Lightweight and Efficient Protection: Performance Advantages of Air-Cooled Diesel Fire Pumps

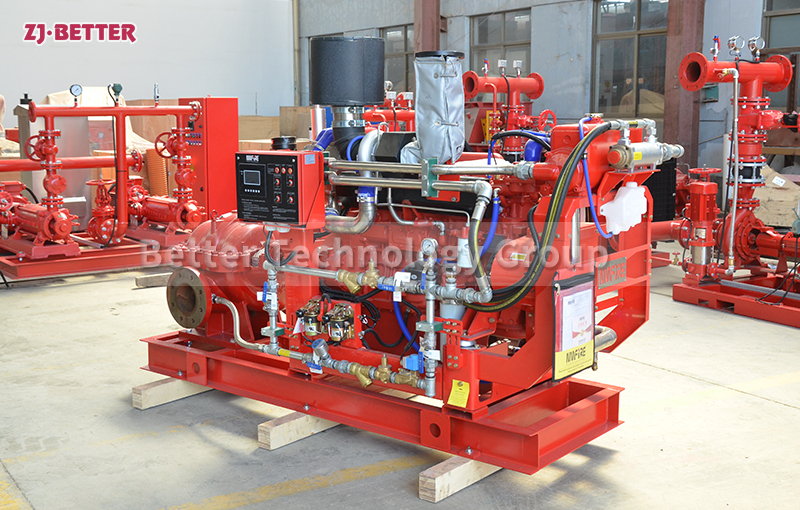

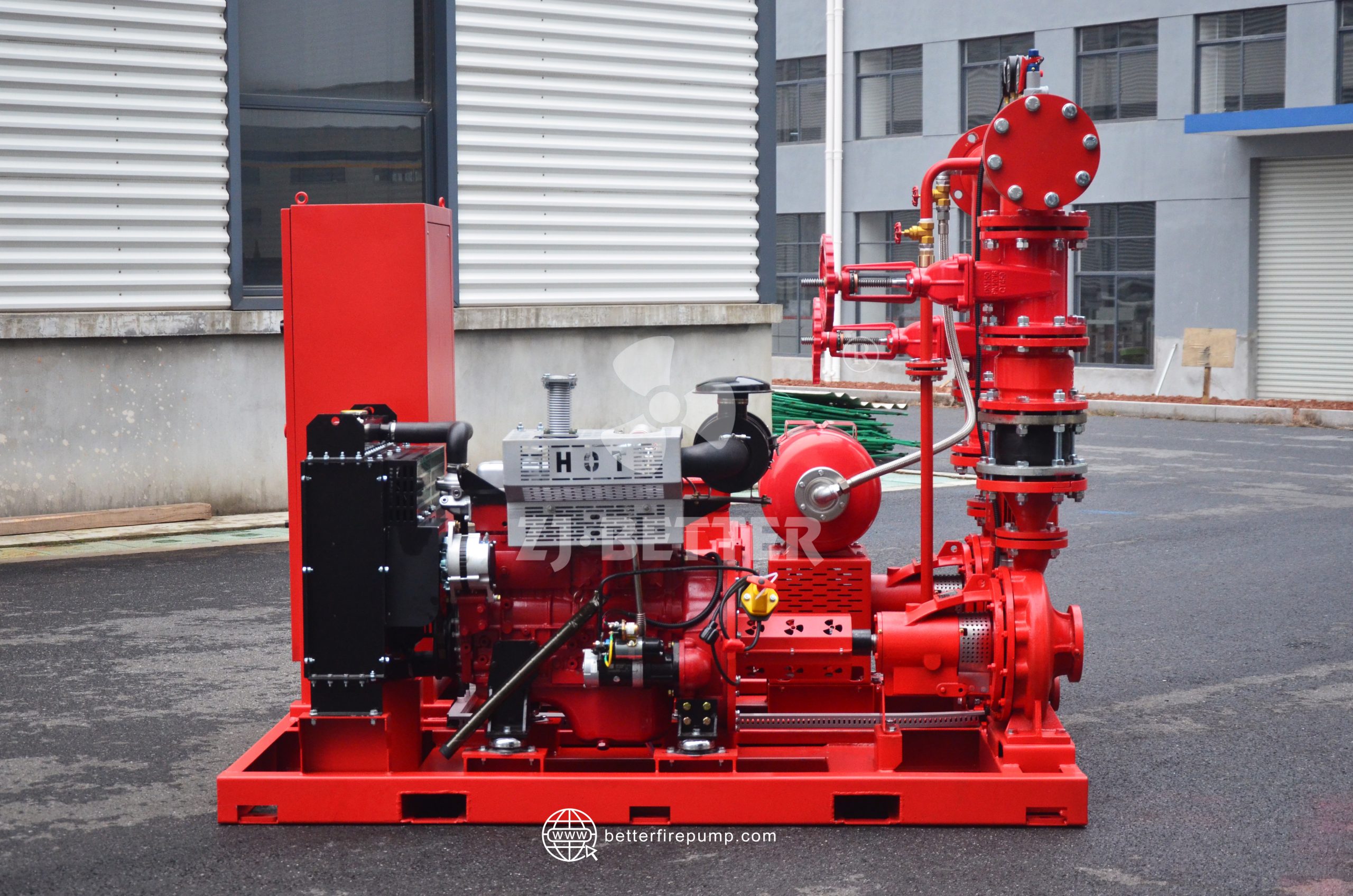

Air-cooled diesel fire pumps are highly efficient, stand-alone firefighting equipment, offering powerful power, no need for a water cooling system, energy conservation, environmental protection, and easy maintenance. They provide a stable water supply even in power outages or extreme environments, ensuring rapid and reliable fire emergency response. They are widely used in firefighting systems in factories, warehouses, docks, and remote areas.

As a representative independent power water supply system in modern firefighting equipment, the air-cooled diesel engine fire pump, with its lightweight, efficient, compact structure, stable performance, and easy maintenance, is an ideal choice for responding to various fire emergencies and providing water supply in areas without electricity. Combining the powerful power of a diesel engine with the adaptability of air cooling technology, this fire pump can operate independently without an external power source, providing a stable fire water supply for buildings, factories, warehouses, mining areas, docks, and remote mountainous areas. The core advantage of the air-cooled diesel engine fire pump lies first in its power system. It uses an efficient and energy-efficient diesel engine as its driving force, offering strong output power and long-lasting endurance. Compared to traditional electric fire pumps, its greatest advantage is that it does not rely on an external power system. It can quickly start up and operate even in the event of a power outage, blackout, or interruption, ensuring uninterrupted fire water supply. This independent operation makes it irreplaceable in emergency response during natural disasters, outdoor operations, remote areas, and temporary construction sites. The air cooling system design is another highlight of this type of fire pump. Compared to traditional water-cooled diesel engines, air-cooling eliminates the need for an additional cooling water source, preventing equipment downtime due to water shortages or freezing. The forced air cooling system allows the diesel engine to maintain stable operation even in hot or arid regions, significantly improving the equipment’s environmental adaptability. Its compact cooling structure occupies little space, making it suitable for mobile or portable use. It is particularly well-suited for emergency firefighting operations in remote areas, mountainous areas, and temporary construction sites. The pump body of an air-cooled diesel fire pump is constructed of high-strength, corrosion-resistant materials, ensuring long-term operation unaffected by water quality and climate. The optimized internal flow path improves water flow