A New Perspective on Emergency Power: Stability Meets Flexibility in Diesel Fire Pumps

The mid-pressure diesel fire pump system offers independent power, precise control, and high-efficiency output—ideal for high-risk environments. Explore its intelligent control, design features, and application benefits.

In the context of the ongoing upgrading of modern building fire safety systems, fire pump equipment is undergoing a profound transformation from traditional operation to intelligent control, and from low efficiency to high performance. Especially in high-risk, high-demand locations such as industrial plants, large commercial complexes, airports, oil depots, and ports, medium-pressure diesel fire pump systems have become critical equipment for addressing complex emergency fire situations due to their unique independent power supply capability, exceptional water pressure output, stable operational performance, and highly automated control capabilities. This article will delve into the structural composition, performance advantages, technical highlights, and application value of medium-pressure diesel fire pump systems, providing an in-depth analysis of the exceptional capabilities they demonstrate in terms of intelligent innovation.

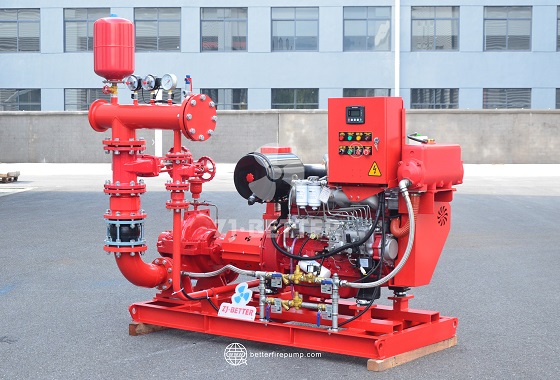

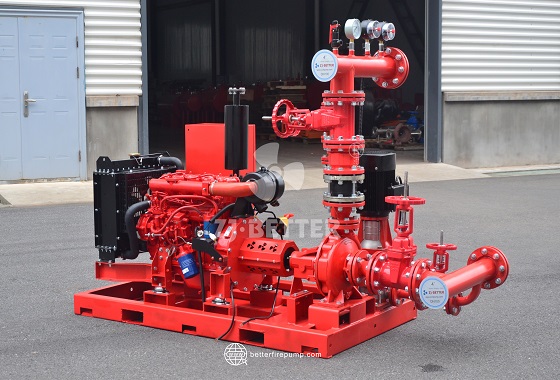

Medium-pressure diesel fire pump systems typically consist of core components such as diesel engines, fire pumps, hydraulic control systems, automatic control cabinets, buffer air tanks, inlet and outlet water pipes, and pressure sensors. The entire system is integrated onto a unified base, featuring compact structure, independent operation, and rapid response. The core of the system lies in the diesel engine’s drive mechanism, which does not rely on municipal grid power supply, making it suitable for special scenarios where power supply is unreliable. Additionally, through precisely matched hydraulic curves and medium-pressure output characteristics, this type of pump system can achieve efficient integration between low-pressure and high-pressure systems, delivering optimal performance in multi-story buildings and large-scale sprinkler networks.

From the perspective of intelligent control, the system is equipped with a high-performance control module that integrates multi-functional PLC programming logic, enabling intelligent management of the entire process, including start-up logic, water pressure feedback, operational alarms, and standby conversion. The control cabinet panel features an LCD screen and multi-functional buttons, allowing users to intuitively read real-time parameters such as inlet/outlet pressure, pump speed, operating temperature, and fuel/battery levels through the human-machine interface, thereby achieving comprehensive monitoring of the equipment’s status. When water pressure drops below the set threshold, the system can automatically start the diesel pump; in the event of an electric pump failure, it can also automatically switch to the diesel pump to continue operation, forming a redundant protection mechanism and significantly enhancing the reliability of the fire protection system.

Additionally, the system is equipped with pressure sensors and electric contact pressure gauges, combined with solenoid valves and electric control relay modules. In cases of abnormal pressure or overheating, the system automatically issues an alarm signal and, based on pre-set programs, automatically shuts down or switches modes to prevent equipment overload damage. In terms of safety protection, the system is equipped with a one-button emergency stop button, control cabinet overload protection, fuel tank flame arresters, exhaust silencer systems, and oil leakage prevention measures, ensuring stable operation and safety under extreme working conditions.

In terms of energy efficiency management, the medium-pressure diesel fire pump system is centered on medium-speed control, capable of delivering a stable water pressure of 7–12 bar to meet the requirements of fire protection systems in mid-to-high-rise buildings, while maintaining a low-power standby mode during periods of idle operation through energy-saving design. The diesel engine is equipped with high-efficiency, energy-saving brand models, featuring high combustion efficiency, rapid startup, and the ability to operate in high-altitude and low-temperature regions. It also supports the use of commercially available diesel fuel mixed with National VI standard environmentally friendly fuel, meeting various engineering environmental protection acceptance requirements.

In terms of manufacturing processes, the entire unit employs a powder-coated corrosion-resistant finish. Critical components such as the pump body, impeller, and shaft seal are constructed from wear-resistant alloys or stainless steel, ensuring long-term durability in complex water conditions including corrosive liquids, sand-laden water, and desalinated seawater. The piping system is lined with an epoxy resin coating to enhance pressure resistance and corrosion protection. The base frame is constructed from thickened steel plates welded in a single piece, providing robust seismic resistance and suitability for use in earthquake-prone or high-load areas.

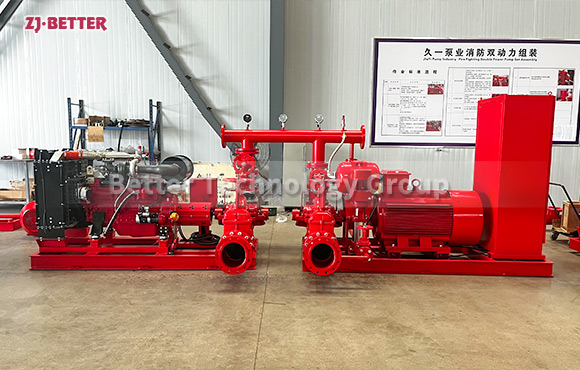

In terms of project integration, the medium-pressure diesel fire pump system supports multi-module integration, including a three-in-one configuration of a diesel main pump + electric standby pump + pressure-stabilizing pump, enabling coordinated control for different flow and pressure requirements. It can also be integrated with building fire protection systems, remote BAS/fire monitoring platforms, enabling cloud-based early warning and maintenance management. Additionally, optional features such as GPS positioning, fuel level remote transmission, and data report export are available, helping users achieve full-process information management from procurement, installation, operation to maintenance.

Due to its highly integrated, independent operation, and safe intelligent features, the medium-pressure diesel fire pump system is widely applied in industries such as power, chemicals, petroleum, metallurgy, aviation, and shipping, particularly suitable for critical infrastructure projects with extremely high power supply requirements or risks of power outages. Compared to traditional electric fire pumps, its advantages are not only reflected in emergency response speed but also in the system’s strong independence, ease of maintenance, and low lifecycle costs, making it a reliable mid-to-high-end emergency fire pump solution in the industry.

With the continuous advancement of AI control technology and IoT communication technology, future medium-pressure diesel fire pump systems will achieve higher-level innovations and upgrades in areas such as intelligent predictive maintenance, remote multi-point control, and self-regulating operational efficiency. As a professional manufacturer of fire pump systems, ZJ-BETTER remains committed to the technological research and development and performance optimization of medium-pressure diesel fire pumps, dedicated to providing global customers with safer, more efficient, and smarter fire water supply solutions.

.jpg)