Advantages of diesel fire pump and its application in engineering

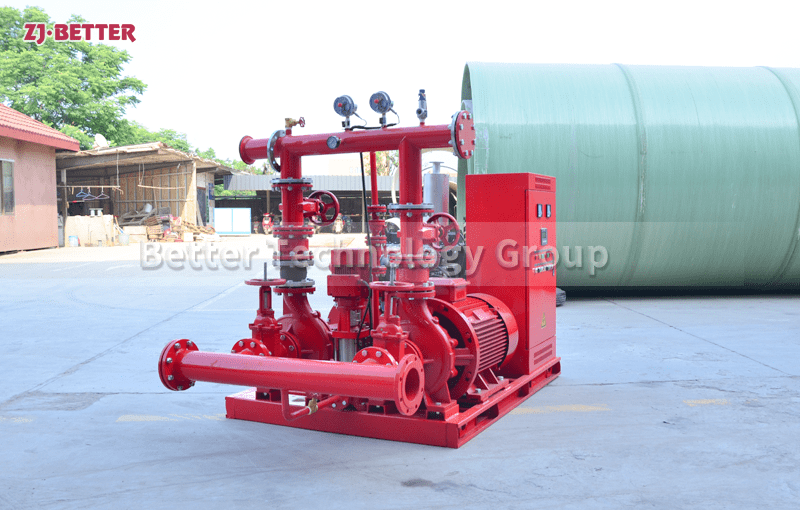

Diesel engine fire pumps are getting more and more attention, and the scope of use is becoming wider and wider. From the original pure water delivery to the current delivery of various domestic sewage, industrial wastewater, construction site drainage, liquid feed, etc. It plays a very important role in municipal engineering, industry, hospital, construction, hotel, water conservancy construction and other industries.

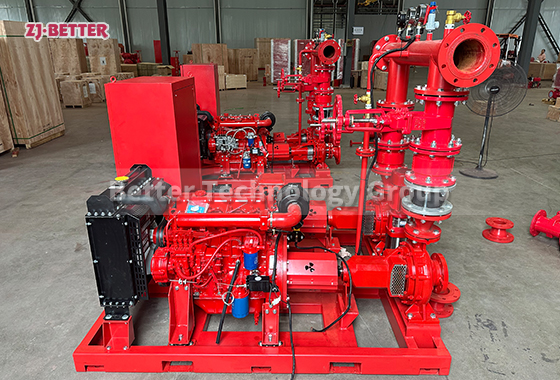

Diesel engine fire pump, as a fixed fire extinguishing equipment, has been widely used in fire diversion, especially in emergencies such as no power supply or abnormal power supply, other diesel engines can also be equipped as power engines according to user needs.

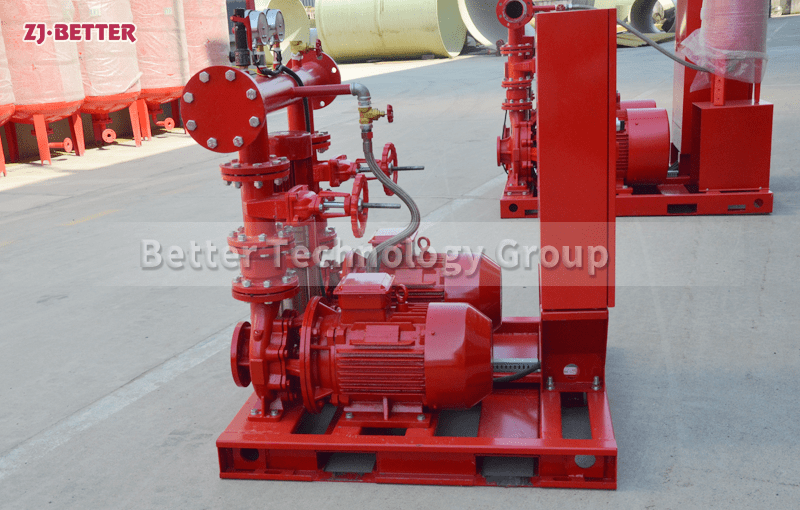

Diesel engine fire pump is mainly composed of diesel engine, fire pump, coupling, fuel tank, radiator, battery pack, intelligent automatic control panel, etc. The company’s products are designed and optimized by computers. Rich production experience and perfect testing methods ensure the stability and reliability of product quality.

.jpg)