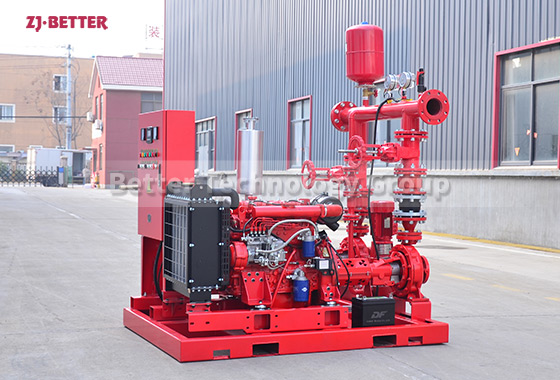

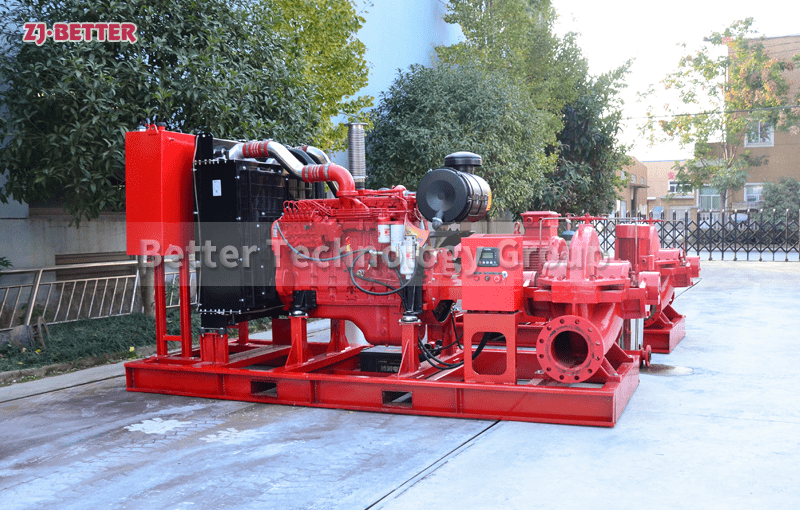

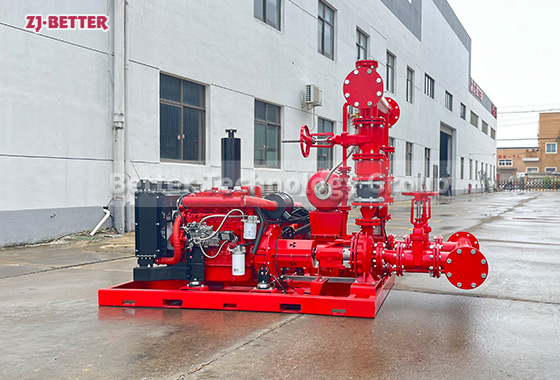

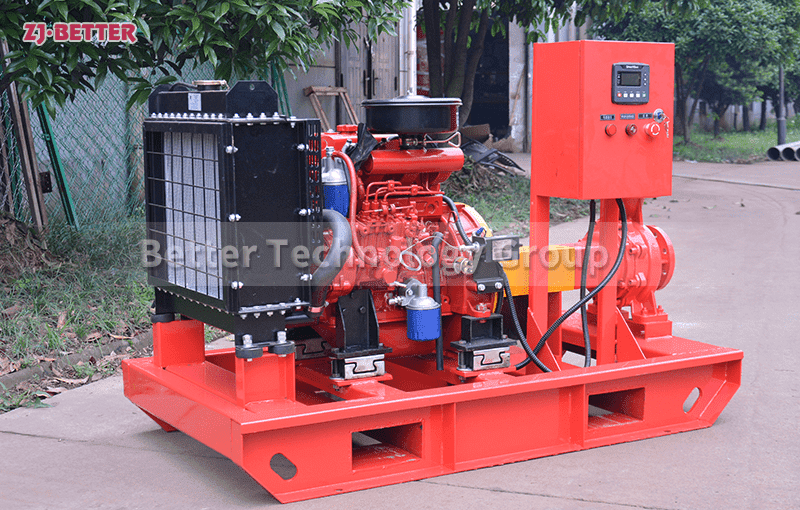

Lightweight Diesel Fire Pump Unit: Quick Deployment and Easy Maintenance

The lightweight diesel fire pump unit has the advantages of rapid deployment, independent power, low fuel consumption and high head. It is suitable for fire emergency, industrial water supply, agricultural irrigation and flood control and drainage. It ensures safe and efficient water supply in multiple scenarios, easy maintenance and reliable operation.

