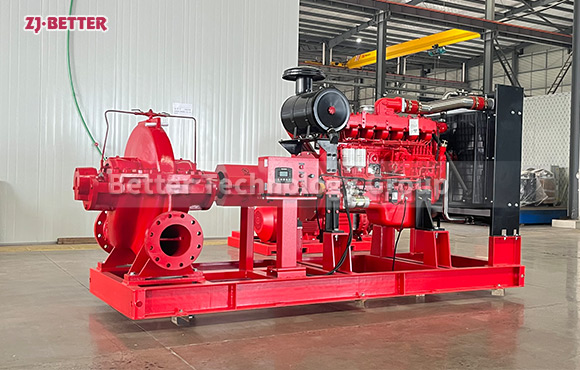

The pump body of a diesel fire pump is usually made of high-strength cast iron or stainless steel, which can effectively resist water hammer impact, chemical corrosion and fatigue loss caused by long-term vibration. At the same time, the optimized impeller curve and hydraulic channel design are used inside, so that the pump can maintain a high efficiency even when running at low speed, thereby reducing energy consumption and mechanical wear. This design concept not only reduces the replacement frequency of wearing parts, but also effectively extends the maintenance cycle of the equipment.

The drive part is usually equipped with a high-efficiency industrial diesel engine, and is equipped with a low-noise exhaust system and a high-capacity cooling module to achieve long-term high-load operation without overheating. The system also adds automatic configurations such as electric start, battery backup, and fuel double filter, which further reduces the need for manual intervention. In daily use, users only need to regularly check the fuel reserves, coolant level and lubricating oil status to achieve stable operation, which greatly improves the simplicity and safety of operation and maintenance.

In terms of intelligence, modern diesel fire pumps are generally equipped with PLC control systems or remote monitoring modules, which can realize real-time collection, diagnosis and remote alarm of the operating status of the pump group. These digital functions not only facilitate users to understand the current health status of the system, but also provide early warnings at the beginning of the failure, thereby effectively avoiding system paralysis caused by sudden equipment failure. In some high-demand occasions, it can also be connected to the host computer system according to customer needs to achieve a higher level of network control and unified management.

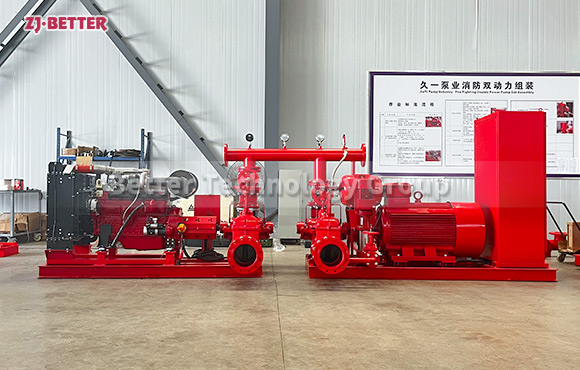

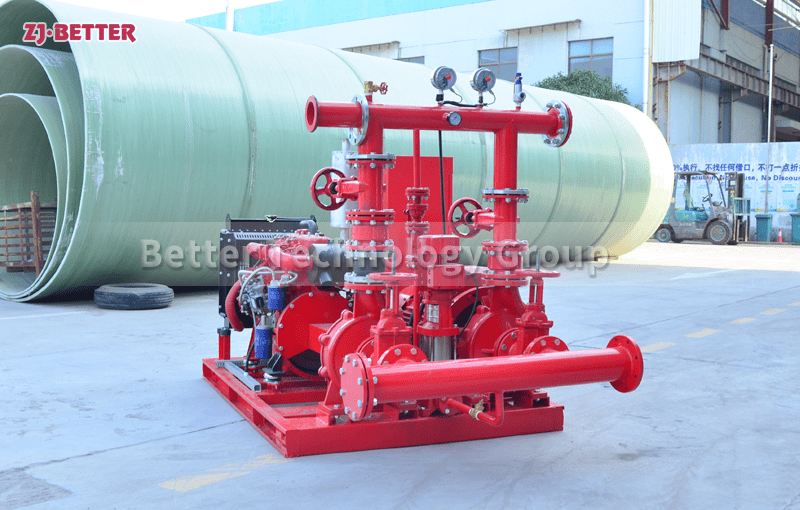

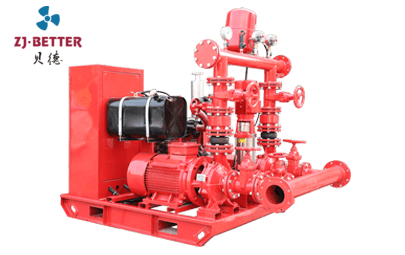

In addition, modular design is also one of the important directions for the structural optimization of diesel fire pumps. By pre-installing the diesel engine, water pump, control system, and pipeline components on the same base to form a highly integrated integrated unit, it not only simplifies the on-site installation process, but also greatly shortens the construction period. This modular solution is particularly important for renovation projects or occasions with limited on-site space. It not only saves installation area, but also makes subsequent maintenance and replacement easier.

It is worth mentioning that the optimized diesel fire pump shows extremely high reliability in operation. Even in low temperature, high temperature, high altitude or humid corrosive environment, it can stably start and maintain the set flow and pressure output. This wide adaptability makes it the preferred equipment for key places such as petrochemicals, electric power, ports and terminals, warehousing and logistics, and truly embodies the core value of “never falling off the chain at critical moments”.

From the perspective of use cost, although the initial investment of the diesel fire pump is relatively high, due to its high efficiency, low loss and long life brought by its structural optimization, it can significantly reduce maintenance costs and downtime risks in long-term operation, thereby improving the return on investment of the entire project. This is an extremely attractive solution for customers who pursue long-term stability and high reliability.

In summary, low-maintenance, high-performance diesel fire pumps, with their structural optimization and technical integration advantages, have played an important role in modern fire safety systems. Whether in the field of building fire protection, industrial protection or emergency rescue, they have become an important guarantee for dealing with fire risks with their excellent reliability and efficient operation capabilities, providing strong safety support for various scenarios.