Application Advantages of High-Efficiency Electric Motor Fire Pump Systems in Automatic Fire Protection

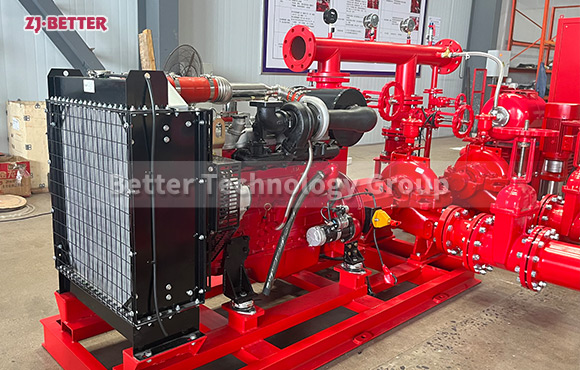

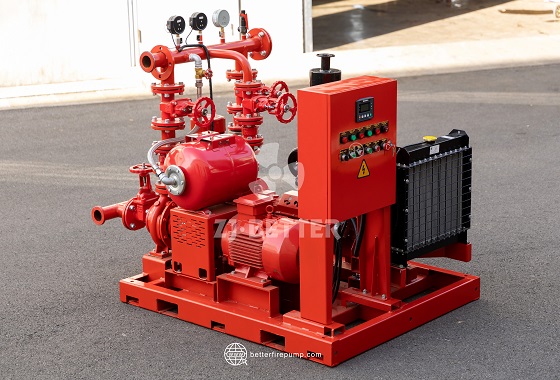

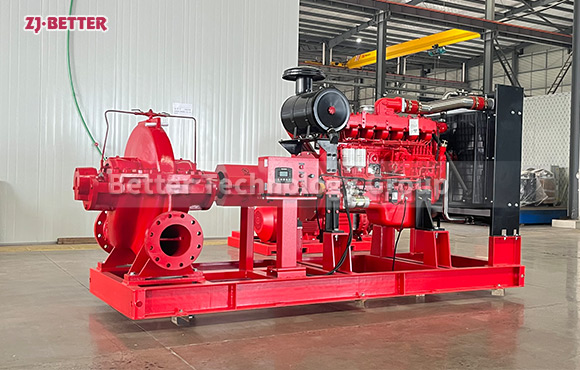

High-efficiency electric motor fire pump systems designed for automatic fire protection, delivering stable pressure, reliable continuous operation, fast response, integrated control, and dependable performance for commercial, industrial, and building fire safety systems.

The advantages of high-efficiency electric motor fire pump systems in automatic fire protection systems are mainly reflected in their stable, continuous, and predictable water supply capacity. These systems typically use electric motors as the primary power source, achieving reliable water supply to building fire protection networks through precisely matched pump structures and control systems. They are indispensable core equipment in modern automatic fire protection systems. Compared to internal combustion engines, electric motor drives offer significant advantages such as smoother operation, lower noise, and faster start-up response. Upon receiving a fire control signal, the motor can reach its rated speed in a very short time, providing continuous and stable pressure support for sprinkler systems, fire hydrant systems, or water curtain systems, thus ensuring that fire extinguishing equipment can function effectively in the early stages of a fire. To meet the dual requirements of automatic fire protection systems for long service life and instantaneous high-load operation, electric motor fire pumps emphasize a balance between structural reliability and operational efficiency during the design phase. The pump body is typically made of high-strength cast iron or wear-resistant alloy materials, and the internal flow channels are optimized to reduce water flow resistance and energy loss, enabling the system to maintain high efficiency under rated operating conditions while reducing energy consumption during long-term operation. Automatic fire suppression systems often require fire pumps to have excellent repeated start-up capabilities. Motor-driven fire pumps excel in this regard, as their motors can withstand frequent starts without significant power attenuation or performance instability. Combined with well-designed control logic, this ensures reliable system operation even during repeated tests or actual fires. The integrated design of the control system is a key advantage of high-efficiency motor-driven fire pump systems. Control cabinets typically integrate power management, operational status monitoring, fault alarms, and manual/automatic switching functions, allowing the fire pumps to remain on standby even under unattended or remote control conditions. Upon detecting abnormal pipeline pressure or receiving a fire signal, the system automatically starts and enters a stable operating state, significantly improving the overall fire response speed. To ensure stable output under different load conditions, motor-driven fire pump systems are typically selected and configured with precise calculations based on building height, pipeline resistance, and water demand. This ensures that the flow rate and head remain within a reasonable range during actual operation, avoiding problems such as insufficient pressure or excessive energy consumption due to improper selection. In terms of long-term operational reliability, high-efficiency motor-driven fire pump systems effectively reduce mechanical wear and the probability of failure by employing high-quality bearings, wear-resistant sealing structures, and reasonable lubrication and heat dissipation designs. Even after years of standby or periodic testing, they can still maintain good starting performance and operational stability. For automatic fire suppression systems, the continuity of water supply is crucial. Motor-driven fire pumps can operate uninterruptedly for extended periods under stable power conditions, ensuring a continuous water supply to the fire suppression network during the ongoing fire phase. This is particularly critical in large commercial buildings, industrial plants, and public facilities. In terms of system structure, motor-driven fire pumps typically adopt an integrated base design, fixing the pump body, motor, and related accessories to the same foundation. This not only improves overall rigidity but also simplifies installation and alignment, helping to reduce operational hazards caused by vibration or installation errors. To adapt to the application needs of different automatic fire suppression systems, these fire pump systems offer high flexibility in configuration. Different specifications of motor power, control methods, and monitoring components can be matched according to project requirements, thereby achieving seamless integration with various fire control systems. In terms of maintenance and management, high-efficiency electric motor fire pump systems also have significant advantages. Routine maintenance mainly focuses on conventional items such as electrical connection checks, bearing lubrication, and operating parameter monitoring. It does not require complex fuel management or startup preparation, reducing maintenance difficulty and operating costs, and ensuring the equipment maintains a high overall cost-effectiveness throughout its service life. In summary, high-efficiency electric motor fire pump systems, with their stable power output, mature control technology, and structural design adapted to the long-term operation requirements of automatic fire suppression systems, provide a reliable water source for building fire protection. Their advantages in automatic start-up, continuous water supply, and low maintenance costs make them a widely adopted and important type of equipment in modern fire protection engineering, playing an irreplaceable role in ensuring the safety of personnel and property.