efficiency and reduces energy loss, enabling the unit to deliver high head and high flow at low power, meeting the requirements of industrial and municipal firefighting systems. The dynamically balanced impeller ensures smooth operation, low vibration, and low noise, effectively extending the service life of bearings and seals. In terms of control systems, these devices are typically equipped with an intelligent control panel featuring automatic start, shutdown, alarm, and protection functions. Upon detecting a pressure drop or a fire signal, the system automatically starts the diesel engine and rapidly supplies water, ensuring the shortest possible emergency response time. It also features multiple safety mechanisms, including low oil pressure protection, overtemperature alarm, and overload shutdown, to prevent damage caused by improper operation or equipment malfunctions. This highly automated control system greatly simplifies the user experience, ensuring safe operation even when unattended. The air-cooled diesel fire pump also boasts exceptional fuel efficiency. Its high-pressure fuel injection system and optimized combustion chamber design ensure efficient power output while effectively reducing fuel consumption, contributing to energy conservation and environmental protection. Compared to similar products, it offers lower fuel consumption and reduced carbon emissions, further aligning with current trends in green and low-carbon development. Even during long periods of continuous operation, the unit maintains excellent power output and cooling performance, without performance being affected by excessive temperature rise. Portability is a key feature of the air-cooled diesel fire pump. Its lightweight and compact design allows for easy installation on a small base or cart, enabling rapid transport and deployment. For temporary emergency response, field construction, and agricultural fire prevention, users can quickly move the unit to a water source for operations, significantly improving firefighting efficiency. Furthermore, its installation requirements are simple, requiring no complex infrastructure; it simply requires secure mounting before it can be used. This fire pump’s design is engineered for user convenience. Its air-cooling structure eliminates the tedious coolant changes and scale removal required in traditional water-cooled systems, reducing maintenance cycles. The diesel engine utilizes a modular design, ensuring component commonality and facilitating easy repair and replacement. The pump body utilizes mechanical or packing seals to prevent leaks and enhance system stability. For long-term users, this low maintenance and high reliability significantly reduces the total cost of ownership. In practice, air-cooled diesel fire pumps are widely used in factory fire protection systems, oil