How to Size a Fire Pump Correctly for Maximum Efficiency

Learn how to size a fire pump accurately by calculating flow demand, pressure requirements, and understanding NFPA 20 guidelines for maximum performance and efficiency.

Choosing the right fire pump size is not just about meeting minimum flow and pressure—it’s about ensuring the pump works efficiently and reliably under all emergency conditions. An incorrectly sized pump can lead to energy waste, system failure, or non-compliance with codes. In this guide, we’ll break down the key factors to help you size a fire pump properly according to NFPA 20 standards.

1. Determine the Required Flow Rate (GPM)

The first step is to calculate the required flow, measured in gallons per minute (GPM). This depends on the type and size of your fire protection system:

-

Sprinkler Systems: Based on the system hazard classification (light, ordinary, or extra hazard).

-

Standpipe Systems: Generally require 500 GPM for the first hose connection and 250 GPM for each additional riser, up to a total of 1000 GPM.

-

Combined Systems: Add up the flow demands of each component.

A fire protection engineer should perform a detailed hydraulic calculation to confirm total demand.

2. Identify Pressure Requirements

Next, calculate the residual pressure your fire pump must provide. This is the minimum pressure needed at the most remote device (like a sprinkler head or hose outlet) to function effectively. Consider:

-

Elevation losses (0.433 psi per foot)

-

Friction losses in the piping

-

Pressure needed at the sprinkler/standpipe outlet

Add all these to get the total required discharge pressure.

3. Analyze Available Water Supply

Compare your required pump performance with the available water supply:

-

Use hydrant flow tests to determine static and residual pressure.

-

If the water supply can’t meet the required pressure, your fire pump must make up the difference.

This comparison determines the net pressure the fire pump must deliver.

4. Select a Pump That Meets Flow and Pressure Needs

Choose a fire pump that:

-

Meets or exceeds the required GPM at the necessary net pressure.

-

Can operate at 150% of its rated flow without dropping below 65% of rated pressure (per NFPA 20).

-

Has a shutoff (churn) pressure less than 140% of rated pressure.

Avoid oversizing, which can lead to high energy consumption, or undersizing, which risks inadequate fire protection.

5. Consider Pump Type and Application

Your building layout and water source may influence the pump type:

-

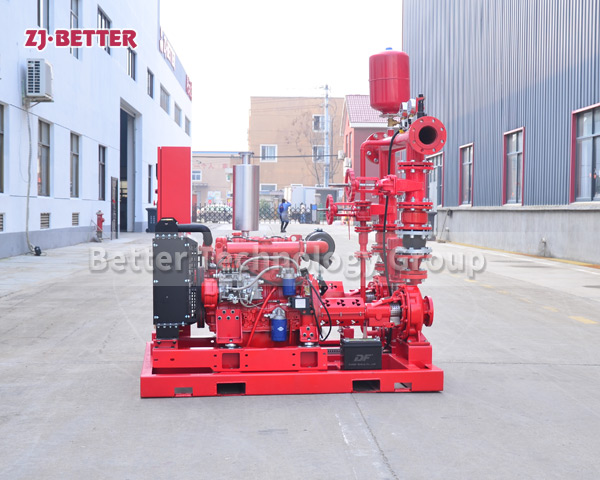

Horizontal Split Case Pump: Ideal for high flow and easy maintenance.

-

Vertical Inline Pump: Good for tight spaces and smaller flow demands.

-

End Suction Pump: Efficient for low-pressure applications.

-

Vertical Turbine Pump: Required if your water source is below pump level (e.g., underground tanks or wells).

6. Check for Power Supply Compatibility

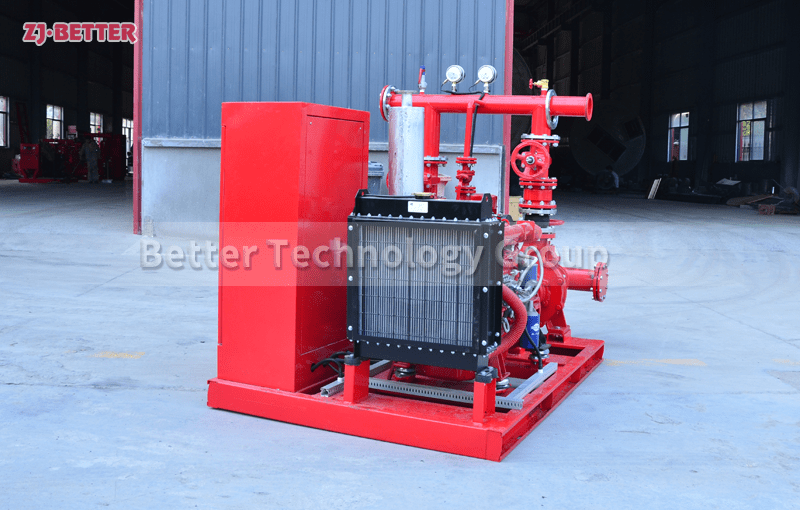

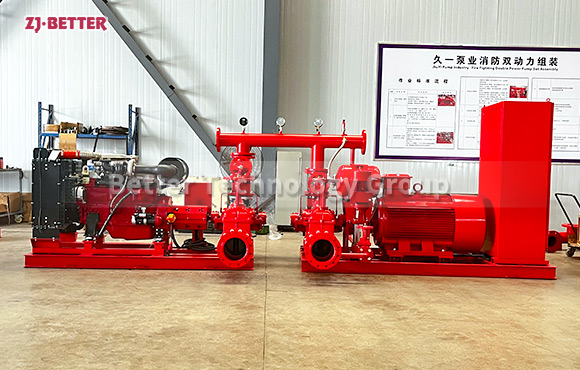

Once you’ve chosen the pump size, make sure the electric motor or diesel engine has the correct power capacity to drive it efficiently. For diesel pumps, verify that fuel tanks and ventilation meet code.

7. Confirm NFPA 20 Compliance

Always verify that your selected pump and system design comply with NFPA 20. Requirements cover:

-

Minimum and maximum performance characteristics

-

Controller compatibility

-

Pipe sizing and layout

-

Relief valves and testing ports

Conclusion

Proper sizing of a fire pump isn’t guesswork—it requires precise calculation, system analysis, and code compliance. By understanding your building’s fire protection needs and available water supply, you can select a pump that delivers maximum performance with energy efficiency and reliability. Always consult a licensed fire protection engineer to verify your calculations and pump selection.