Lightweight Diesel Fire Pump Units: Rapid Deployment and Easy Maintenance. As a key component of fire water supply equipment, lightweight diesel fire pump units offer irreplaceable advantages in modern firefighting and emergency water supply thanks to their compact structure, portable design, independent power system, and stable performance. Compared to traditional large, fixed fire pump systems, these lightweight diesel units not only enable rapid deployment in complex and changing environments, but also meet market demands for both high efficiency and low costs through ease of transport, operational reliability, energy efficiency, and simplified maintenance. A key feature of these units is their lightweight design. By optimizing the structure of the pump body and power unit, the overall size and weight are reduced, making the entire unit easier to move and install while maintaining high water flow and high head. The unit’s portability makes it widely applicable in temporary firefighting operations, construction sites, factory workshops, warehouses and logistics parks, oil fields and mines, and remote areas without fixed water pumping stations. In emergencies, such as fires or municipal water supply outages, these lightweight diesel fire pump units can be quickly transported to the scene and immediately put into operation, significantly improving emergency response speed and firefighting efficiency. In terms of performance, lightweight diesel fire pump units utilize an energy-efficient diesel engine as their power source. This independent power mode ensures the unit can operate even without an external power supply, overcoming the limitations of electric fire pumps that rely on the power grid. The diesel engine offers strong starting performance and long-lasting performance, enabling stable operation even in harsh environments such as high temperature, dust, and humidity. Units are typically equipped with a large-capacity fuel tank, enabling continuous operation for hours or even longer, ensuring uninterrupted operation during firefighting or large-scale water supply operations. The pump body is constructed of wear-resistant alloy materials and high-strength bearings, and undergoes precision machining and dynamic balancing testing. It delivers both high head and high flow, meeting the diverse demands of high-rise buildings, expansive factory areas, and long-distance water delivery. Furthermore, the unit’s design prioritizes energy efficiency, with the diesel engine and pump body optimally matched to deliver strong power output while maintaining fuel economy, reducing operating costs. In terms of maintenance, lightweight diesel fire pump units are designed with simplicity in mind. The unit features a clear structure and a rational layout of functional modules, making replacement and inspection of common wearing parts easy, and routine maintenance can be completed without complex tools. The diesel engine is equipped with an automatic oil supply and lubrication system, reducing the need for manual operation and extending the engine’s service life. Some units are also equipped with an intelligent control panel that displays real-time parameters such as speed, water pressure, oil level, and operating time, allowing users to intuitively monitor equipment operating status and promptly address any anomalies. Furthermore, the intelligent design supports automatic alarms and emergency shutdown functions, effectively ensuring the safety of both equipment and operators. The lightweight design not only facilitates transportation and handling but also allows for flexible installation in confined spaces. Users can quickly deploy a water supply system tailored to site conditions without the need for time-consuming and complex installation. Lightweight diesel fire pump units have a wide range of applications. In urban firefighting, they are often used as emergency backup equipment in densely populated public places such as large shopping malls, stadiums, hospitals, and schools. In the event of a sudden fire, they can be activated immediately to ensure a continuous firefighting water supply. In the industrial sector, this type of unit is frequently used in high-risk enterprises such as petrochemical plants, metallurgical plants, and power plants, ensuring a stable, high-pressure water supply for sprinkler systems, fire hydrant systems, and water monitor systems in the event of a fire. At construction sites and mining areas, lightweight diesel fire pump units not only extinguish fires but also serve as temporary water supply equipment to meet construction and domestic water needs. These units are also widely used in agricultural irrigation and flood control and drainage. Their high-flow pumping capacity makes them excellent for irrigating large farmland and emergency drainage. Thanks to the diesel engine’s powerful performance and durability, these units can also meet the unique needs of remote areas and those without power grid coverage, becoming a key component in ensuring water supply security. The lightweight diesel fire pump unit is designed with safety and user-friendly features in mind. The unit’s casing and control system are waterproof and dustproof, making it suitable for use in changing outdoor climates. It offers a variety of starting methods, including electric starting and a manual emergency start function to ensure successful ignition in the event of an electrical system failure. The optimized exhaust system reduces noise and exhaust emissions during operation, meeting environmental requirements and improving the operating environment. To enhance overall reliability, the manufacturing process strictly adheres to international fire pump standards and testing specifications. Every unit undergoes high-lift, continuous operation, and safety protection function tests before leaving the factory, ensuring stable operation under extreme conditions. Furthermore, lightweight diesel fire pump units are undergoing continuous technological advancements, with many incorporating remote monitoring capabilities. Users can view the pump’s operating status in real time via mobile phones or computers, and remotely start and stop the unit. This not only significantly enhances user convenience but also provides a reliable solution for unattended operation. Through IoT integration, the units can collect and analyze data, helping users predict maintenance cycles and avoid water supply interruptions or firefighting delays caused by equipment failure. Economically, lightweight diesel fire pump units, through structural optimization and improved manufacturing processes, reduce production and maintenance costs, allowing users to obtain high-performance equipment at a lower investment. Their long lifespan, strong operational stability, and excellent overall cost-effectiveness make them a popular choice for government fire departments, industrial enterprises, and construction contractors. Due to its modularity and lightweight design, users have greater flexibility when upgrading or replacing components later, eliminating the need to scrap the entire unit, further reducing long-term costs. Overall, lightweight diesel fire pump units, with their numerous advantages, including rapid deployment, independent power, compact structure, outstanding energy efficiency, and simplified maintenance, have become essential equipment for modern firefighting systems and emergency water supply. They not only provide powerful support in firefighting but also play a vital role in industrial production, agricultural irrigation, flood control and drainage, and other fields. With technological advancements and increasing market demand, this type of equipment will continue to be optimized and upgraded, moving towards greater intelligence, energy conservation, and environmental protection, providing users around the world with more efficient, safe, and reliable firefighting and water supply solutions.

管道泵(不锈钢304316L).jpg)