depots, storage bases, docks, chemical plants, highway service areas, construction sites, and rural water supply. They provide continuous and reliable firefighting water supply, particularly in areas without or with unstable power supply. They also excel in agricultural and forestry fire prevention, as well as emergency drainage. Their robust suction and high head ensure efficient water supply even from deep water sources or high-drop water intakes. In terms of technical performance, air-cooled diesel fire pumps feature high starting efficiency, fast response, high flow output, and long-term stable operation. Their rated speed can be flexibly adjusted to meet varying flow and head requirements. By optimizing the combustion system and pump hydraulic structure, overall efficiency reaches internationally advanced levels. Furthermore, the equipment can operate normally in low and high temperatures, high humidity, and dusty environments, fully demonstrating its excellent weather resistance and reliability. Safety is also a key design priority for air-cooled diesel fire pumps. Equipped with a fuel filtration system and exhaust fire prevention devices, these devices effectively prevent safety hazards caused by fuel impurities and high-temperature exhaust. Their electrical control unit is waterproof, dustproof, and shockproof, ensuring long-term operation in harsh environments. Furthermore, to facilitate operator monitoring of operating status, the control panel features an oil pressure gauge, water temperature gauge, tachometer, and operating indicator lights, displaying key parameters in real time, allowing users to instantly monitor equipment performance. The design philosophy of air-cooled diesel fire pumps embodies the evolving trends in modern firefighting equipment: high efficiency, low energy consumption, ease of operation, and adaptability. Whether used in fixed firefighting systems in urban buildings or mobile firefighting in the wild, this equipment delivers superior performance to meet water supply requirements in diverse scenarios. It’s not only an ideal solution for responding to power outages and disaster emergencies, but also a crucial piece of equipment for ensuring fire safety and improving emergency response efficiency. In the future of firefighting, air-cooled diesel fire pumps will continue to play a unique role, providing solid technical support for global fire safety with their stable and reliable performance, excellent energy efficiency, and excellent environmental adaptability. Their portability and efficiency not only simplify the equipment structure but also represent the ability to rapidly supply water and protect life and property in critical moments, embodying the core principles of modern firefighting equipment: safety, reliability, efficiency, and environmental protection.