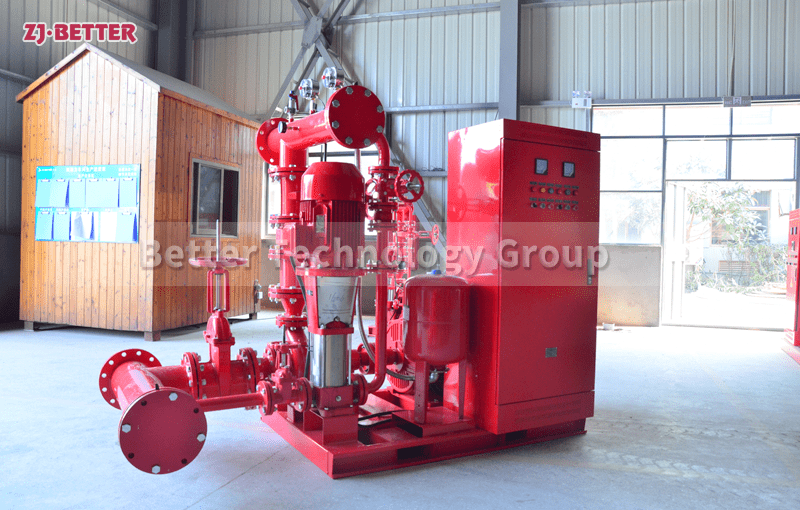

A fire pump set is a reliable piece of equipment

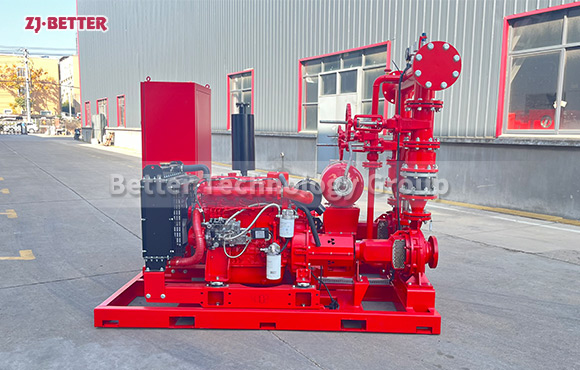

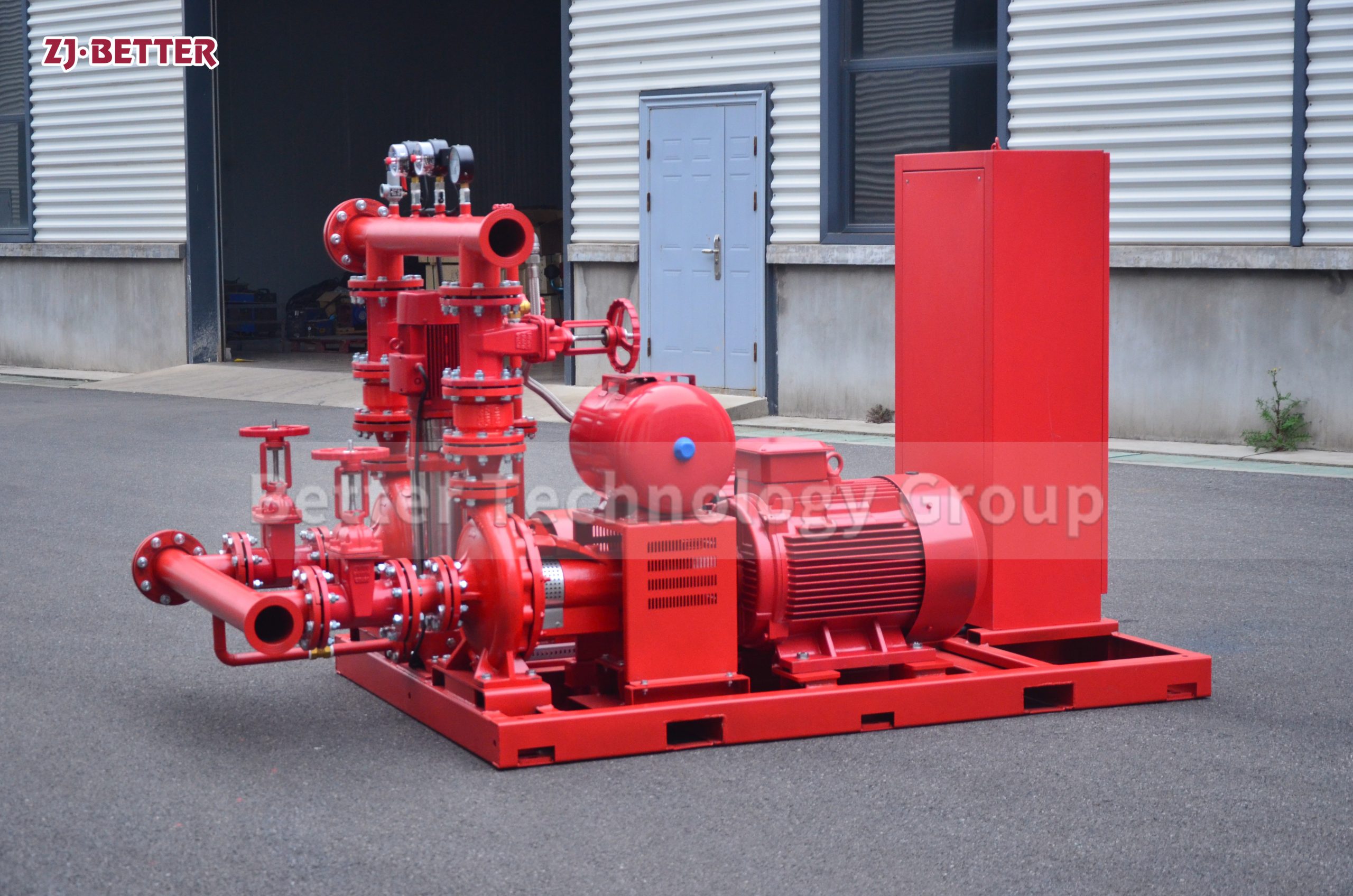

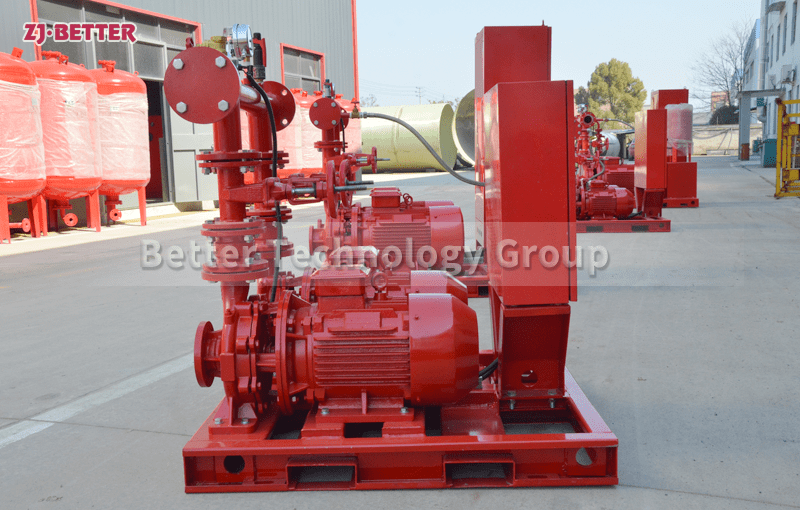

The dual power fire pump is composed of a fire water pump, a double shaft extension motor and a diesel engine. One end of the output shaft of the double shaft extension motor is connected with the input shaft of the fire pump, and the other end of the output shaft of the double shaft extension motor is One end of a clutch is connected, and the other end of the clutch is connected with the output shaft of the diesel engine. The fire water pump, the double-shaft extension motor, the clutch and the diesel engine are all fixed on the base. The double shaft extension motor, the clutch and the diesel engine are respectively electrically connected with a control circuit through an action drive circuit. With dual-power fire pumps, there is no need to configure a second fire pump, which reduces floor space and saves manufacturing costs.

1. Due to the dual power, when a fire occurs, it is a more reliable way to ensure water safety;

2. The electric pump set is put into operation when the mains power is normal. When the power supply fails and the electric fire pump cannot be put into use normally, the diesel engine fire pump set can be put into operation automatically to ensure the normal progress of fire fighting. The diesel engine fire pump set is equipped with various automatic functions. , to meet the requirements of the standard, to ensure the long-term normal standby state of the equipment, and to put it into fire fighting work at any time.

3. The fire-fighting dual-power water supply equipment is suitable for various emergency backup pump places.

The dual-power fire pump is mainly used for various fire hydrants and spray fire main pumps. It is also suitable for various fire booster and pressure stabilizing pumps. It is also suitable for various villas, residential areas and other fire systems, industrial It is also suitable for various oil depots, oil loading and unloading docks, logistics parks and other places with high fire protection level requirements.